One-component self-drying water-based hammer paint and preparation method thereof

A self-drying, one-component technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of high VOC content in paints, affect product promotion, and high construction costs, and achieve the effect of simple construction, convenient construction, and improved workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

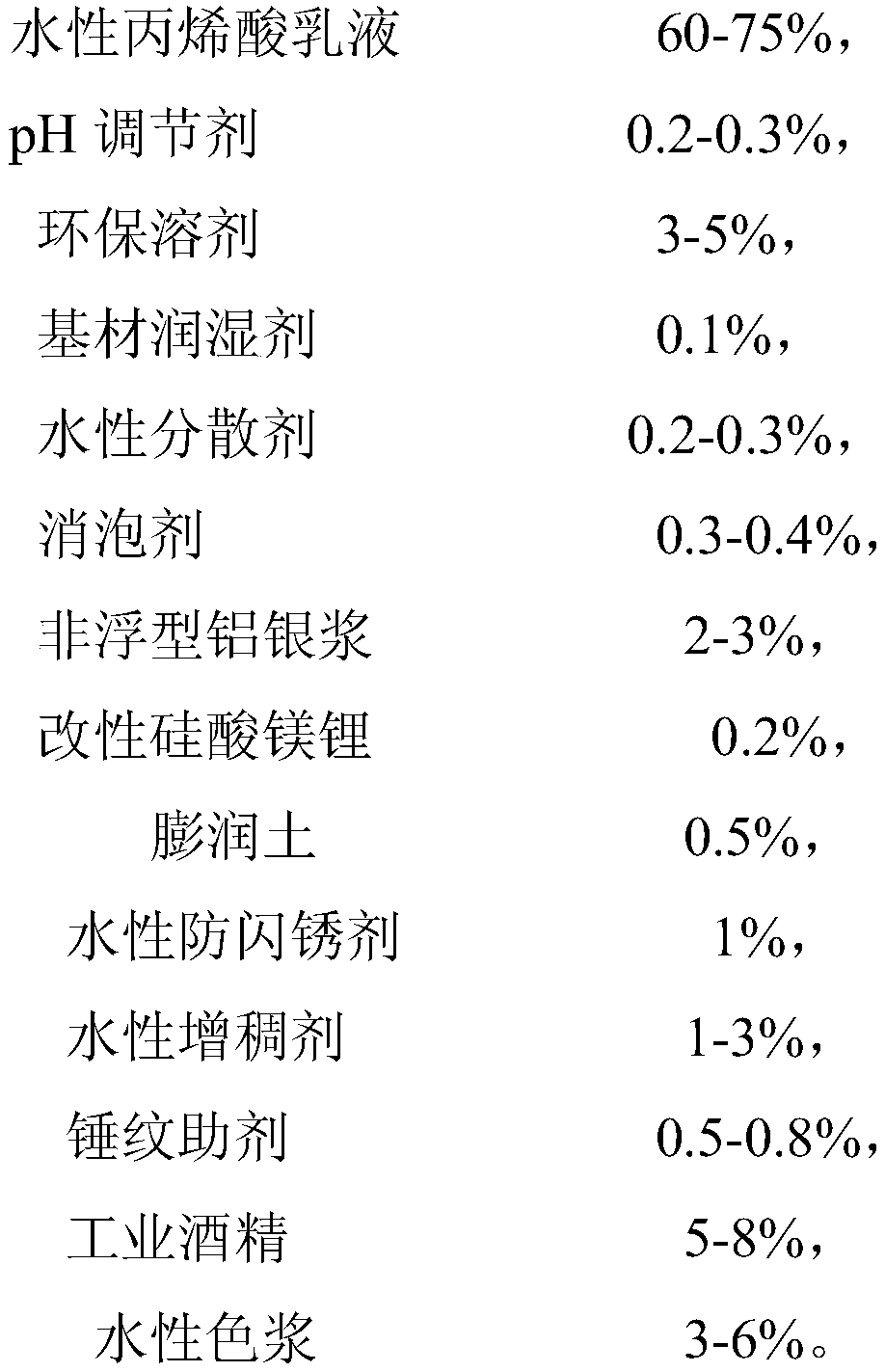

[0023] A kind of one-component self-drying type water-based hammer grain paint of the present invention, described single-component self-drying type water-based hammer grain paint comprises the following components in parts by mass:

[0024]

[0025]

[0026] The water-based acrylic emulsion is ALBERDINGK self-crosslinking two-phase core-shell structure water-based acrylic dispersion AC2403. The environment-friendly co-solvents are HC-500 and Suitai SeikosolvBP-15 of High Chemical Co., Ltd., and the ratio of HC-500 and Suitai SeikosolvBP-15 of High Chemical Co., Ltd. is 2:3.

[0027] The HC-500 is a non-toxic, odorless, slow-volatile, environmentally friendly solvent, and the BP-15 is a mild and light multifunctional alcohol ester solvent.

[0028] The defoamer is a mixture of Tego901W of Tego and BYK-024 of BYK, the mixing ratio is 1:1; the wetting agent of the substrate is Tego510 of Tego; the water-based dispersant is gas Chem CT-324. The modified lithium magnesium ...

