Method for improving water flux of composite forward osmosis membrane

A forward osmosis membrane and water flux technology, applied in the field of membrane separation, can solve the problems of large tortuosity of finger-like pore structure, lack of large finger-like pore structure, low water flux of forward osmosis membrane, etc. Quantity, reducing the phenomenon of internal concentration polarization, the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1: basement membrane soaked in 30% DMAc for 1 hr

[0056] Preparation method: Soak the basement membrane prepared in step (3) of Comparative Example 1 with a volume ratio of 30% DMAc aqueous solution for 1 hour, take it out, and fully wash it in deionized water. The rest of the steps are the same as in Comparative Example 1. Wash thoroughly with water and store in 1% sodium bisulfite solution.

[0057] Performance: With 1M NaCl and deionized water as the draw liquid and raw material liquid, the water flux of the forward osmosis membrane is 12.60±0.50LMH, the reverse salt flux is 3.21±0.50gML, and the brine ratio is 0.25g / L.

[0058] Structure: The membrane is composed of a porous support layer and a dense separation layer. The thickness of the spongy layer on the support layer decreases, but the change is not great.

Embodiment 2

[0059] Embodiment 2: The basement membrane is soaked in 50%DMF for 30min

[0060] Preparation method: Soak the base membrane prepared in step (3) of Comparative Example 1 in 50% DMF aqueous solution for 30 minutes, take it out, and wash it fully in deionized water. Rinse thoroughly with deionized water and store in 1% sodium bisulfite solution.

[0061] Performance: With 1M NaCl and deionized water as the draw solution and raw material solution, the water flux of the forward osmosis membrane is 14.90±0.61LMH, the reverse salt flux is 3.61±1.01gMH, and the brine ratio is 0.24g / L.

[0062] Structure: The membrane is composed of a porous support layer and a dense separation layer. The large finger-like pore structure in the membrane increases, and the thickness of the spongy layer in the support layer becomes smaller.

Embodiment 3

[0063] Embodiment 3: basement film soaks 1hr in 50%DMAc

[0064] Preparation method: Soak the base membrane prepared in step (3) of Comparative Example 1 in 50% DMAc aqueous solution for 1 hour, take it out, and wash it fully in deionized water. Rinse thoroughly with deionized water and store in 1% sodium bisulfite solution.

