Physically simulated gas injection-production flow control system of gas storage

A technology of control system and physical simulation, applied in the direction of flow control, control/regulation system, flow control using electrical devices, etc. It can achieve the effect of optimizing construction and injection-production operation plan, realizing data monitoring and operation automation, and complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings. Here, the exemplary embodiments of the present invention and their descriptions are used to explain the present invention, but not to limit the present invention.

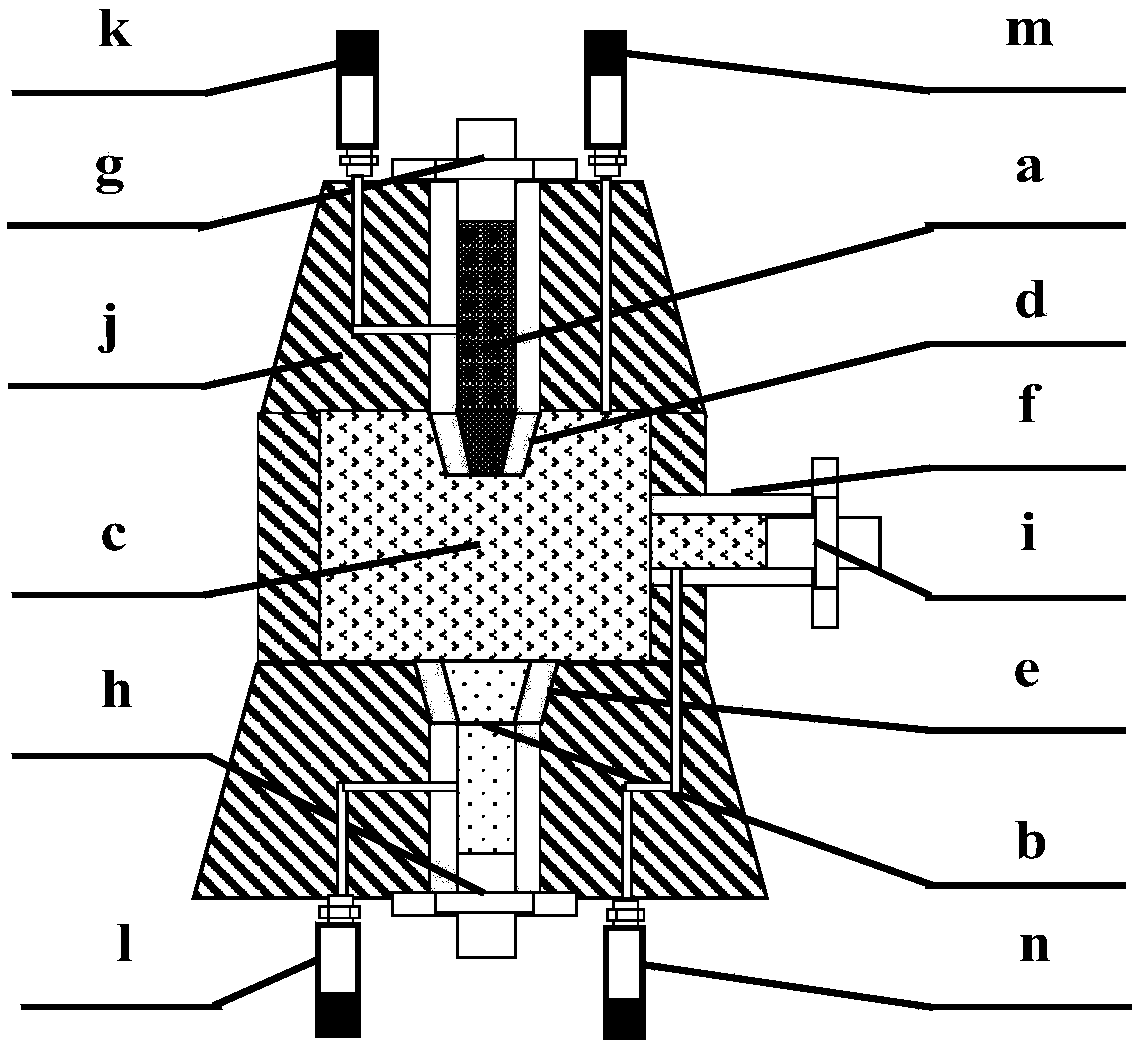

[0024] Please refer to figure 1As shown, the gas storage physical simulation injection-production gas flow control system provided by the present invention specifically includes: injection-production control devices 1, 2, gas booster devices 3, 4, gas cylinder devices 5, 6, and gas flow monitoring devices 7, 8, gas storage core model 9 and control analysis device 10; the gas injection and production control devices 1 and 2 are connected to the gas storage core model 9, and the gas injection and production control devices 1 and 2 include a high-pressure chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com