External support replacement type room type coal pillar recycling method

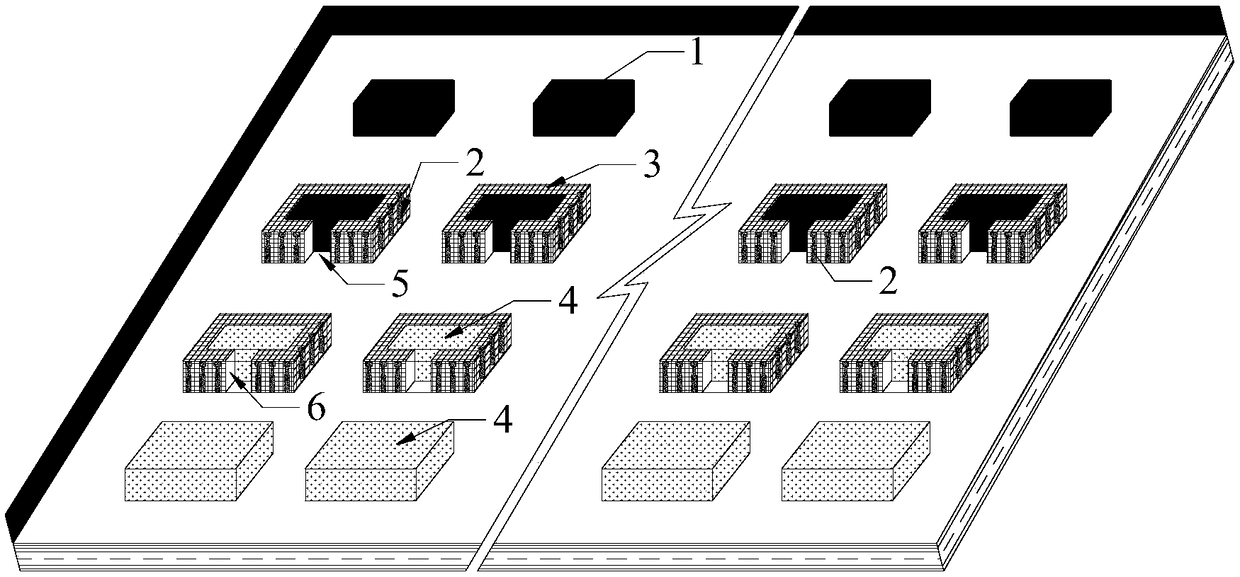

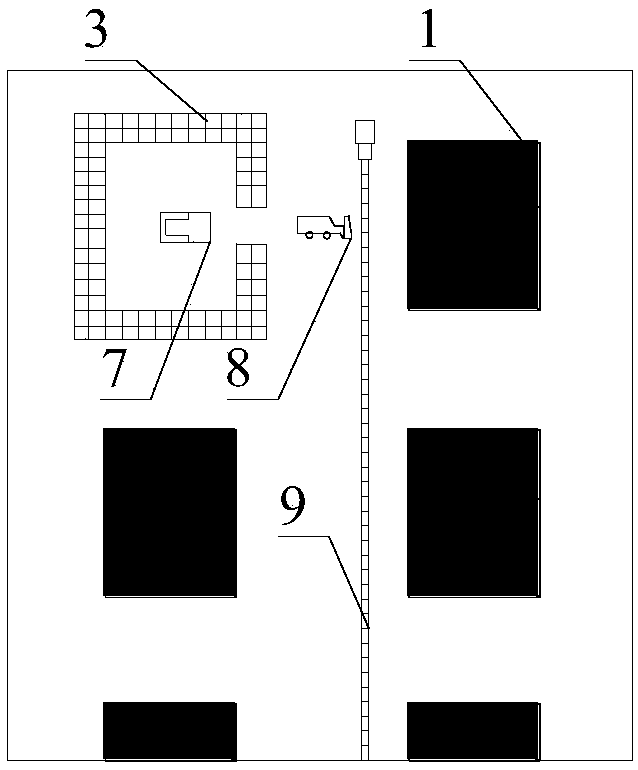

一种房式煤柱、回收方法的技术,应用在支柱/支架、土方钻采、充填物等方向,能够解决设备和充填物料投入高、机械化程度不高、效率低等问题,达到保护地表生态环境、支护性能好、广泛应用前景的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

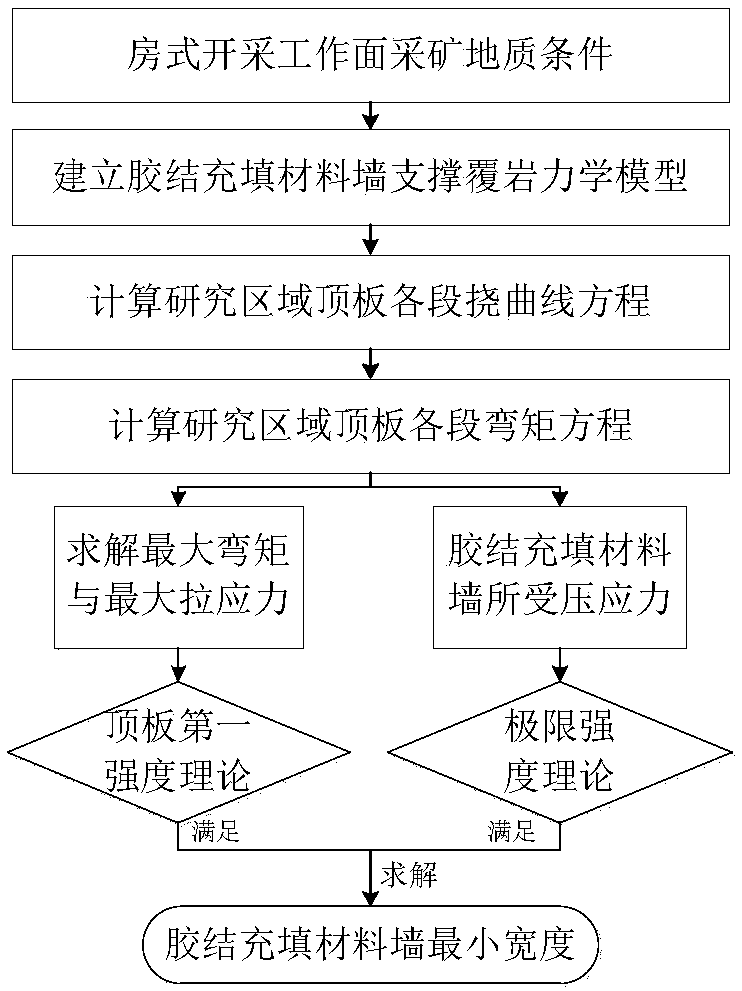

[0085] Using the above solution method, combined with the geological conditions of a mine in Northwest China as an example, the roof thickness of the mine is 2m, the mining height is 4m, the length of the coal pillar is 2m, the length of the coal room is 10m, the elastic modulus of the roof is 0.9GPa, and the cemented filling material wall foundation Factor 1.5×10 6 N / m 3 , The allowable tensile stress of the roof is 2.8MPa, the ultimate strength of the cemented filling material wall is 39MPa, and the uniformly distributed load q=2MPa. Judging by formula (v), when the width of the cemented filling material wall is 3m, the bending moment distribution of the roof is as follows: Figure 5 As shown, the maximum tensile stress value of the roof at this time is 2.2MPa, the roof will not break, and the compression curve of the cemented filling material wall is drawn, see Figure 6 , it can be seen from formula (vi) that the resultant force acting on the cemented filling material wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com