A composite absorbent coil containing a foaming material

A technology of foaming materials and roll materials, which is applied in the direction of absorbent pads, medical science, bandages, etc., and can solve problems affecting the air permeability of absorbent products, core layer breakage, and liquid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

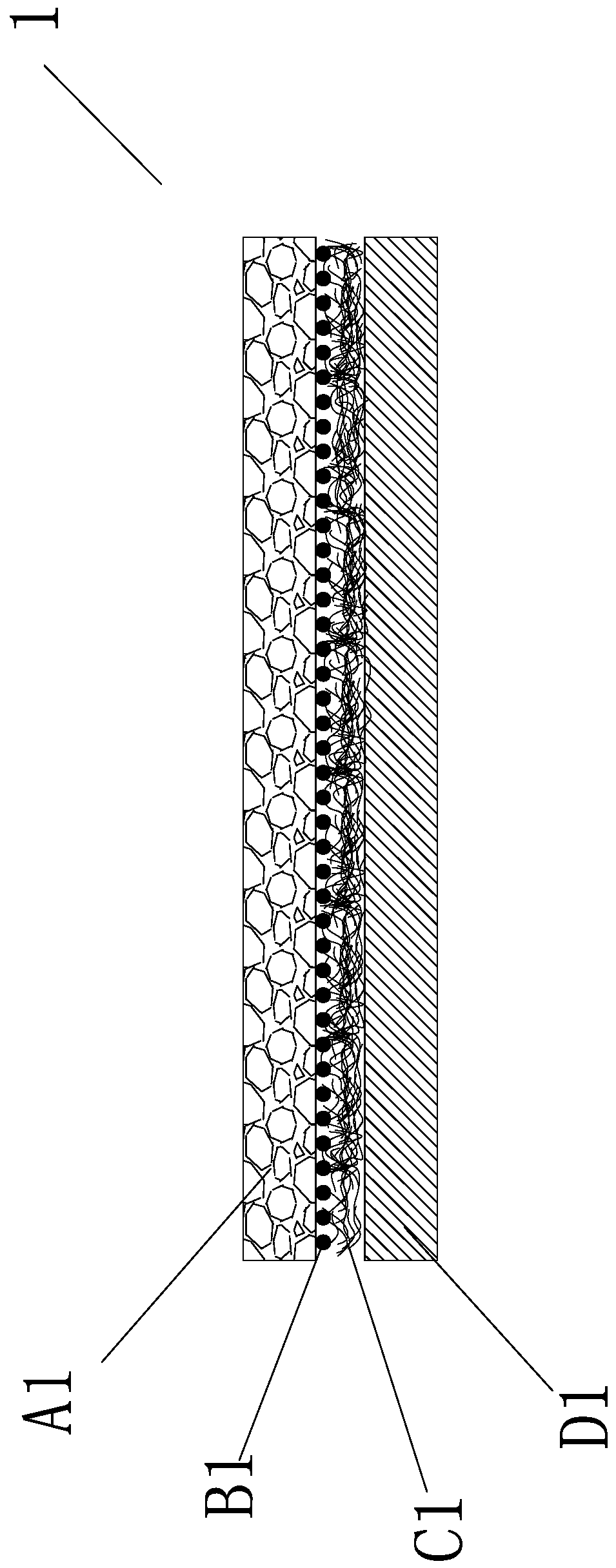

Embodiment 1

[0033] Such as figure 1 As shown, a composite absorbent roll material 1 containing foam material, said composite absorbent roll material 1 comprises surface foam material layer A1, super absorbent resin layer B1, fluff pulp layer C1 and The bottom surface layer D1, wherein: the surface foam material layer A1 is an open-cell melamine foam material with a thickness of 3mm and a porosity of 90%; the superabsorbent resin layer B1 is only made of superabsorbent resin; the bottom surface layer D1 is Dust-free paper. The fluff pulp layer C1 is located on the lower surface of the superabsorbent resin layer B1. The surface foam material layer A1, the superabsorbent resin layer B, the fluff pulp layer C1 and the bottom surface layer D1 are glued together in pairs to form a composite absorbent coil 1 .

