Dry treatment method of bauxite tailings

A technology of dry processing and bauxite, which is applied in the direction of chemical instruments and methods, wet separation, solid separation, etc., can solve the problem that the biological reclamation of backfill goaf is not very beneficial, has not been applied and promoted, and the production cost is high problems, to achieve obvious safety and environmental protection effects, improve the comprehensive utilization of resources, and improve the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

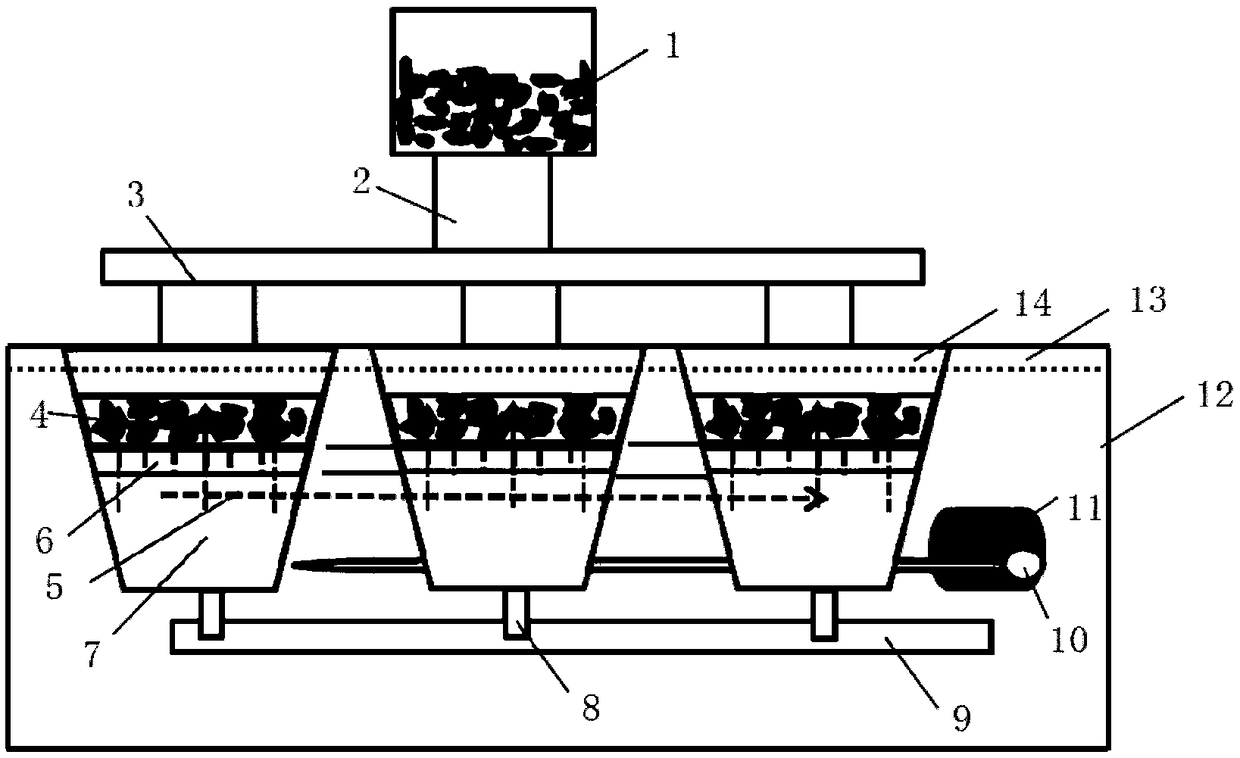

[0039] The present invention will be described in detail below in conjunction with examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For convenience of description,

