High-pressure water gun chiseling construction equipment and method

A high-pressure water gun and construction equipment technology, which is used in manufacturing tools, ceramic molding machines, ceramic molding linings, etc., can solve the problem of frequent changes in force, unstable distance between the high-pressure water gun and the surface to be chiseled, and inability to determine if the retarder is rinsed clean. and other problems, to achieve the effect of good chisel hair effect and stable chisel hair quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

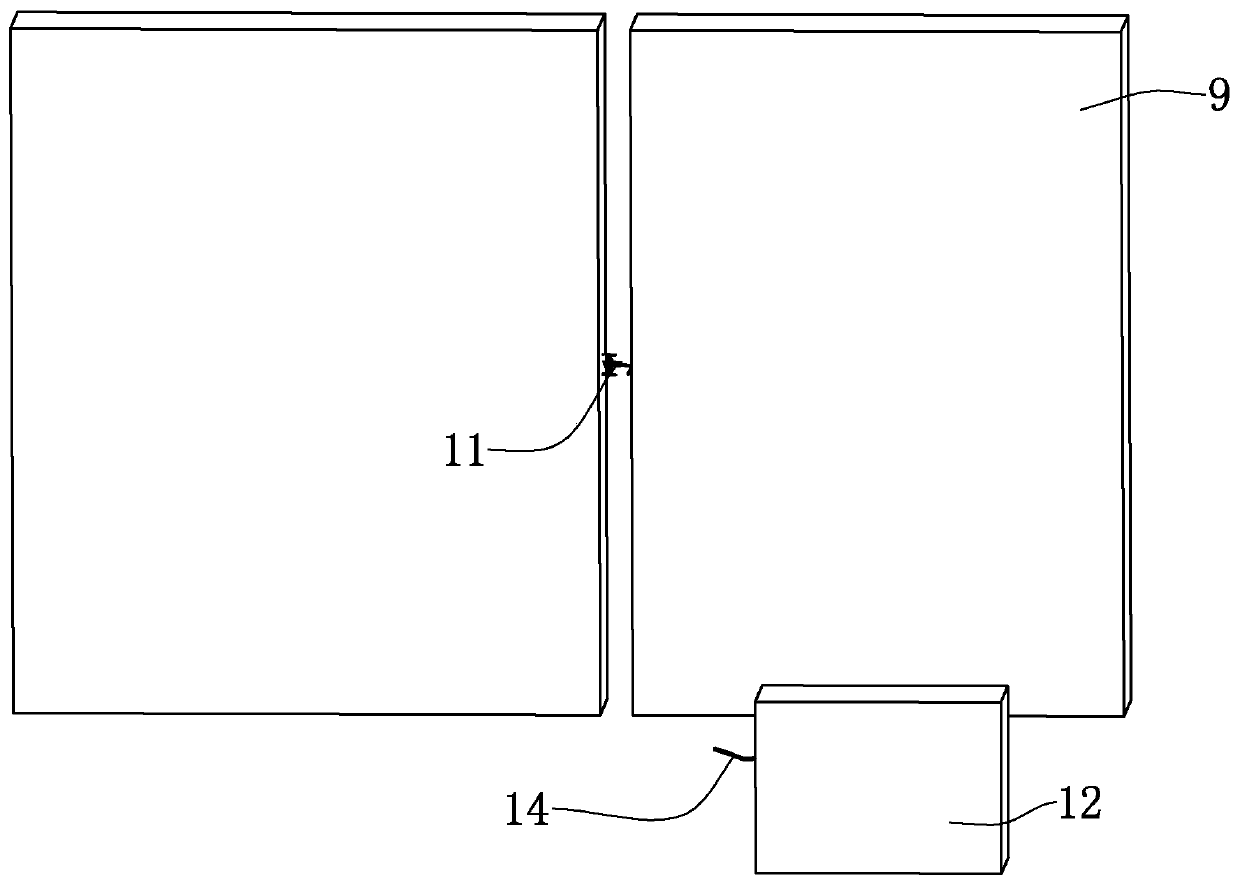

[0046] A high-pressure water gun chiseling construction equipment, such as figure 1 As shown, a pressure pump 12 is included, and the pressure pump 12 is communicated with a pipeline 14 for conveying high-pressure water, and the end of the pipeline 14 away from the pressure pump 12 is communicated with a water spray gun 11 .

