A kind of preparation method and device of 2,3,3,3-tetrafluoropropene

A technology of tetrafluoropropene and tetrafluoropropane, which is applied in the field of preparation of 2,3,3,3-tetrafluoropropene, can solve the problems of low reaction selectivity, difficult product separation, low conversion rate, etc., and achieve the total conversion rate High, overcome difficult to separate, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

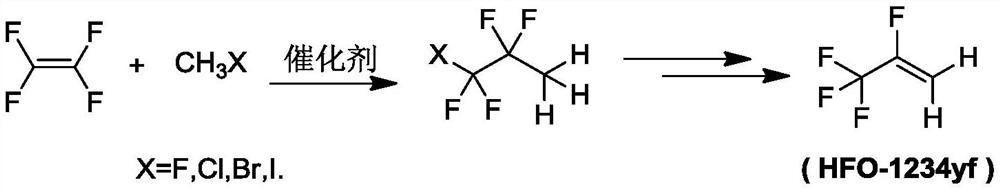

[0085] (1) Preparation of raw material 1,1,1,3-tetrachloro-2,2,3,3-tetrafluoropropane (CFC-214cb) by addition of tetrafluoroethylene and carbon tetrachloride:

[0086] CCl 4 +TFE→CFC-214cb

[0087] In a 10L stainless steel autoclave, carbon tetrachloride (10.0kg, 65.0mol) was added, and anhydrous aluminum chloride (0.5kg, 3.7mol) was used to replace three times with tetrafluoroethylene under stirring conditions. Heat the internal temperature to 60-70°C, then feed tetrafluoroethylene (TFE) into the autoclave, maintain the pressure at 3-5 atm, until the reaction system does not absorb tetrafluoroethylene, stir the reaction for about 12 hours, and put the high-pressure After the kettle was cooled to room temperature, the material was discharged, and the obtained material was added to 1.5 L of 2.0 mol / L hydrochloric acid under stirring conditions, stirred, and static liquid separation. The organic phase was separated and purified by rectification using a 1.0-meter-long rectificat...

Embodiment 2

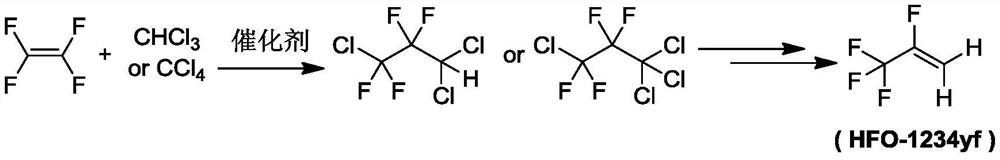

[0095] (1) Preparation of raw material 1,1,3-trichloro-2,2,3,3-tetrafluoropropane (CFC-214cb) by addition of tetrafluoroethylene and chloroform:

[0096] CHCl 3 +TFE→HFC-224ca

[0097] In a 10L stainless steel autoclave, add chloroform (10.0kg, 83.8mol), use anhydrous aluminum chloride (1.12kg, 8.4mol), and under stirring conditions, use tetrafluoroethylene to replace three times, and heat the inner temperature of the reactor to 70-80°C, then feed tetrafluoroethylene (TFE) into the autoclave, maintain the pressure at 5-8 atm, until the reaction system does not absorb tetrafluoroethylene, stir the reaction for about 24 hours, and cool the autoclave to After discharging at room temperature, add the obtained material into 3.4L of 2.0mol / L hydrochloric acid under stirring conditions, stir, and separate liquids at rest. The organic phase is separated and purified by rectification using a 1-meter-long rectification column. Collect 90 ~ Fraction between 93°C, the product 1,1,3-tric...

Embodiment 3

[0105] Alumina-supported catalyst preparation.

[0106] Preparation of Catalyst-1:

[0107] (1) Take 500 g of a spherical alumina carrier with a diameter between 1 and 2 mm, bake it at 450° C. for 4 hours, and store it under dry conditions for later use. Characterization results of physical and chemical properties of the carrier: the specific surface area is 320m 2 / g, the average pore diameter is 9.1nm, the pore volume is 0.73mL / g, the acidity of infrared pyridine adsorption Lewis acid is 0.083mmol pyridine / g (160°C), 0.052mmol pyridine / g (450°C).

[0108] (2) Weigh 150g titanium tetrachloride (TiCl 4 ) was dissolved in 100mL dilute hydrochloric acid (0.1mol / L), and set aside;

[0109] (3) Take 100 g of the above-mentioned calcined alumina carrier in a rotating container (drum), spray 80 mL of dilute hydrochloric acid solution of titanium tetrachloride, and rotate for 20 minutes after the spraying;

[0110] (4) The impregnated catalyst was dried at 120° C. for 4 hours, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com