Long blade torsion resistant window blind

A louver and long-blade technology, which is applied in the field of long-blade torsion-resistant louvers, can solve problems such as easy distortion and deformation of louver blades, uneven gaps between louver blades, and expansion of deformation, so as to achieve fewer transmission structures, reduce deformation, and reduce maintenance. The effect of frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

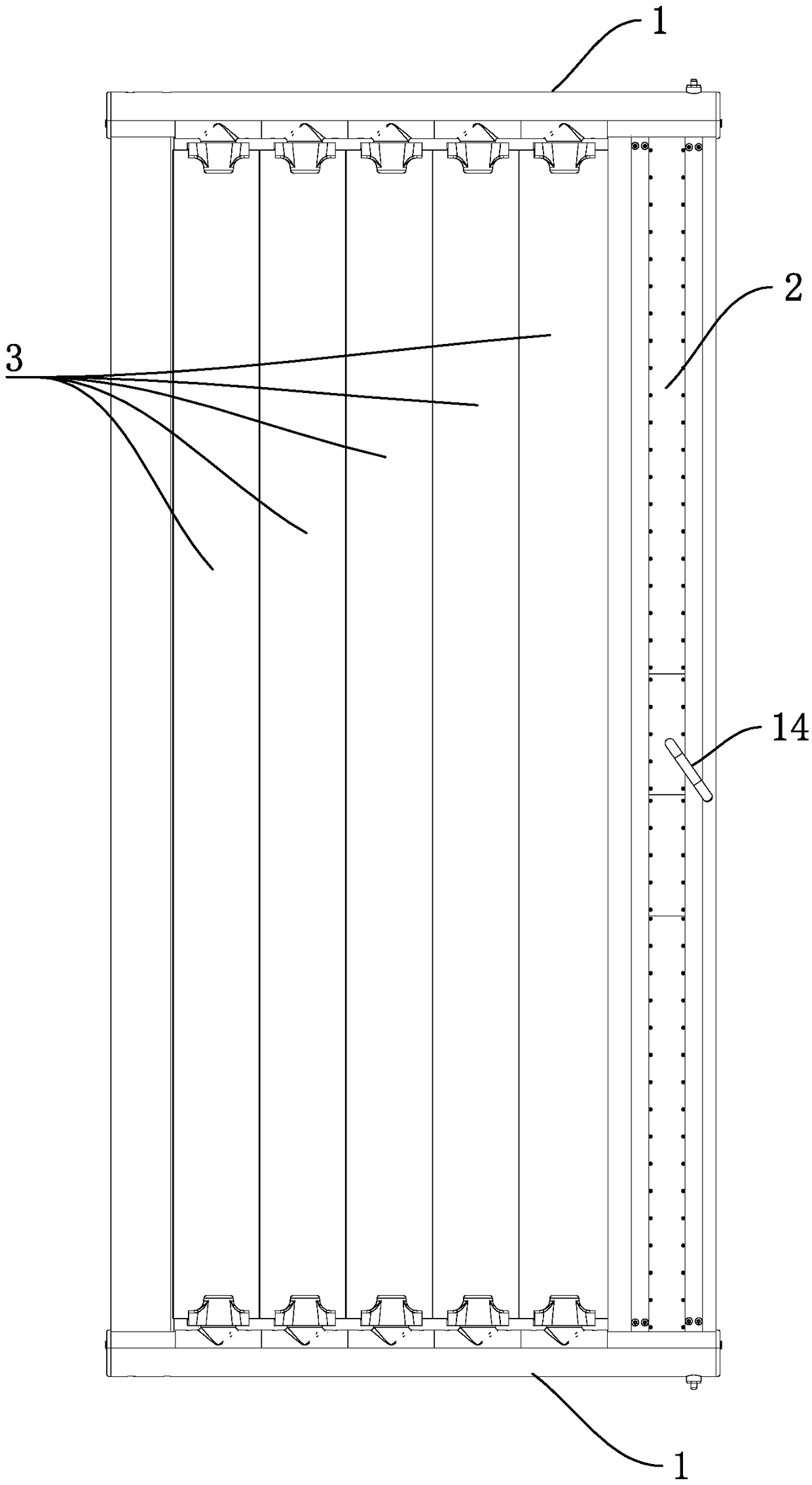

