Vertical storing feeder

A feeder and material storage technology, applied in the field of vertical storage and feeder, can solve the lagging speed of upgrading large-scale consumer goods packaging technology, increase the difficulty of material grabbing or clamping, troublesome design, production and packaging processes, etc. problem, to achieve the effect of improving feeding quality and feeding efficiency, saving horizontal space, and reducing the difficulty of grabbing or clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

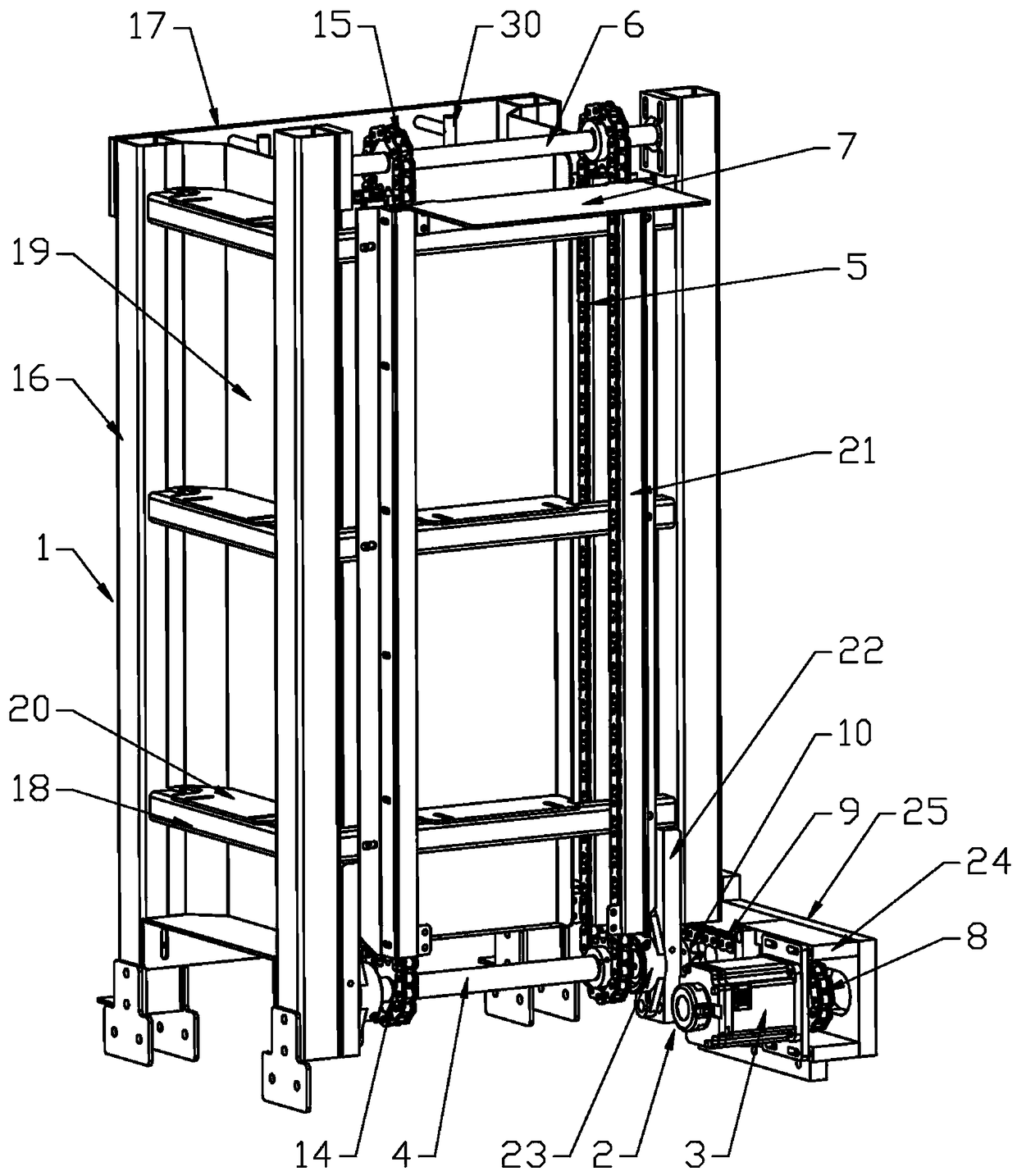

[0037] When the material that needs to be stored and fed is a small piece such as a backing plate, a partition, or a gasket, and the quality is small, select such as figure 1 Shown is a vertical stock feeder that requires only one side lift to meet stability and efficiency needs.

