System and method for producing electrolytic treatment solutions

An electrolytic treatment and solution technology, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of unstable electrodes, time-consuming and labor-intensive, low oxidant concentration, etc. Simple and ingenious, the method is easy to apply, and the effect of good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

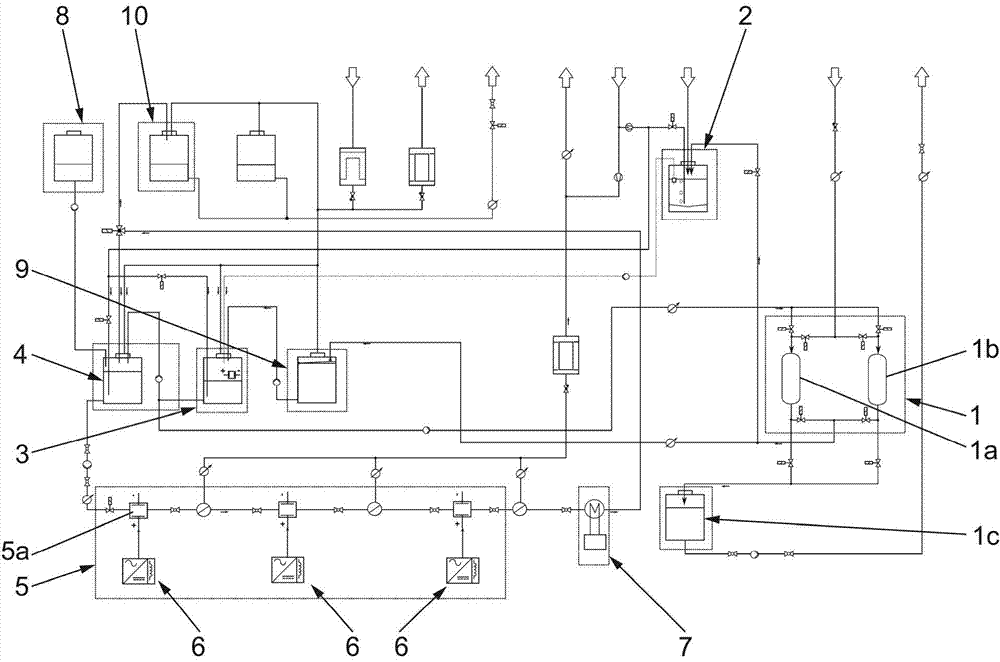

[0056] The invention relates to a system for producing an electrolytic treatment solution comprising at least one single-chamber electrolytic cell designed as a flow and at least one electrode. The invention also relates to a method for producing an electrolytic treatment solution using the system. For other features and details of this embodiment and the corresponding advantages, please refer to figure 1 shown.

[0057] Further introduce the present invention with a specific embodiment below:

[0058] like figure 1 As shown, the system for producing the electrolytic treatment solution of the present embodiment includes: a pretreatment unit 1, the pretreatment unit 1 includes an ion exchanger 1a, a reverse osmosis device 1b and a waste water tank 1c; a brine tank 2; a mixing A tank 3; a production tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com