Construction method of soft surrounding rock four-line super-large section railway tunnel

A technology of super large cross-section and weak surrounding rock, applied in tunnels, tunnel lining, excavation, etc., can solve the problems of supporting subsidence deformation, speeding up construction period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

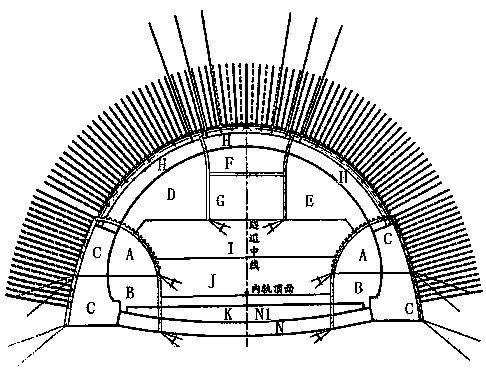

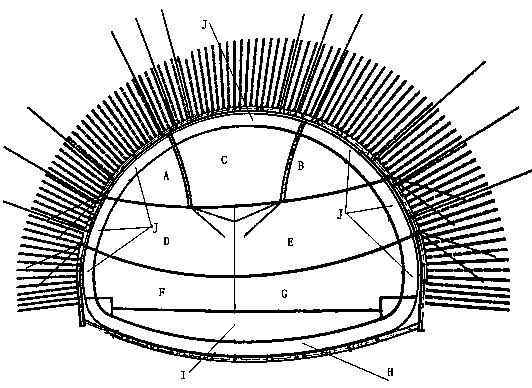

[0128] The present invention is realized through the following technical solutions, as figure 1 , figure 2 As shown, the construction method of the four-line super-large section railway tunnel with weak surrounding rock specifically includes the following steps:

[0129] Step S1: hole construction; specifically includes the following steps:

[0130] Step S11: Build a flat structure with a super large section in the soft rock, and use anchor cable frame beams to reinforce the slope; build a flat structure with a super large section tunnel in the soft rock, and use anchor cable frame beams to reinforce the slope to ensure the stability of the slope;

[0131] Step S12: adopt the advance support of the double-sided large pipe shed;

[0132] Step S13: Excavating the pilot pit with composite double side walls; construction is carried out after the slope body at the entrance is reinforced, the tensioning of the anchor cables is completed, and the construction of the large pipe she...

Embodiment 2

[0144] This embodiment is further optimized on the basis of the above embodiments. Further, in order to better realize the present invention, the step S11 specifically includes the following steps:

[0145] Step A1: drainage system construction;

[0146] Step A2: Slope brushing construction; specifically refers to: slope brushing is carried out from top to bottom, using large-scale mechanical equipment to brush the slope and manually repairing the slope; carrying out protective construction on the slope, one layer of slope brushing, and one layer of slope protection construction ;

[0147] Step A3: Anchor cable drilling construction; set up the drilling operation platform, and set up maintenance railings around the drilling operation platform; the hole opening deviation is not greater than 20cm, the hole depth is not less than the design length, the drilling direction is consistent with the design method, and the hole The direction deviation is not more than 1.5°; during the ...

Embodiment 3

[0179] This embodiment is further optimized on the basis of the above embodiments, and the step S12 specifically includes the following steps:

[0180] Step B1: guide pipe installation and construction;

[0181] Step B2: Concrete construction of the guide wall; specifically refers to: setting a φ133 guide sleeve in the guide wall, the guide sleeve and the guide wall are welded with an I20b I-shaped steel frame, and the outer insertion angle of the guide sleeve is 1°;

[0182] Step B3: Drilling platform construction; the drilling platform is erected by sensory scaffolding or filling;

[0183] Step B4: use a drilling rig for drilling construction; when the concrete strength of the guide wall reaches 75% of the design strength, carry out drilling construction; before drilling, the axis of the drill rod of the drilling rig is on a straight line with the axis of the set guide pipe; use low speed Low-pressure drilling, the drilling speed and wind pressure can be gradually adjusted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com