Embodiment 2

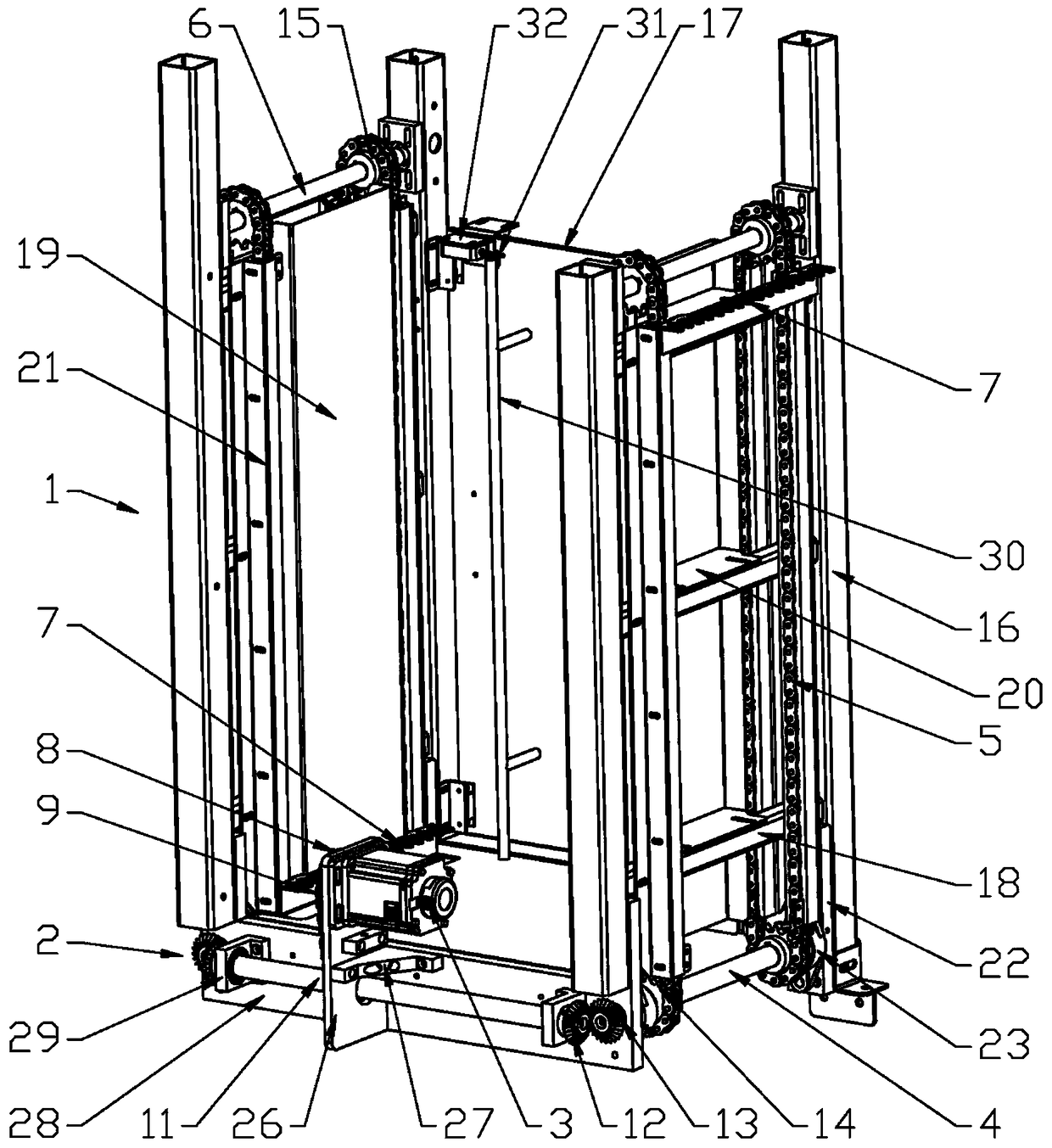

[0039] When the material that needs to be stored and fed is a large piece such as a packing box and has a large quality, select such as figure 2 Shown is a vertical stock feeder that requires double-sided lift to meet stability and efficiency needs.

[0040] In above-mentioned embodiment one, embodiment two involved figure 1 , figure 2 In general, the motor 3 is arranged at the lower part of the vertical storage feeder, and the bottom of the corresponding column 16 of the storage tank 1 is provided with a positioning mechanism to fix the vertical storage feeder at the corresponding position of the packaging system .

[0041] When the vertical storage and feeding machine of the present invention is in use, the motor 3 drives the transmission part 5 to move upward, so as to drive the material on the supporting plate 7 to move upward, and the material is sent to the top of the storage tank 1 for grabbing by the gripper or for suction. Fixture suction. When the material on o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com