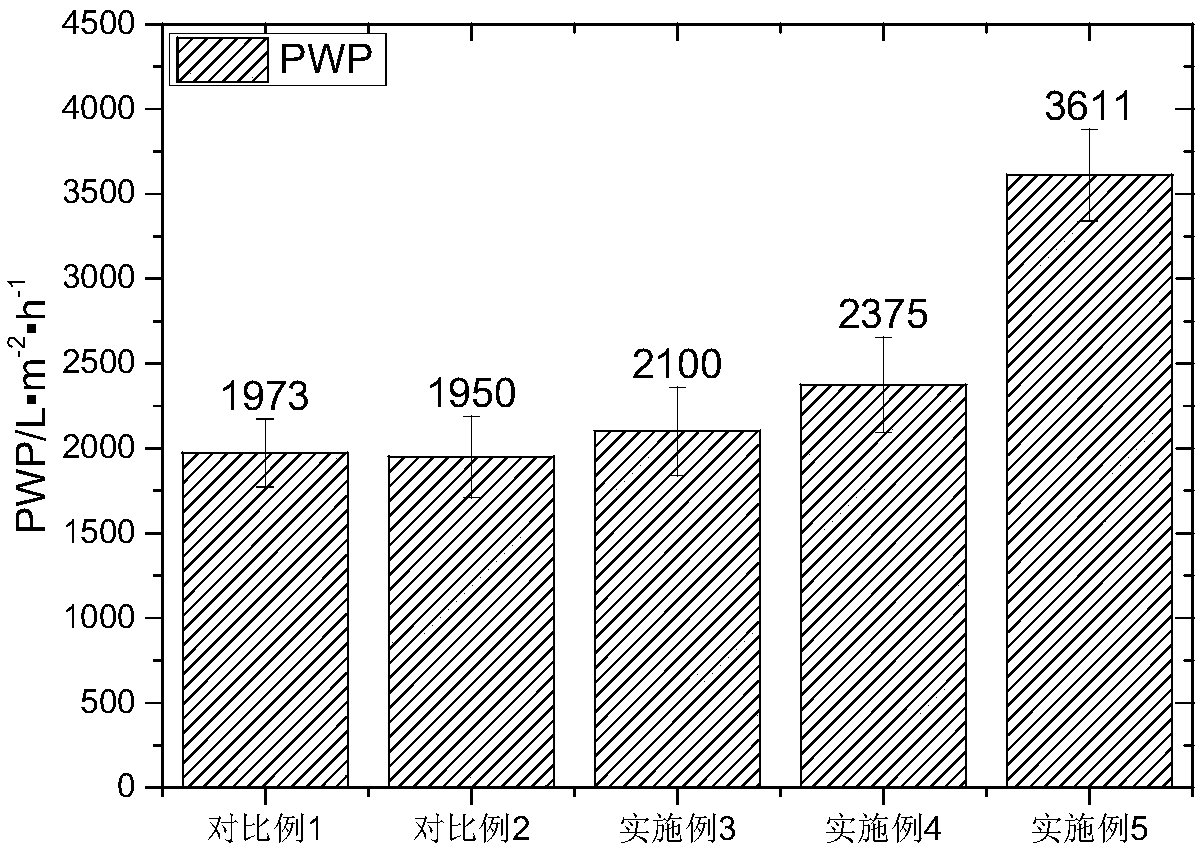

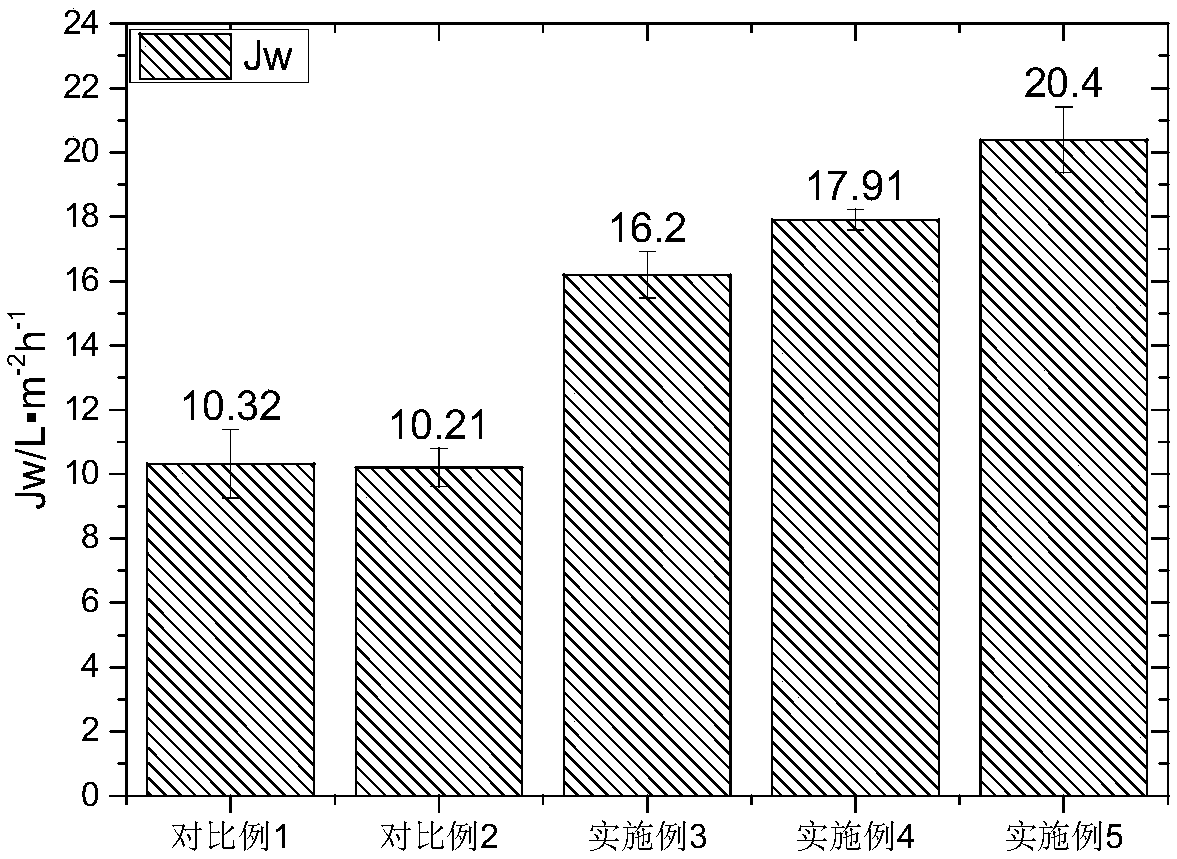

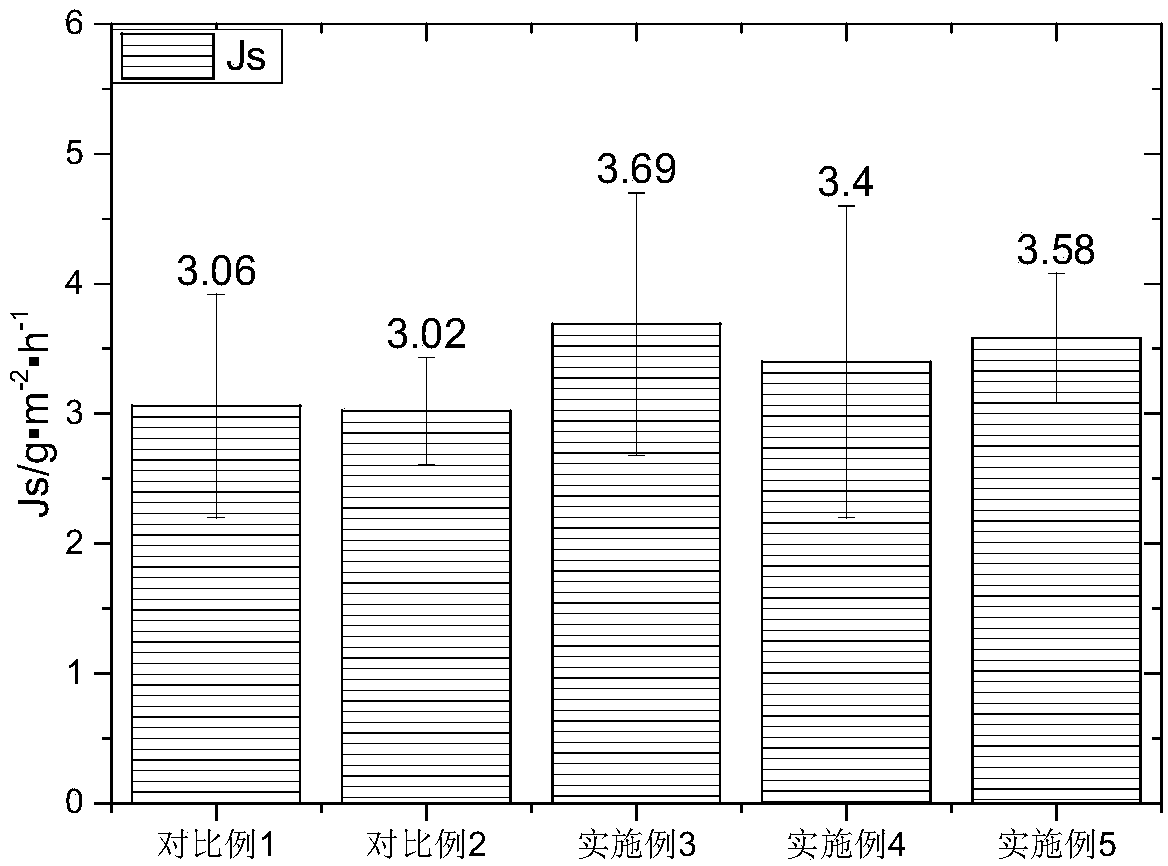

[0065] Performance: With 1M NaCl and deionized water as the draw liquid and raw material liquid, the water flux of the forward osmosis membrane is 16.20±0.72LMH, the reverse salt flux is 3.69±1.01gMH, and the brine ratio is 0.23g / L.

[0066] Structure: The membrane is composed of a porous support layer and a dense separation layer. The thickness of the spongy layer in the support layer becomes smaller, and the large finger-like pore structure in the membrane increases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com