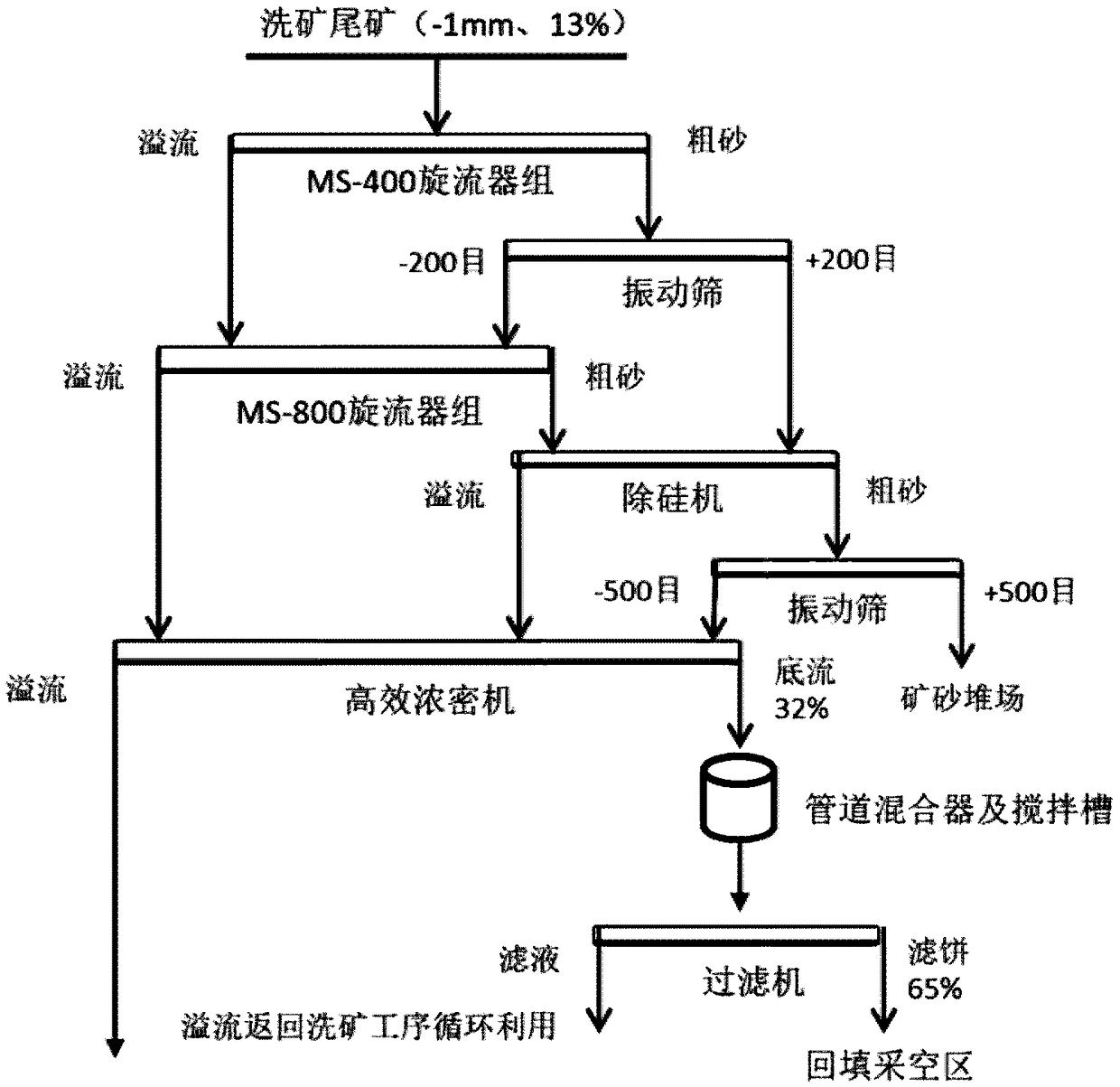

[0040] In this embodiment, the pipeline and the slurry pump are used to first introduce the washing tailings (-1mm, solid content of 13%) into the MS-400 cyclone group, the coarse sand enters the 1# vibrating screen, and the MS-400 cyclone The group overflow and vibrating screen 1 undersize slurry are introduced into the MS-800 cyclone group, and the coarse sand produced by the MS-800 cyclone group and the 1# vibrating screen onscreen enter the silicon removal machine, and the silicon removal machine produces The coarse sand is dehydrated by the 2# vibrating screen and then transferred to the storage yard through the belt conveyor. The overflow of the MS-800 cyclone group and the silicon rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com