Embodiment 2

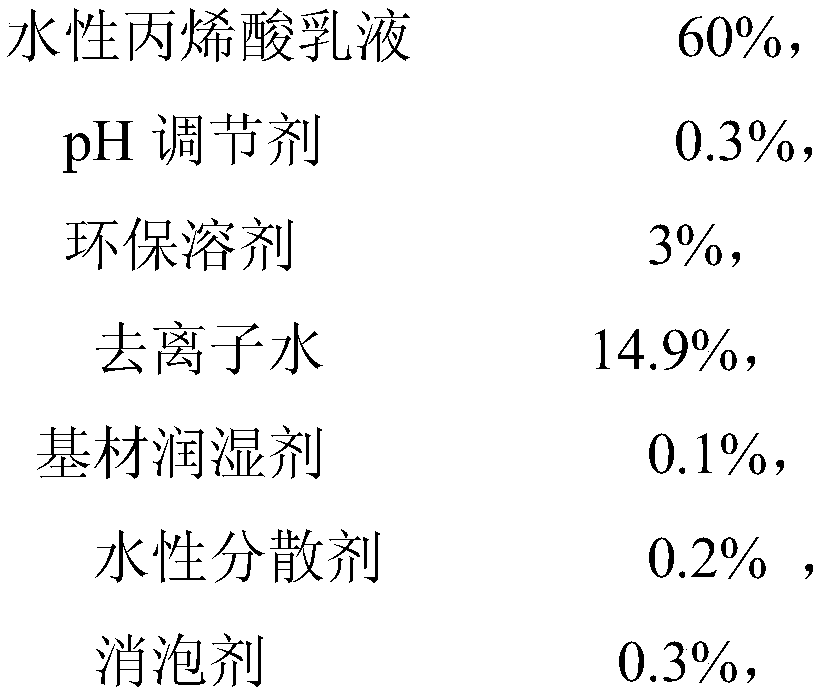

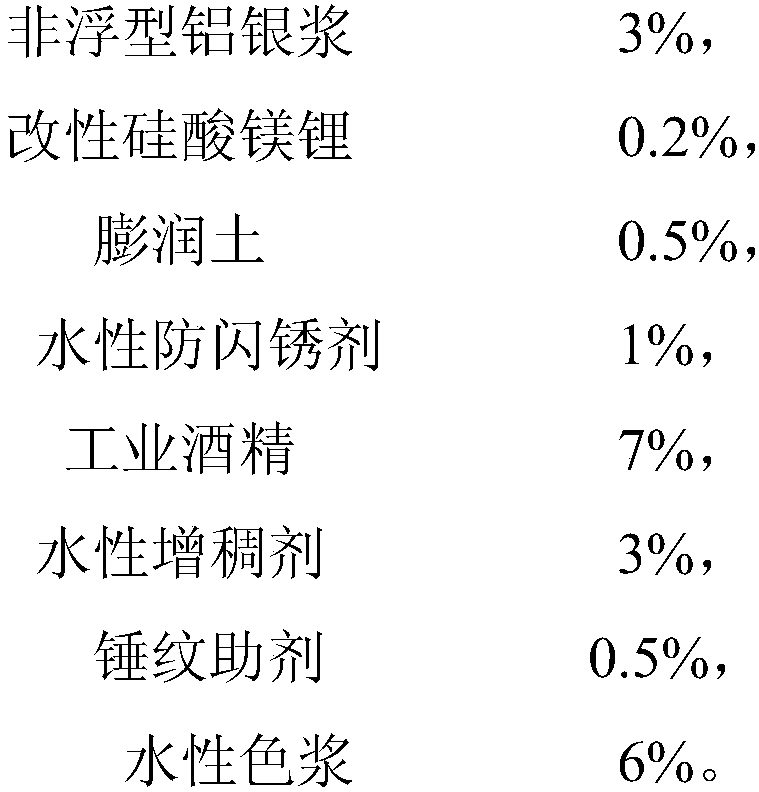

[0036] The difference between embodiment 2 and embodiment 1 is: a kind of one-component self-drying type water-based hammer grain paint of the present invention, described one-component self-drying type water-based hammer grain paint comprises the following components in parts by mass composition:

[0037]

[0038]

[0039] The preparation method of one-component self-drying type water-based hammer grain paint of the present invention may further comprise the steps:

[0040] In step (1), according to the raw material ratio, the water-based acrylic emulsion is added to the stock preparation pot, and stirred at a speed of 600r / min for 5 minutes;

[0041] In step (2), then the pH regulator is added to the stock preparation pot, stirred at 700r / min for 5min, the mixture of deionized water and environmentally friendly solvent is added to the stock preparation pot, and stirred at a speed of 600r / min for 10 minutes;

[0042] In step (3), then add defoamer, water-based dispersa...

Embodiment 3

[0044] The difference between embodiment 3 and embodiment 1 is: a kind of one-component self-drying water-based hammer grain paint of the present invention, described one-component self-drying type water-based hammer grain paint comprises the following components in parts by mass composition:

[0045]

[0046]

[0047] The preparation method of one-component self-drying type water-based hammer grain paint of the present invention may further comprise the steps:

[0048] In step (1), according to the raw material ratio, the water-based acrylic emulsion is added to the stock preparation pot, and stirred at a speed of 560r / min for 5 minutes;

[0049] In step (2), then the pH regulator is added to the stock preparation pot, stirred at 600r / min for 5min, the mixture of deionized water and environmentally friendly solvent is added to the stock preparation pot, and stirred at a speed of 800r / min for 10 minutes;

[0050] In step (3), then add defoamer, water-based dispersant, mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com