Control of permanent magnet motors and generators

A technology of permanent magnet motor and permanent magnet generator, which is applied in the direction of AC motor control, electronic commutation motor control, single motor speed/torque control, etc., and can solve the problems of high cost and complexity of electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

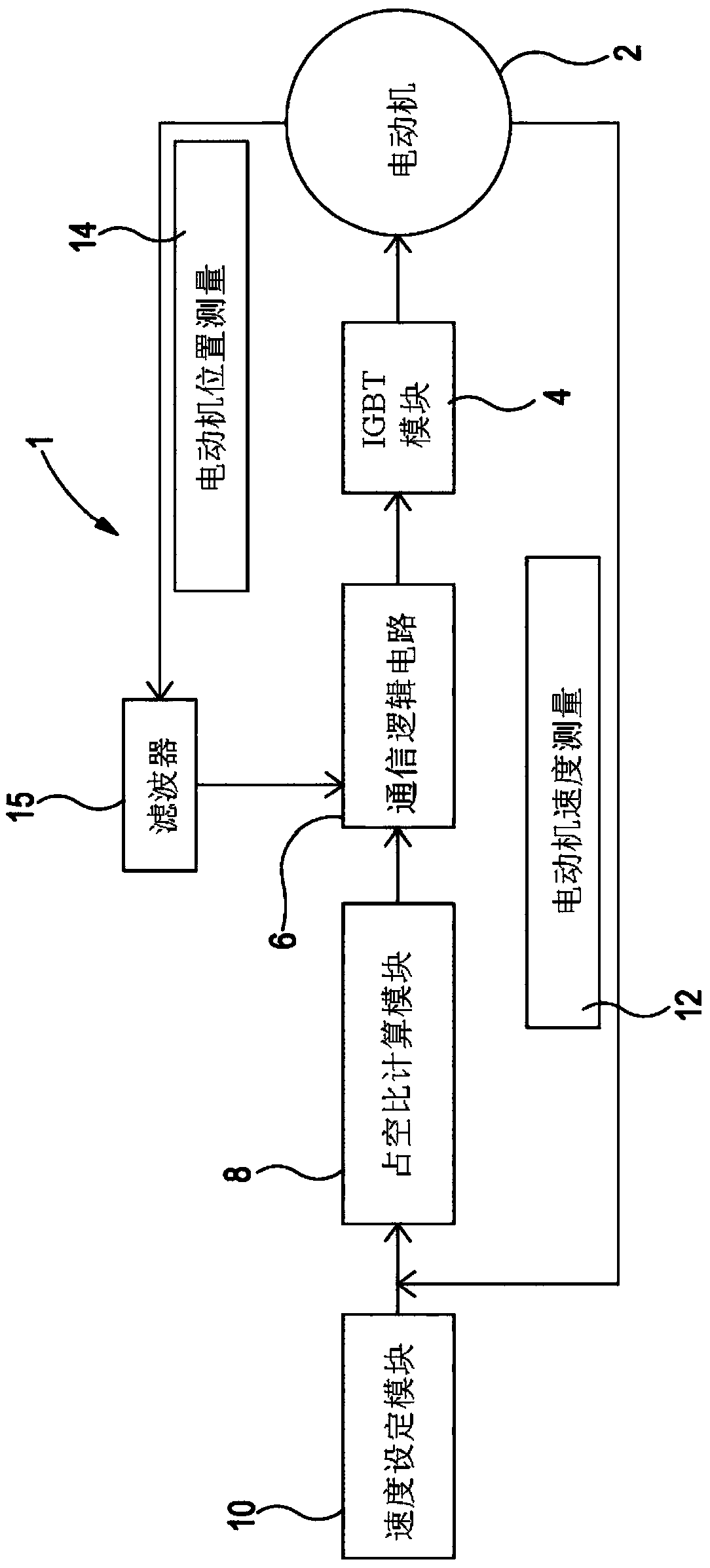

[0042] refer to figure 1 , shows a schematic diagram of a brushless DC motor controller 1, which includes a brushless DC motor 2, an integrated gate bipolar transistor (IGBT) module 4, a commutation logic circuit 6, a duty ratio calculation module 8, a speed setting Module 10 and feedback loops for motor speed measurement 12 and for motor position measurement 14 . The feedback loop for motor position measurement 14 includes a filter 15 .

[0043] The desired motor speed 10 is compared to the rotor speed measurement 12, which is used to perform a duty cycle calculation 8 to determine the required motor current. The commutation logic 6 determines which stator windings require current based on filtered motor position measurements 14 , which in this case come from measurements of the motor emf. The calculated duty cycle and commutation signals are fed into the motor controller 4 which ensures that the correct current flows through the correct windings of the motor 2 . The funct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com