Solution pressure transformation desorption/compressing refrigeration cycle apparatus

A compression refrigeration and circulation device technology, which is applied in the direction of refrigerators, compressors, refrigeration components, etc., can solve the problems that the refrigeration effect is difficult to improve, and achieve the effects of avoiding adverse effects, improving refrigeration coefficient, and high unit cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

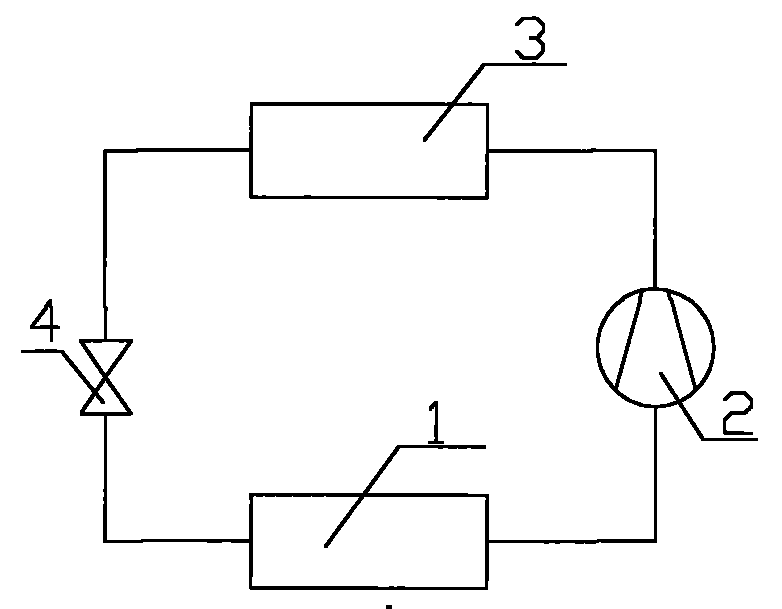

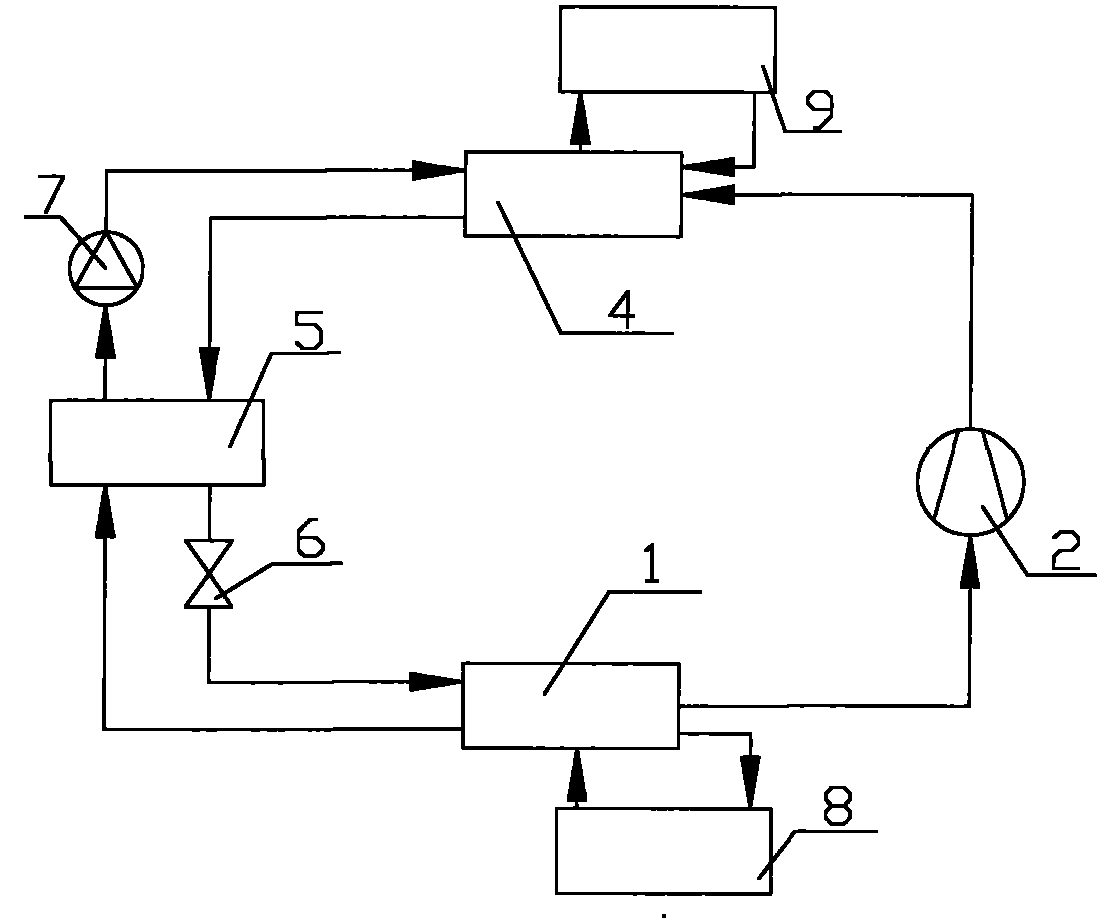

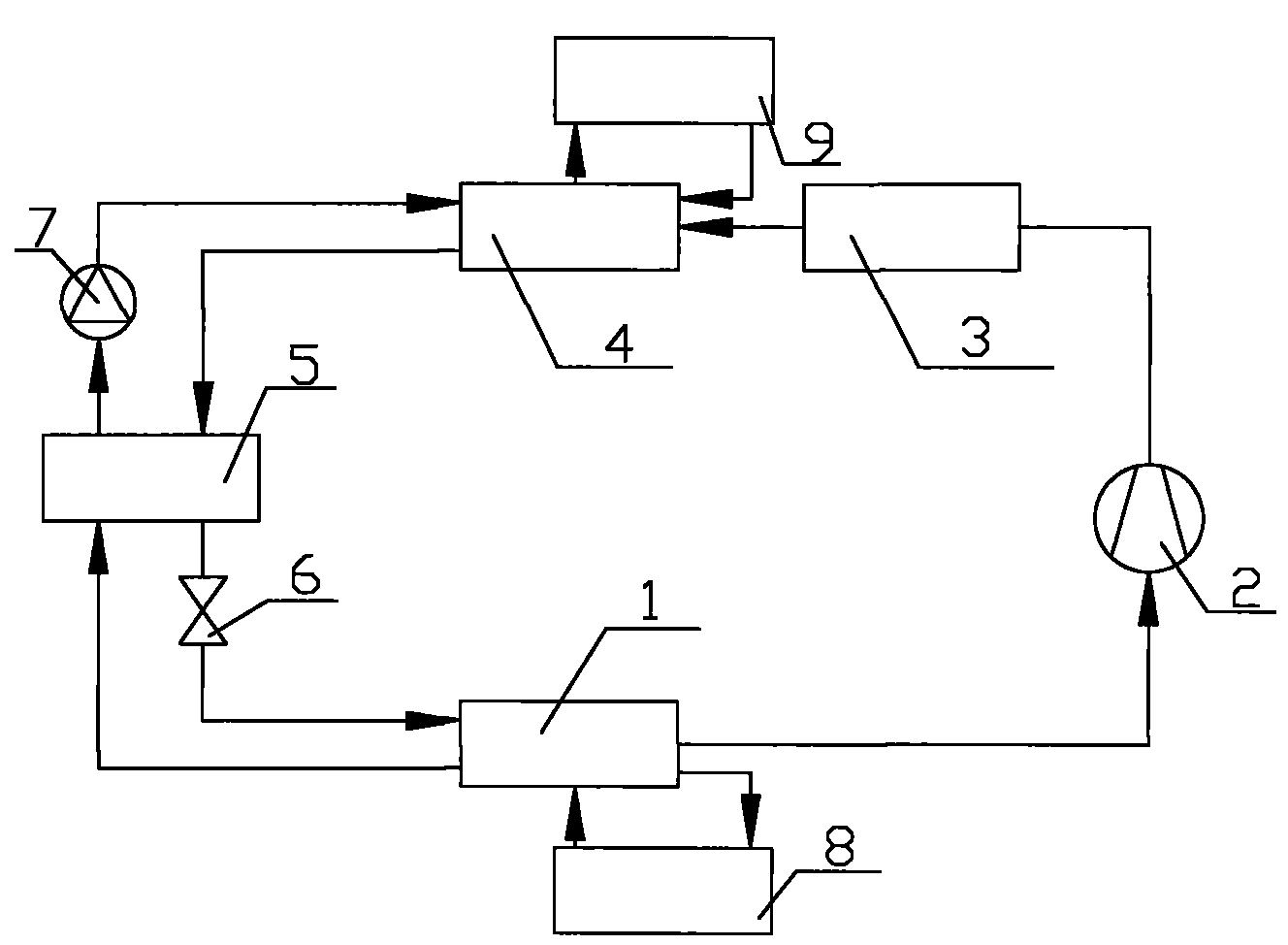

[0027] like figure 1 As shown, the refrigeration cycle device includes a low-pressure generator 1, a compressor 2, an absorber 4, a heat exchanger 5, a throttle valve 6 and a solution pump 7, wherein an inlet of the low-pressure generator 1 passes through a pipeline and the throttle valve 6 One outlet communicates with the inlet of the compressor 2 through a pipeline, and the other outlet communicates with an inlet of the heat exchanger 5 through a pipeline. An inlet and an outlet are also provided on the low-pressure generator 1, which respectively communicate with the low-temperature heat store through pipelines. 