[0034] Penetration Testing

[0035] Measuring instruments: balance, standard draining funnel, standard briquetting (Φ100 mm, mass 1.2±0.002kg) and ruler.

[0036] Test solution: 0.9%...

Embodiment 2

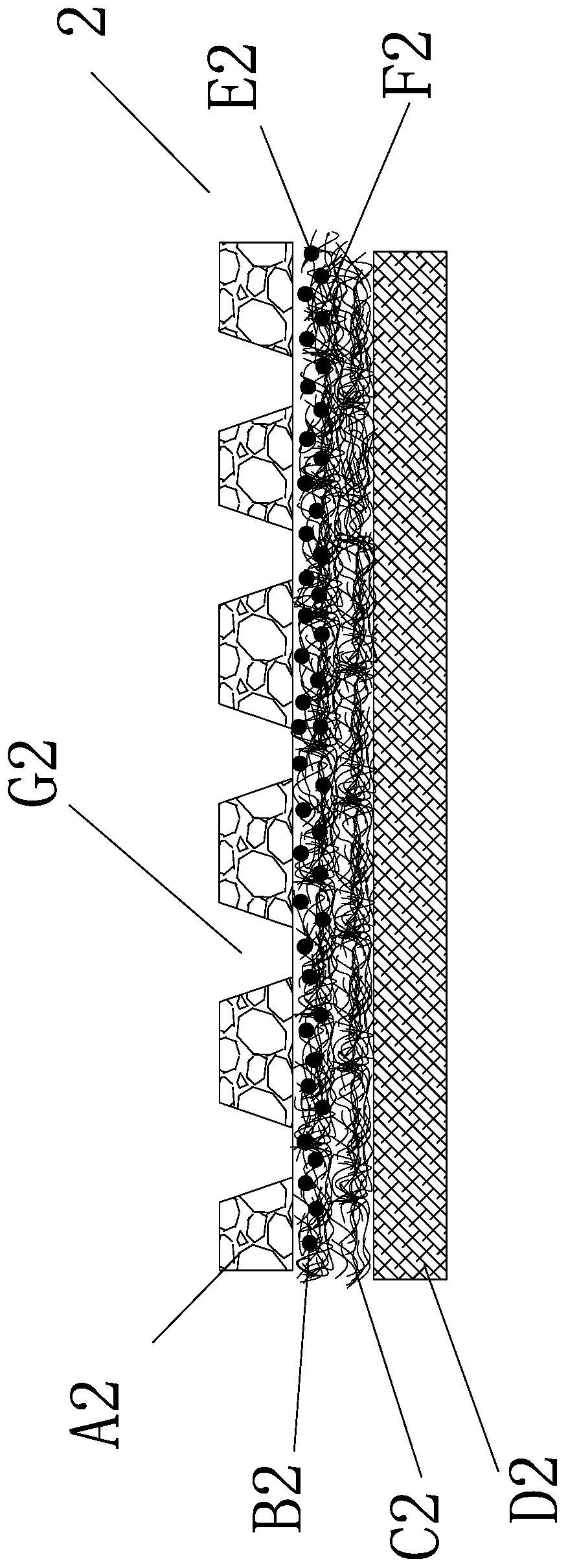

[0059] Such as figure 2 As shown, a composite absorbent roll material 2 containing foam material, said composite absorbent roll material 2 comprises surface foam material layer A2, super absorbent resin layer B2, fluff pulp layer C2 and The bottom surface layer D2, wherein: the surface foam material layer A2 is an open-celled soft polyurethane foam material with a thickness of 4 mm and a porosity of 95%, and has a funnel-shaped opening G2 running through the surface foam material layer A2; The superabsorbent resin layer B2 is composed of a superabsorbent resin E2 and a fluffy nonwoven fabric F2 for fixing the superabsorbent resin; the bottom surface layer D2 is a nonwoven fabric. The fluff pulp layer C2 is located on the lower surface of the superabsorbent resin layer B2. The surface foam material layer A2, the superabsorbent resin layer B2, the fluff pulp layer C2 and the bottom surface layer D2 are bonded together by thermocompression to form a composite absorbent roll 2. ...