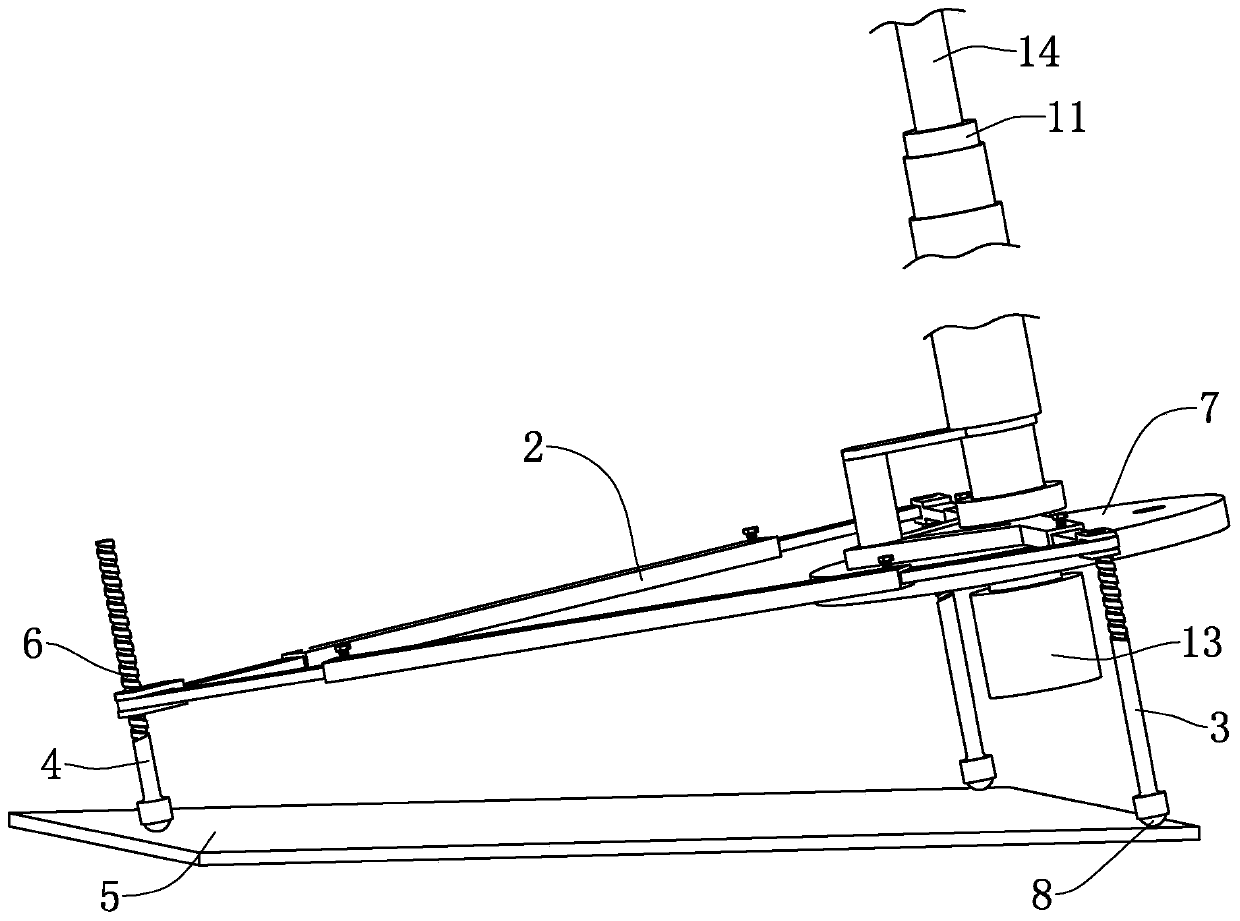

[0047] Such as figure 2 As shown, the end of the water spray gun 11 away from the pipeline 14 is provided with a spray head 13 . The outside of the water spray gun 11 is provided with a support frame 2 that rotates around the centerline of the water spray gun 11 .

