An electric vehicle single-controller coupling driving device and its working method

An electric vehicle, single-controller technology, applied in the control drive, electric vehicle, power unit, etc., can solve the problems of increasing the electric wheel hub motor drive control design, uneven steering torque distribution, and difficult steering angle control, etc., to achieve a reasonable Torque distribution, rapid drive response, and elimination of communication links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

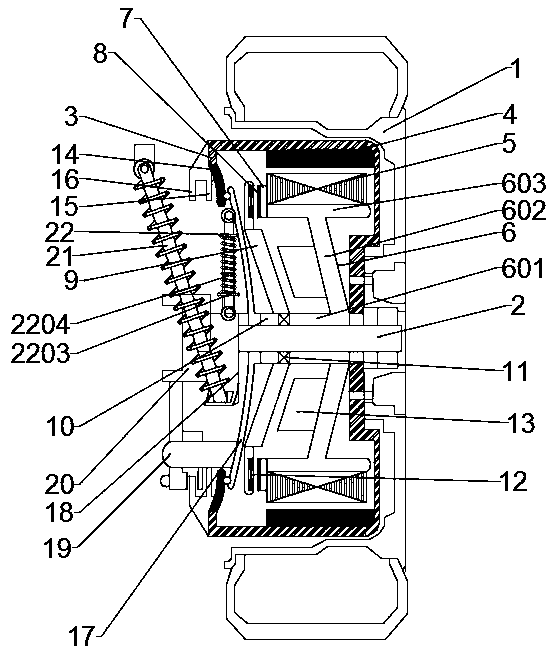

[0047] like Figure 3 to Figure 7 As shown, a hub motor driving device for an electric vehicle includes a hub motor device and a drive control system for controlling its operation. The hub motor device includes a hub 1, a main shaft 2, a rear end cover 3, a rotor 4, a stator 5 and a stator bracket 6, wherein the stator 5 is fixedly installed on the stator bracket 6, the stator bracket 6 includes a shaft sleeve 601, a middle support plate 602 and a winding stator seat 603, and the shaft sleeve 601, the middle support plate 602 and a winding stator seat 603 is integrally formed, and the shaft sleeve 601 is fixedly set on the main shaft 2, the side surface of the winding stator seat 603 is provided with a copper ring 7, and the side surface of the copper ring 7 is installed with a closed aluminum frame ring 8 , the auxiliary stator seat 9 is set on the shaft of the main shaft 2 between the rear end cover 3 and the shaft sleeve 601, and the auxiliary stator seat 9 is set on the ma...

Embodiment 3

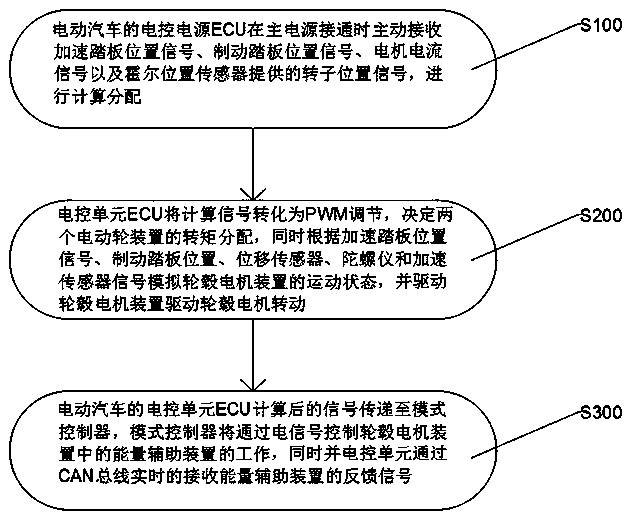

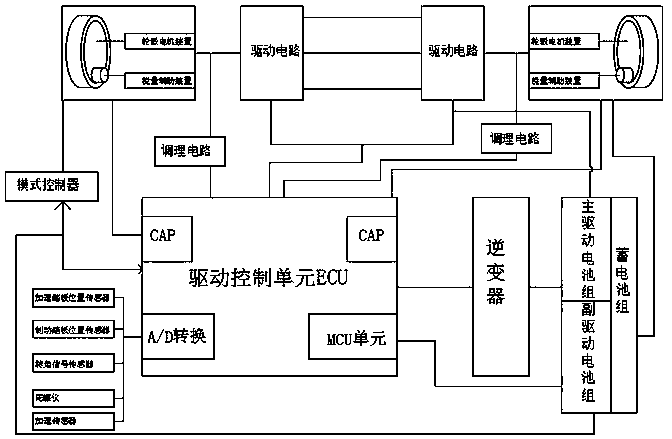

[0059] The present invention also relates to a drive control system for a single-controller coupling drive device of an electric vehicle, which includes a drive control unit ECU, a storage battery pack, an in-wheel motor device, an energy assist device installed on the in-wheel motor device, a mode controller and a sensor The group and the drive control unit ECU actively receive the A / D converted detection signal of the sensor group through the CAP interface in the power-on state, and the signal transmission mode controller after the calculation of the drive control unit ECU performs the state matching of the electric vehicle, and at the same time, the feedback The signal is transmitted to the drive control unit ECU, and the drive control unit ECU drives the inverter with the controller to drive the work of the hub motor device according to the feedback signal, and at the same time the independent MCU unit in the mode controller will control the work of the energy assist device,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com