Embodiment 3

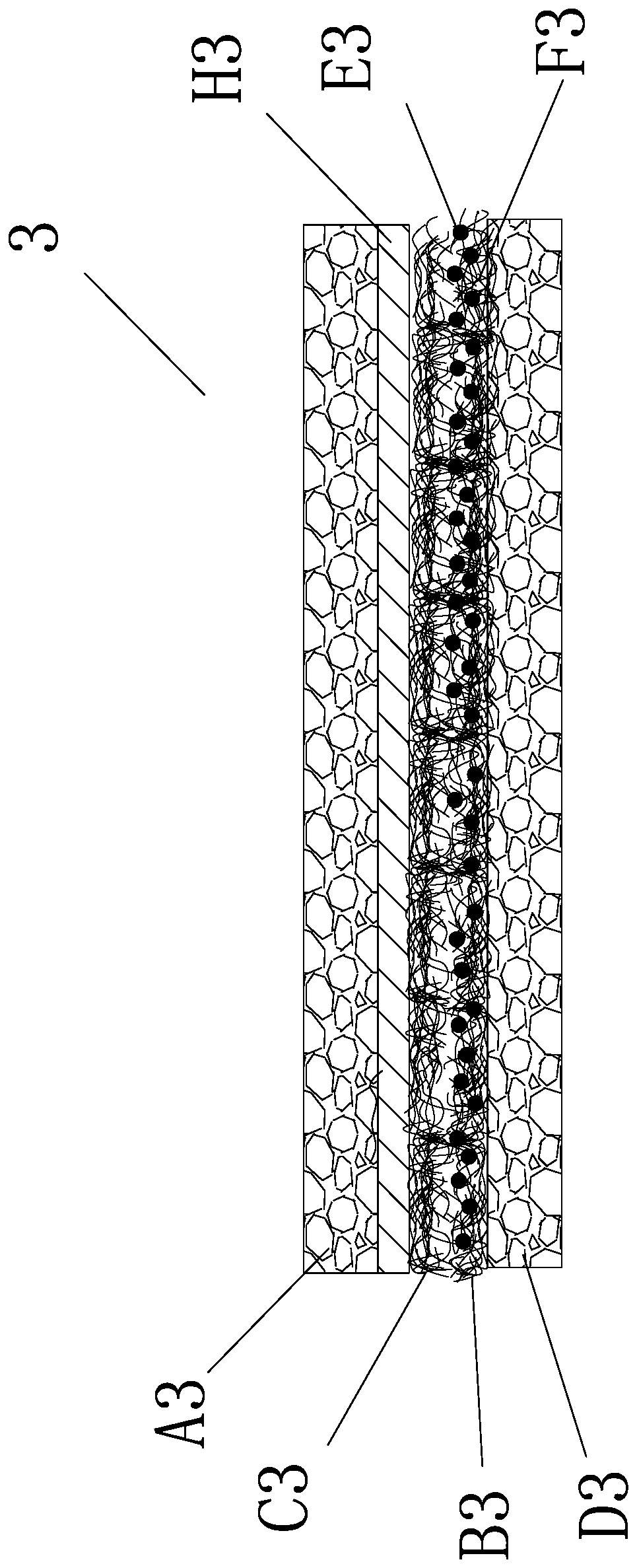

[0064] Such as image 3 As shown, a composite absorbent roll material 3 containing foam material, said composite absorbent roll material 3 comprises surface foam material layer A3, fluff pulp layer C3, super absorbent resin layer B3 and Bottom surface layer D3, and has a flow-guiding layer H3 between surface foaming material layer A3 and fluff pulp layer C3, wherein: surface foaming material layer A3 is open-cell melamine foaming material, and thickness is 5mm, and opening rate is 95%; the superabsorbent resin layer B3 is composed of superabsorbent resin E3 and the material fluff pulp F3 for fixing the superabsorbent resin; the bottom surface layer C3 is melamine foam material. The fluff pulp layer C3 is located on the upper surface of the superabsorbent resin layer B3. The surface foam material layer A3, the flow guide layer H3, the fluff pulp layer C3, the superabsorbent resin layer B3, and the bottom surface layer C3 are bonded together by thermocompression to form a compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com