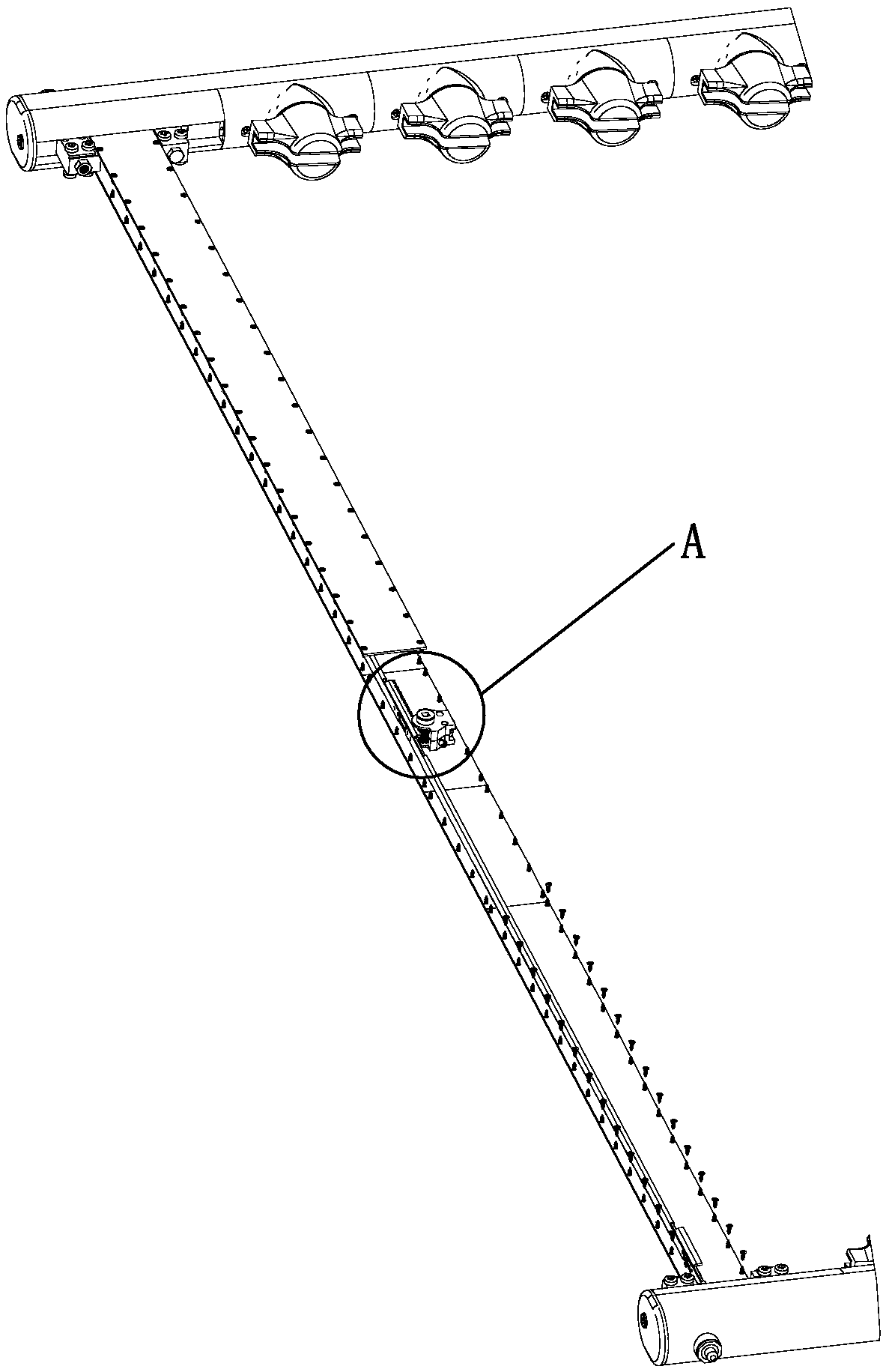

[0036] Embodiment: a kind of anti-torsion blinds with long blades, such as figure 1 As shown, it includes two window frames 1 parallel to each other, several blades 3 are vertically installed between the two window frames 1, and a transmission box frame 2 is also connected between the two window frames 1. The transmission box frame 2 is provided with a driving structure for driving the shutters to rotate, and the window frame 1 is provided with a transmission structure.

