A pretreatment device system for secondary production of waste glass

A pretreatment device and technology for waste glass, applied in glass production and other directions, can solve the problems of inability to ensure the safety of workers and low work efficiency, and achieve the effects of ingenious design structure, quick installation, and increased production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 Now, a pretreatment device system for the secondary production of waste glass provided by the present invention is described, which includes a rough treatment unit 2 fixed on the frame 1, and the rough treatment unit 2 includes a rough treatment chamber 201, the The sidewalls at both ends of the rough processing chamber 201 are provided with feeding ports 202, and the waistline of the rough processing chamber 201 is designed as a concave waistline extending from the outside of the feeding port 202 to the inside. A conveyor belt 3 for transporting waste glass to the rough treatment chamber 201 is provided, shielding plates 4 are fixed on both sides of the belt body of the conveyor belt 3, and a crushing unit 5 is arranged in the rough treatment chamber 201. The crushing unit 5 includes a single crushing rod 501 and a double crushing rod 502, and the rod walls of the ...

Embodiment 2

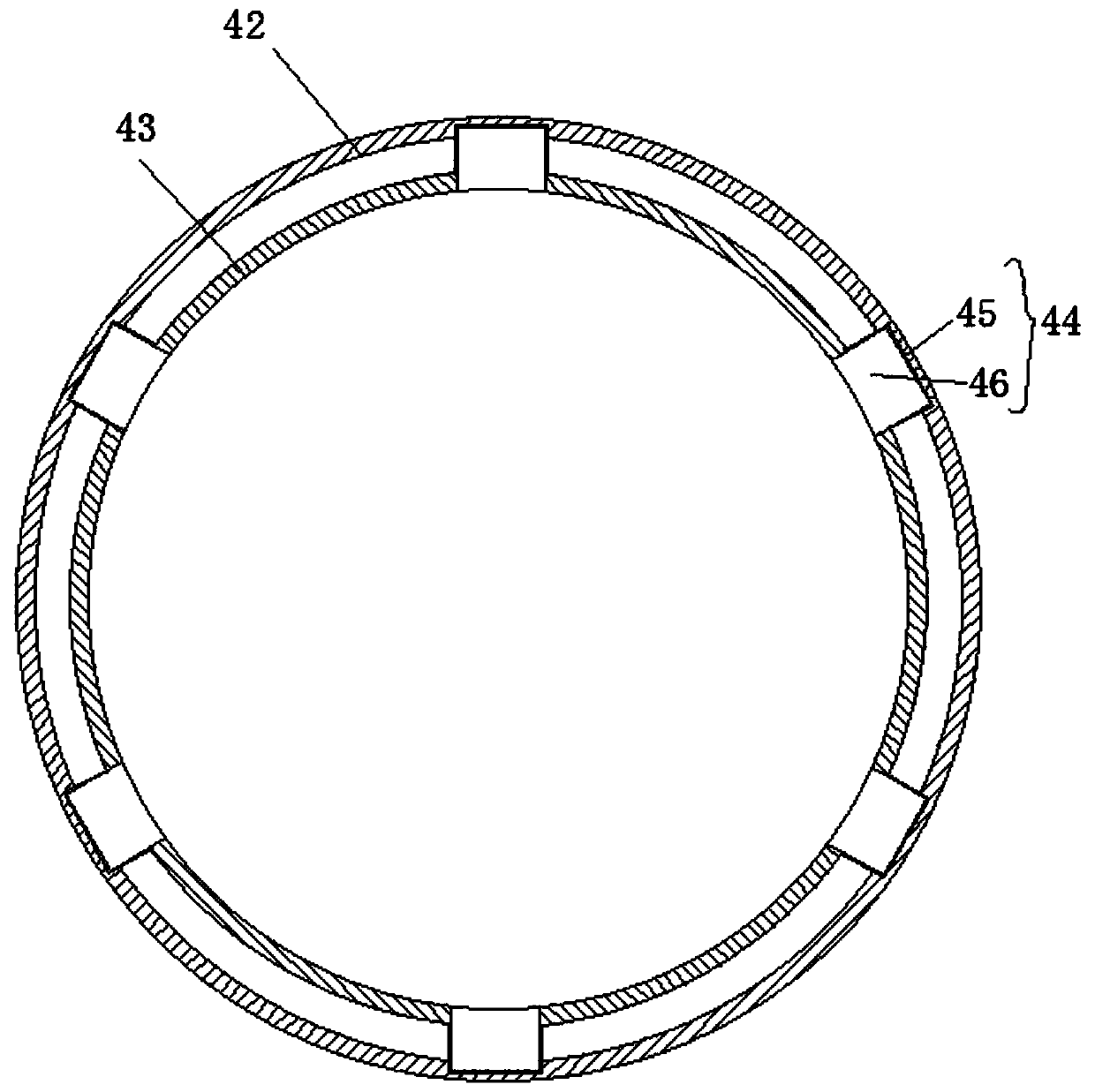

[0032] Example 2: see figure 1 , figure 2 , image 3 and Figure 4 , as an improvement of the present invention, the sleeve structure 6 includes a sleeve assembly 601, the sleeve assembly 601 includes an outer sleeve 42 and an inner sleeve 43, the outer wall of the inner sleeve 43 and the outer wall of the outer sleeve 42 There is a space between the inside, and the outer sleeve 42 and the inner sleeve 43 are connected by a connection structure 44, and the connection structure 44 includes a groove 45 and a protrusion 46 that slides with the groove 45, and the groove 45 is arranged on the inner wall of the outer sleeve 42, and the protrusion 46 is arranged on the outer wall of the inner sleeve 43, and the tube body of the outer sleeve 42 is provided with a hole for embedding the crushing teeth 503 along the direction of its central axis. The installation structure 47, the inner sleeve 43 is integrally connected with the outer wall of the single breaking rod 501 and the doub...

Embodiment 3

[0033] Embodiment 3: see figure 1 , figure 2 , image 3 and Figure 4 , as an improvement of the present invention, the length of the groove 45 is vertically extending from the upper end of the outer sleeve 42 to the lower end of the outer sleeve 42, which is parallel to the central axis of the outer sleeve 42, and the protrusion 43 The length is consistent with the length of the groove 45 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com