Downhole driven reciprocating pump oil recovery device

A technology for oil production equipment and reciprocating pumps, applied in electromechanical equipment, pumps, production fluids, etc., can solve the problems of increased workover operations and increased costs, and achieve the effects of improving efficiency, reducing costs, and eliminating transmission losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in detail below in conjunction with accompanying drawing.

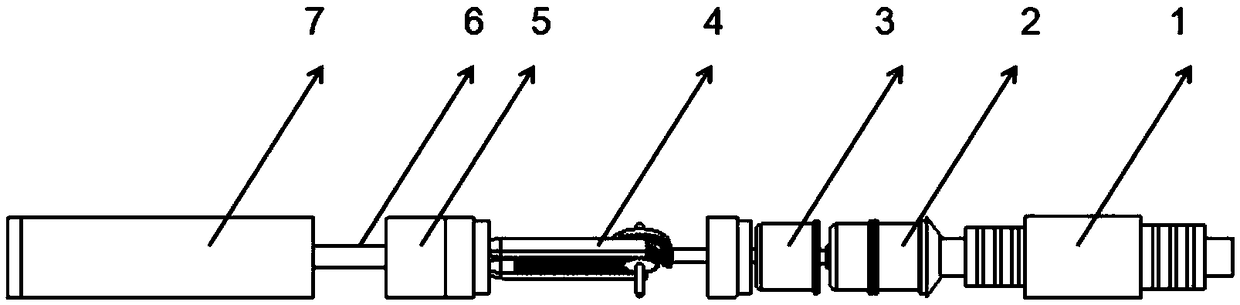

[0014] refer to figure 1 , an oil production device driven by a downhole reciprocating pump, comprising a rotating motor 1, a planetary reducer 2, an incomplete gear reversing mechanism 3, an intermediate transmission mechanism 4, a protector 5 and a plunger pump 7;

[0015] The power output end of the rotating electrical machine 1 is connected to the power input end of the planetary reducer 2, the power output end of the planetary reducer 2 is connected to the power input end of the incomplete gear reversing mechanism 3, and the power of the incomplete gear reversing mechanism 3 The output end is connected with the power input shaft 8 of the intermediate transmission mechanism 4 , and the power output end of the intermediate gear transmission mechanism 4 is connected with the piston rod 6 of the plunger pump 7 .

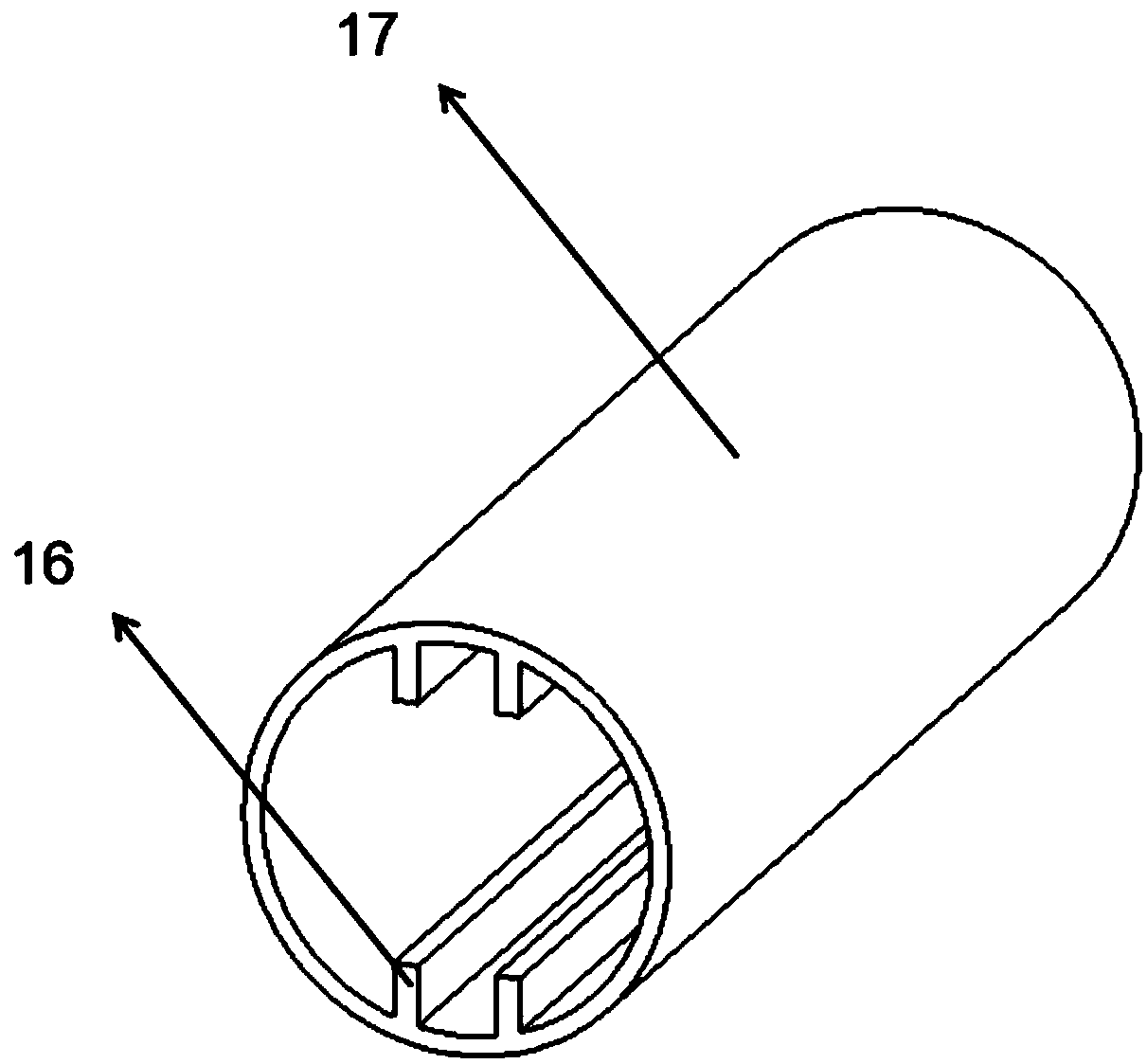

[0016] refer to figure 2 and image 3 , the intermediate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com