8 exports and imports are connected. One inlet of the absorber 4 is communicated with the outlet of the compressor 2 through the pipeline, the other inlet is communicated with the outlet of the solution pump 7 through the pipeline, and one outlet is communicated with the other inlet of the heat exchanger 5 through the pipeline, and the absorber 3 is also provided wi...

Embodiment 2

[0037] like Figure 5 As shown, the horizontal spiral micro-groove tube 11 in the low-pressure generator 1 can be replaced by a wire mesh pipe 11', and a brine is introduced into the wire mesh pipe 11' to take away the cold energy, and the ammonia water entering from the ammonia water inlet is in the wire mesh pipe 11'. Rising film desorption is performed on the network pipe 11' to release ammonia vapor.

[0038] Others are with embodiment 1.

Embodiment 3

[0040] like Figure 6 As shown, the cross-sectional shape of the gas channel 12 at the top of the horizontal spiral microgroove tube 11 and the solution channel 13 at the bottom of the horizontal spiral microgroove tube 11 in the low-pressure generator 1 are sloped, and the slope can play a role in reducing pressure, realizing The generation process of concentrated ammonia solution under isothermal and variable pressure. In order to make the pressures on the same section of the low-pressure generator equal, the slope of the slope of the solution channel 13 is greater than the slope of the slope of the gas channel 12 .

[0041] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com