Valve body of automobile hydraulic brake valve and production process thereof

A hydraulic brake valve and valve body technology, applied in the field of auto parts, can solve the problems of many variable factors, losses, and more serious piston wear, and achieve the effects of high structural strength, long service life, and stable oil pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

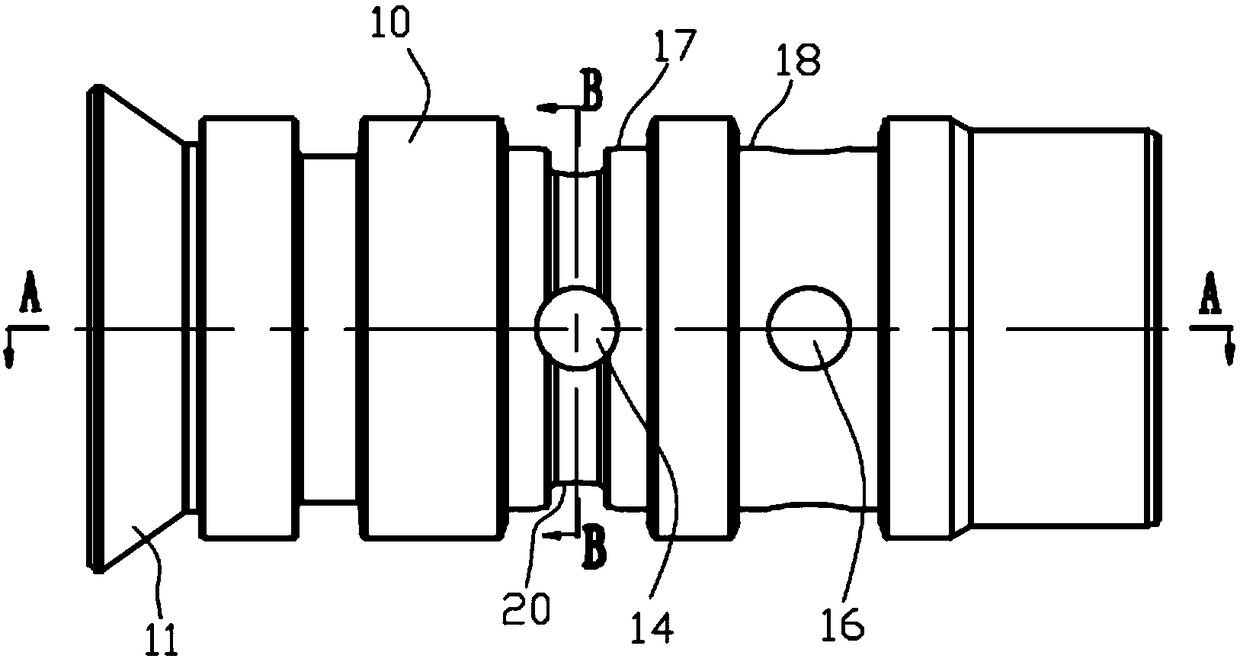

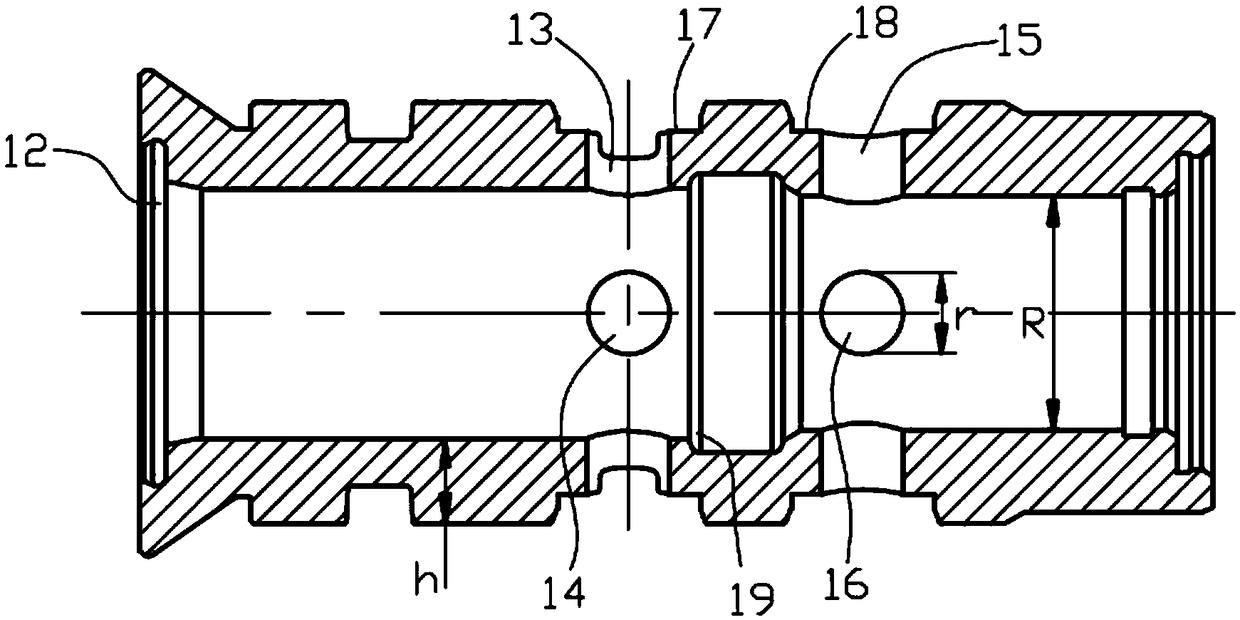

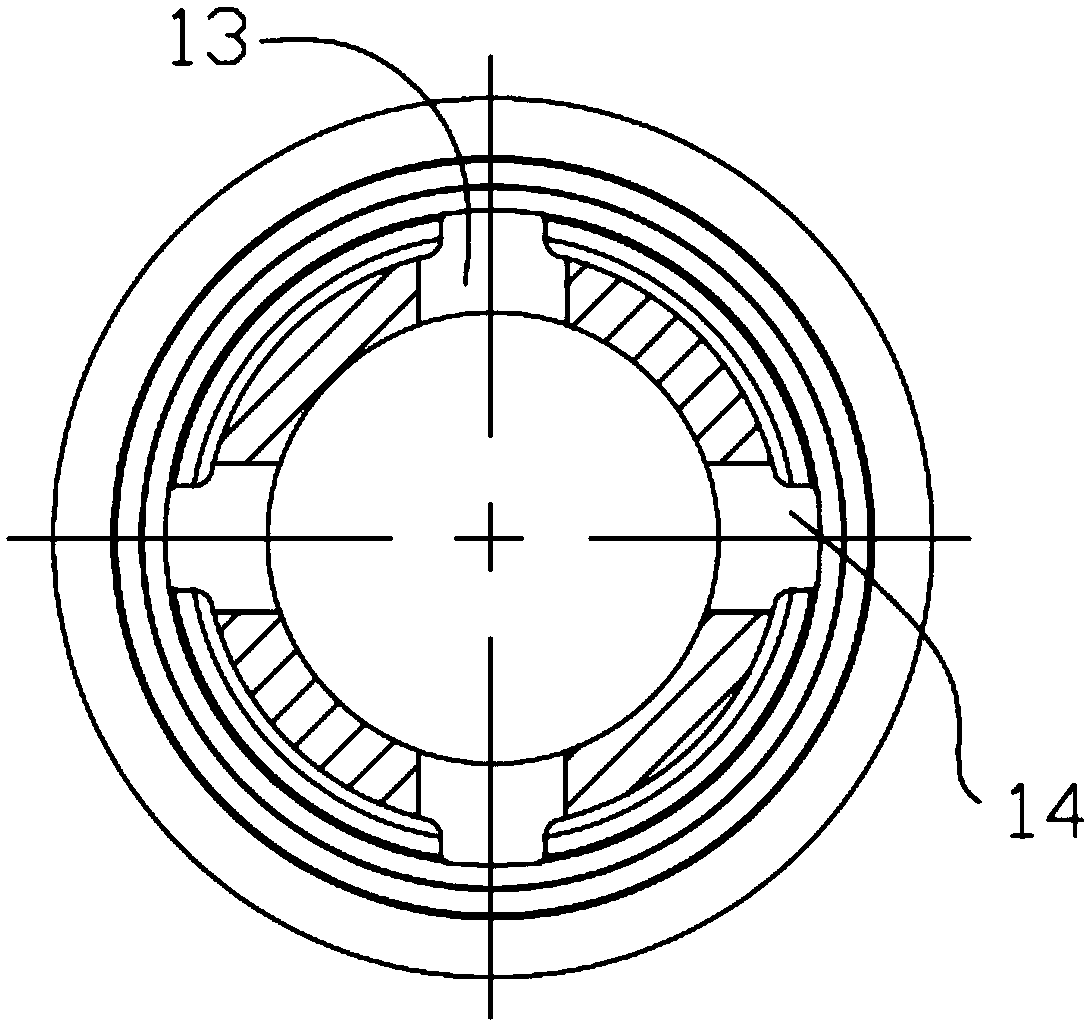

[0024] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —3: A valve body of an automobile hydraulic brake valve, the valve body 10 includes two connected ports, and the inner walls of the two ports are provided with connecting threads 12, wherein one port of the valve body 10 is set as The tapered end surface 11 is convenient to further fix the valve body 10 and prevent the port from falling off. The middle part of the valve body 10 is provided with four groups of radial through holes, which are radial through holes I13, radial through holes II14, radial through holes Hole III15 and radial through hole IV16, said radial through hole I13 and radial through hole II14 are perpendicular to and intersect each other, said radial through hole III15 and radial through hole IV16 are mutually perpendicular and intersecting, said valve body 10 There is an annular groove I19 inside. The annular groove I1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com