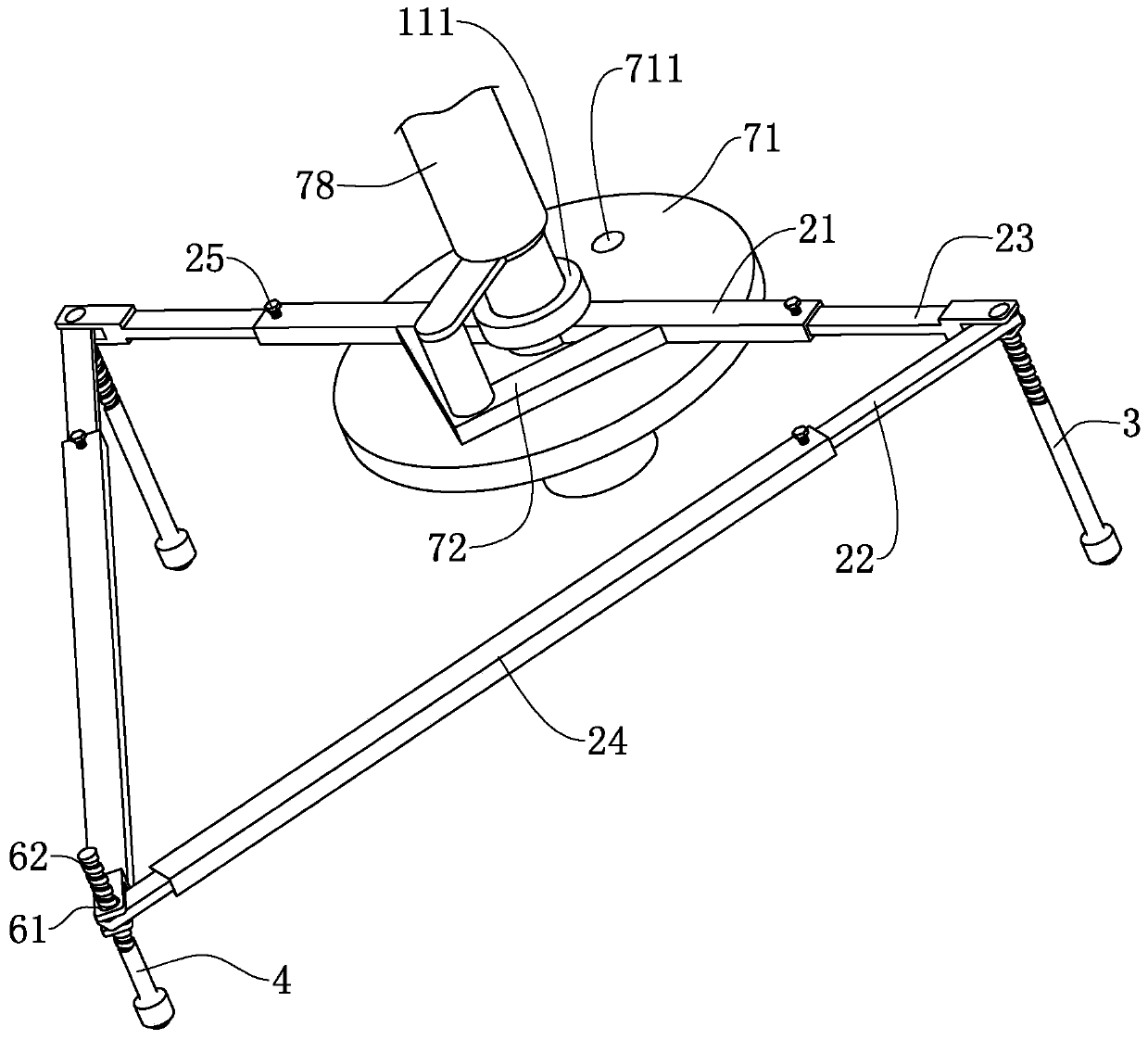

[0048] Such as image 3 As shown, the support frame 2 includes a connecting rod 21 that is in contact with the side of the water spray gun 11. The end face of the connecting rod 21 toward the water spray gun 11 is in contact with the side of the water spray gun 11, and the side of the connecting rod 21 away from the nozzle 13 is in contact with the water spray. The limit ring 111 that gun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com