Preparation method of Pd-In-Fe elastic-thermal refrigerating material with linear superelasticity

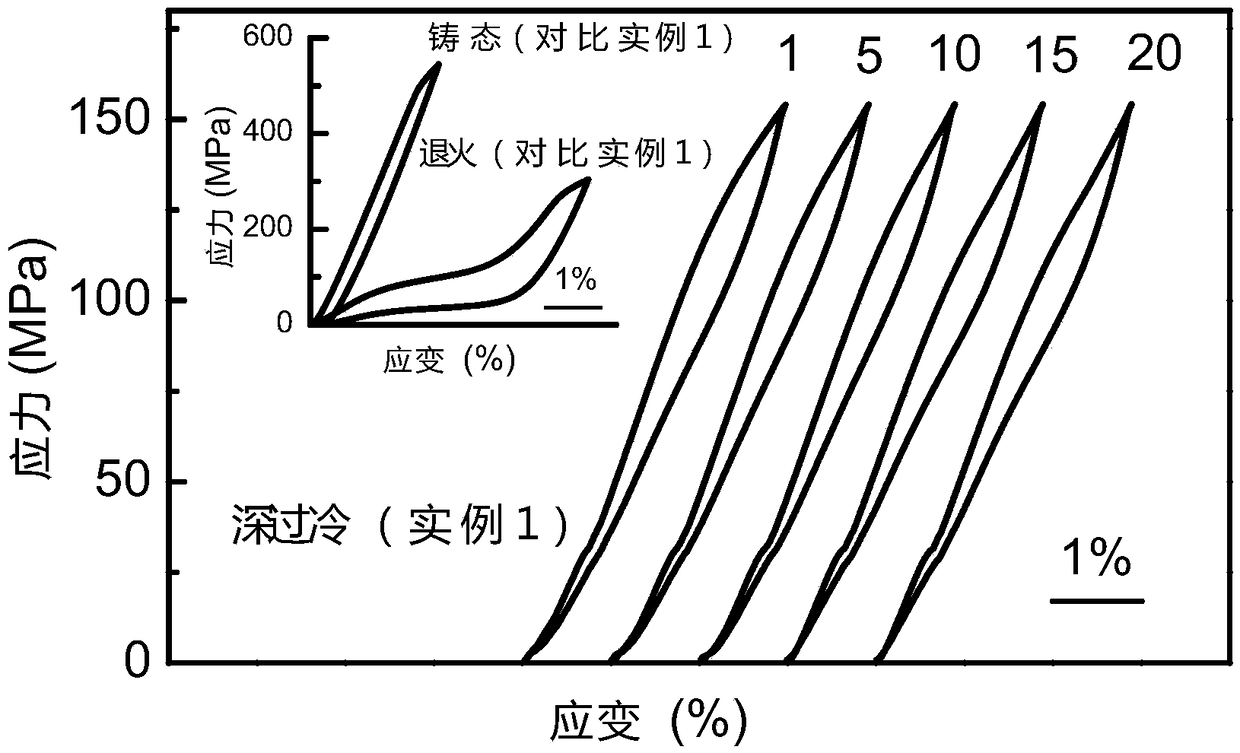

A pd-in-fe, superelastic technology, applied in the field of preparation of Pd-In-Fe type elastocaloric refrigeration materials, can solve problems not involved in the research of deep subcooling treatment, and achieve improved refrigeration efficiency and small hysteresis of linear superelasticity , good reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In this embodiment, the elastothermal refrigeration alloy material is Pd 59.3 In 23.2 Fe 17.5 , same as Comparative Example 1. In this embodiment, the Pd-In-Fe type elastothermal refrigeration alloy is prepared by using the deep subcooling technology of molten glass and cyclic superheating treatment, and the specific preparation process is as follows:

[0044] (1) exactly the same as step (1) in comparative example 1, obtain alloy ingot;

[0045] (2) Get about 6g of this alloy ingot sample and pack into a quartz crucible, select commercial NiSiGa glass as a purifier, put the alloy ingot into a quartz crucible, fully coat the alloy ingot with a glass purifier, the glass purifier Components and their mass percent content are: SiO 2 The content is 74.0%, Na 2 O and K 2 The mixture content of O is 15%, CaO content is 7%, Al 2 o 3 content of 2%, MgO content of 1.8%, and Fe 2 o 3 The content is 0.2%.

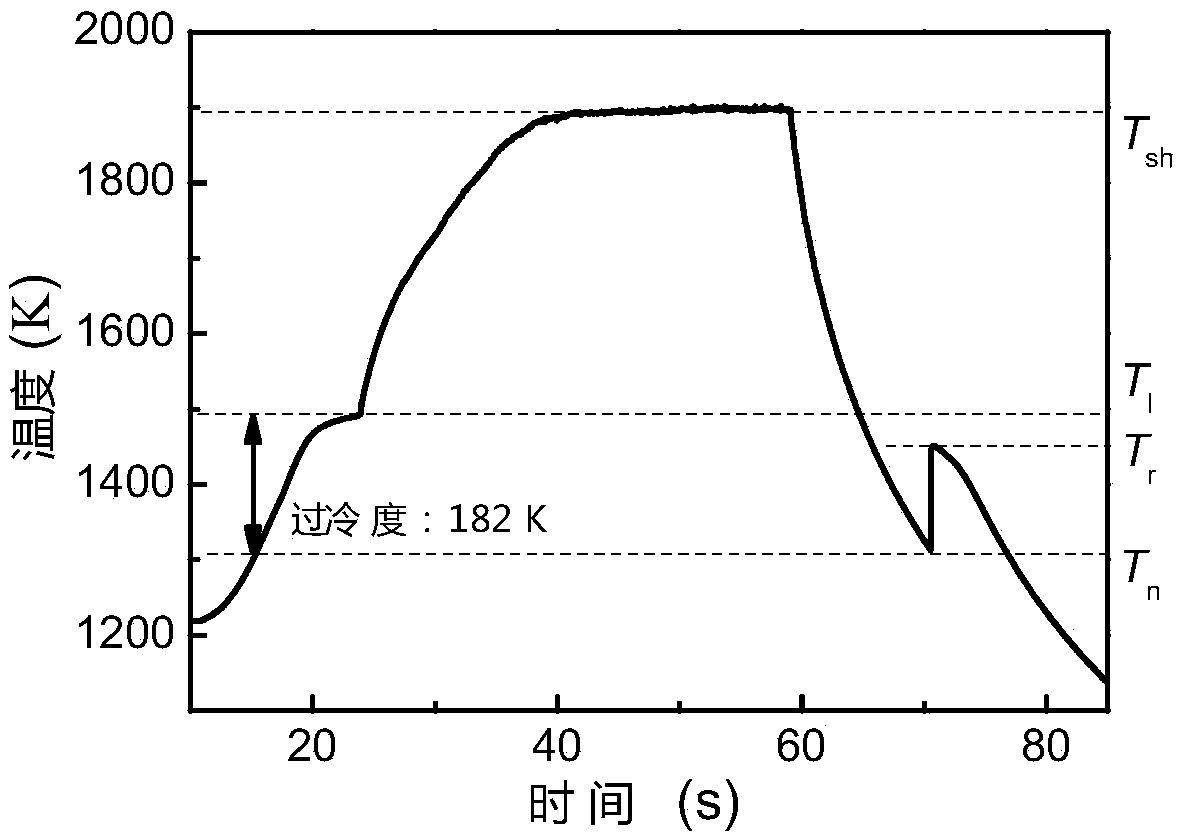

[0046] Fix the quartz crucible in the induction coil of the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com