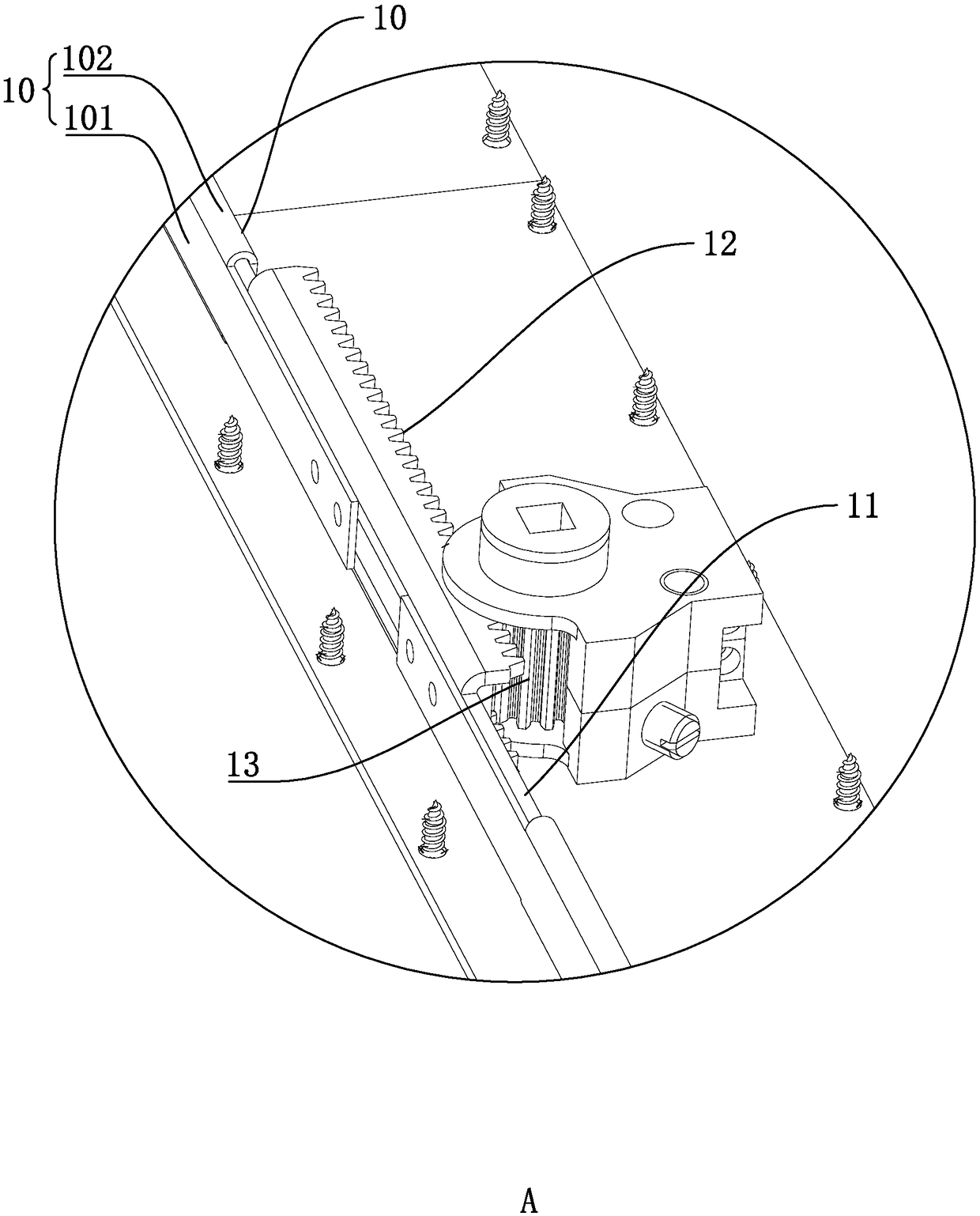

[0037] Such as image 3 As shown, the moving structure includes a second spur rack 12 and a second gear 13 that mesh with each other, and a handle 14 is installed on the outer surface of the transmission box frame 2 (see figure 1 ), the handle 14 is extended in the transmission box frame 2 to connect the second gear 13, turning the handle 14 can drive the second gear 13, and the second gear 13 pushes the second spur rack 12 to move. A second rail 10 is fixed inside the transmission box frame 2 , and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com