Hot-melt plug welding positioning press and working method thereof

A press and hot-melt technology, which is applied to other household appliances, household appliances, applications, etc., can solve problems such as hidden dangers in pipe network operation, weak welding, poor plugging quality, etc., and reduce welding defects and plug cracking Reduce and improve the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with embodiment, but is not limited to the content on the description.

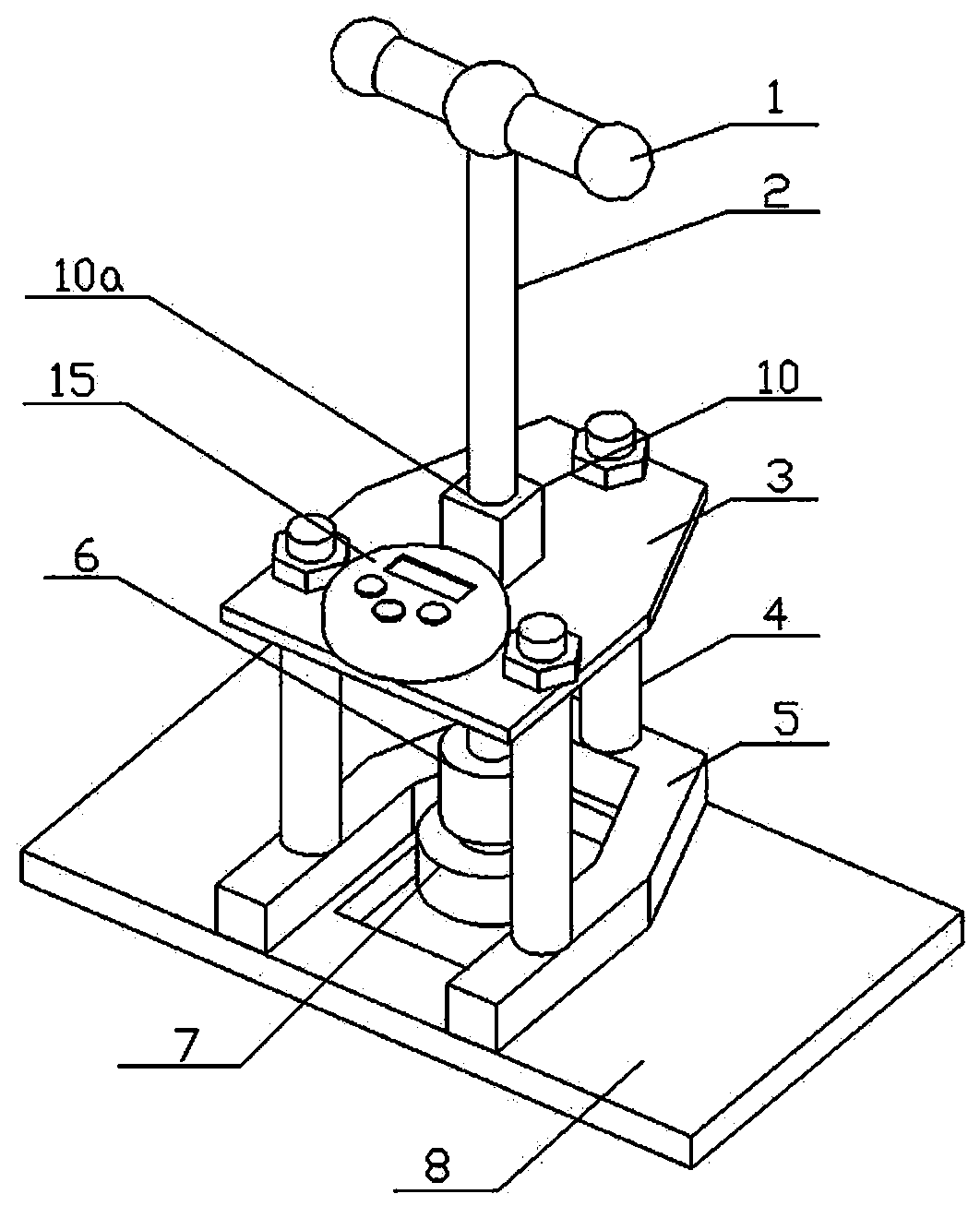

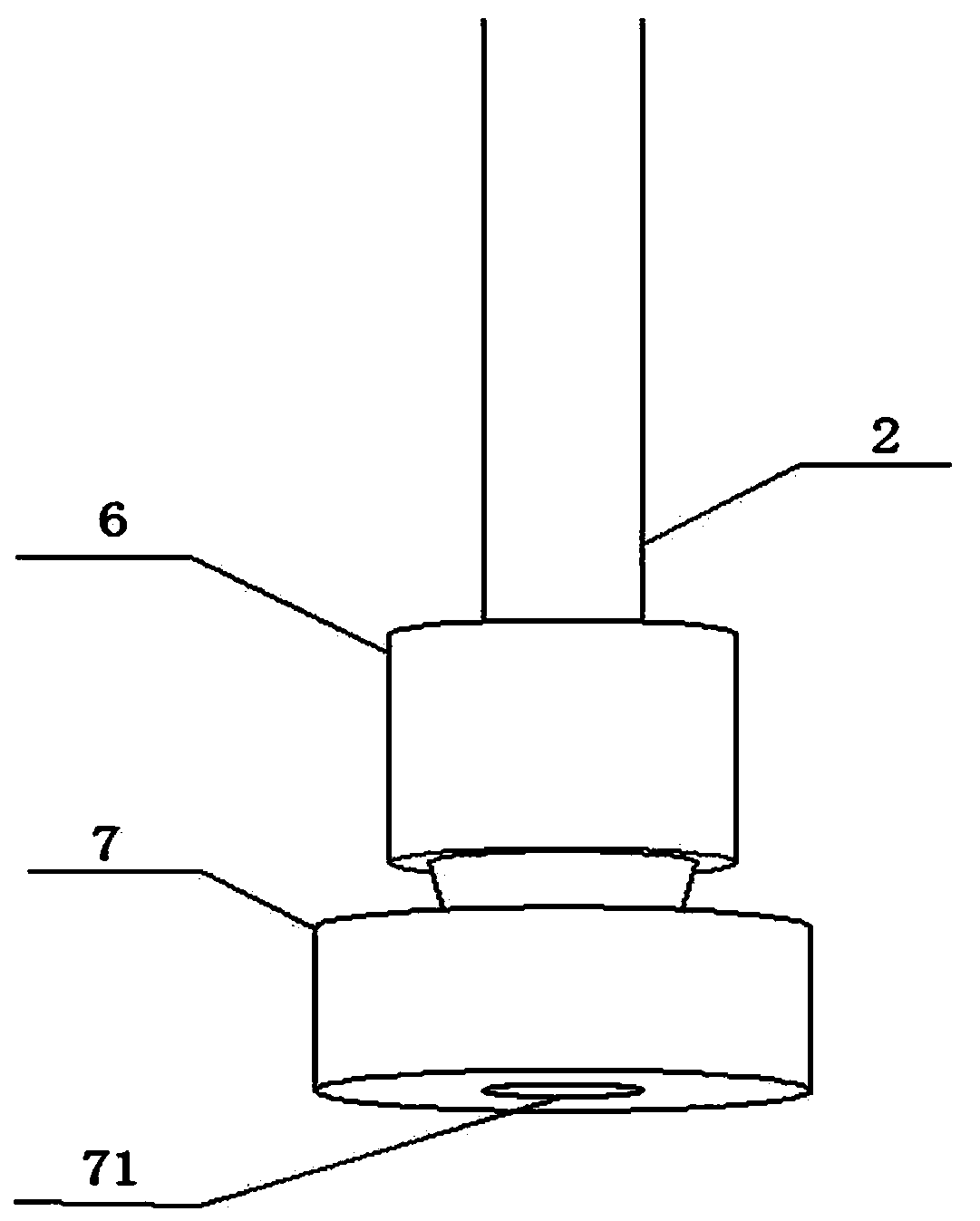

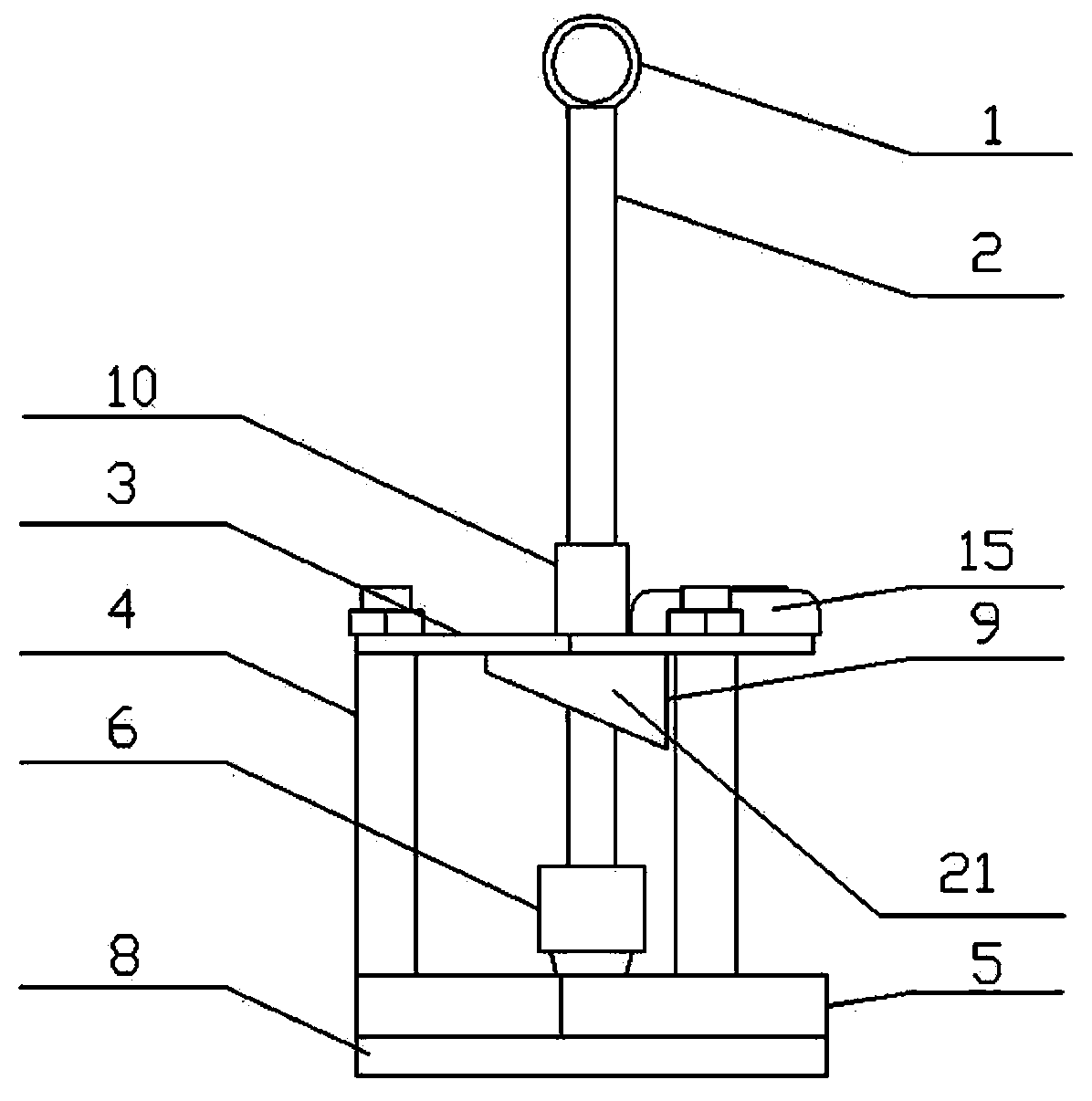

[0031] Such as figure 1 , figure 2 and image 3 As shown, the present invention relates to a hot melt plug welding positioning press, which includes a handle 1, a pressure rod 2, a top plate 3, a support member 4, a positioning clamp 5, a positioning body 6, a mold 7, a bottom plate 8 and a fixing pin 9 , the pressure rod 2 vertically passes through the top plate 3, the top and bottom ends of the pressure rod 2 are fixedly connected with the handle 1 and the positioning body 6 respectively, and the bottom end of the positioning body 6 is detachably connected with the mold 7, preferably screwed here.

[0032] The support member 4 is preferably three cylinders in terms of stability and economy. The top and bottom ends of the support member 4 are fixedly connected with the top plate 3 and the positioning clip 5 respectively to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com