Method for manufacturing piezoresistive sensor by controlling three-dimensional conductive gauze structure

A technology of piezoresistive sensor and conductive yarn, applied in the direction of instrument, measuring force, measuring device, etc., can solve the problems of low cost and achieve the effect of wide detection range and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

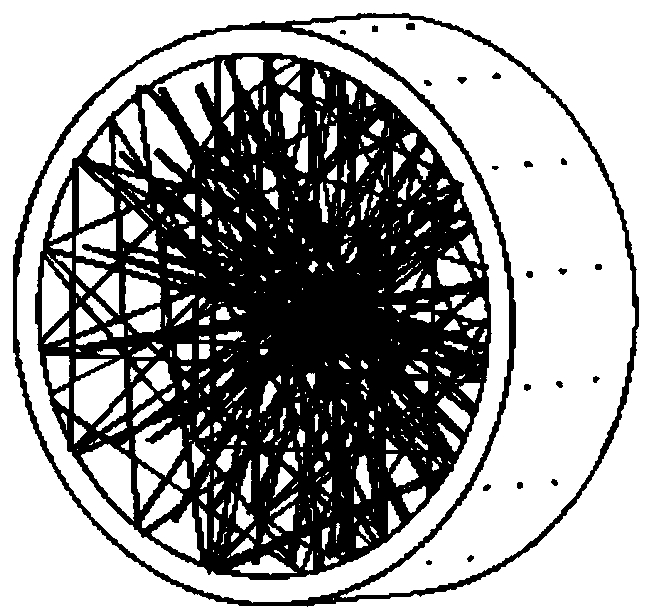

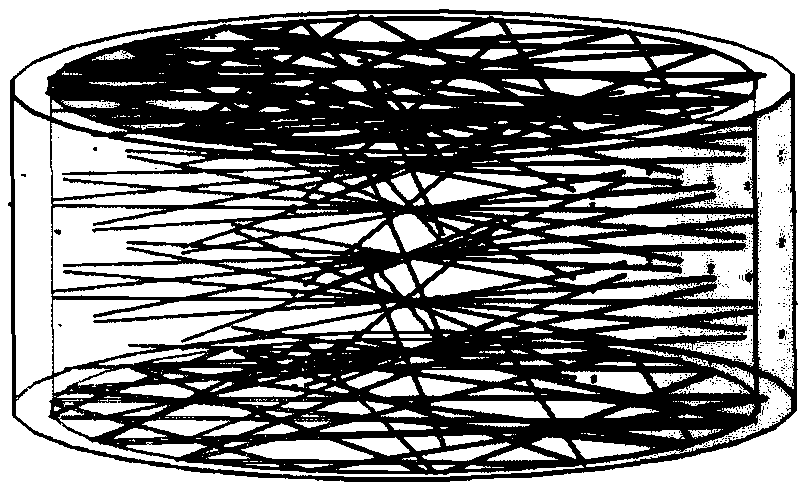

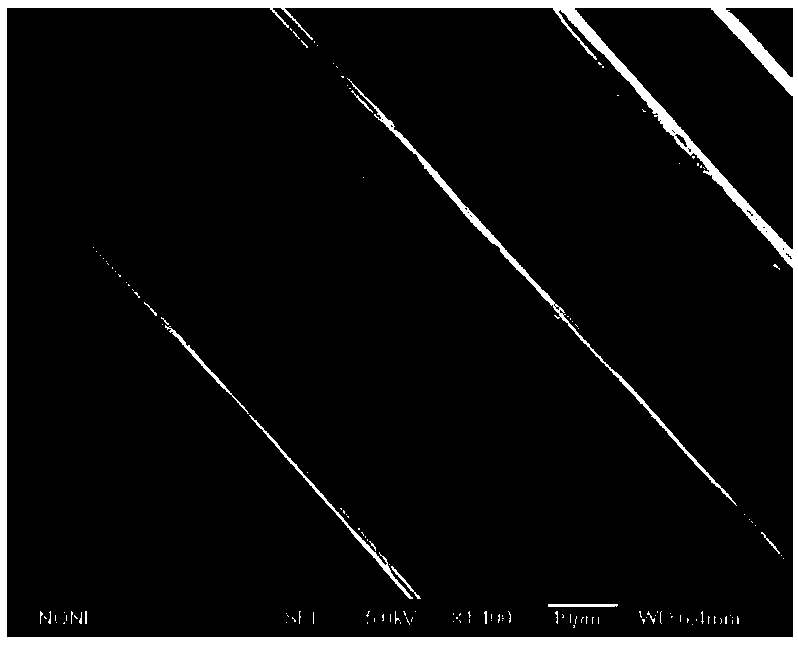

Embodiment 1

[0055] Polyurethane elastic fibers with a length of 1m are evenly interspersed and wound on the porous polyethylene ring from top to bottom in a "Z" shape to construct a three-dimensional gauze structure. The diameter of the ring is 32mm and the height is 11.5mm. The 4*20 matrix array is evenly arranged. To configure carbon black suspension, add 0.2448g superconducting carbon black BP2000 (CB) to 800mL with a concentration of 0.613mg.mL -1 In the CNC suspension, the mixture was ultrasonically treated for 30 minutes with the stirrer rotating at 200r / min and the power at 1200w, and finally a completely suspended negatively charged CB@CNC suspension was obtained. Add 0.2448g CB to 800mL with a concentration of 0.613mg.mL -1 In the CS suspension, the mixture was sonicated for 30 minutes with the stirrer rotating at 200r / min and the power at 1200w, and finally a completely suspended positively charged CB@CS suspension was obtained. The three-dimensional gauze structure was then w...

Embodiment 2

[0057] Polyurethane elastic fibers with a length of 1m are evenly interspersed and wound on the porous polyethylene ring from top to bottom in a "Z" shape to construct a three-dimensional gauze structure. The diameter of the ring is 32mm and the height is 11.5mm. The 4*20 matrix array is evenly arranged. To configure carbon black suspension, add 0.2448g superconducting carbon black BP2000 (CB) to 800mL with a concentration of 0.613mg.mL -1 In the CNC suspension, the mixture was ultrasonically treated for 30 minutes with the stirrer rotating at 200r / min and the power at 1200w, and finally a completely suspended negatively charged CB@CNC suspension was obtained. Add 0.2448g CB to 800mL with a concentration of 0.613mg.mL -1 In the CS suspension, the mixture was sonicated for 30 minutes with the stirrer rotating at 200r / min and the power at 1200w, and finally a completely suspended positively charged CB@CS suspension was obtained. The three-dimensional gauze structure was then w...

Embodiment 3

[0059] Polyurethane elastic fibers with a length of 9m are evenly interspersed and wound on the porous polyethylene ring from top to bottom in a "Z" shape to construct a three-dimensional gauze structure. The diameter of the ring is 32mm and the height is 11.5mm. The 4*20 matrix array is evenly arranged. To configure carbon black suspension, add 0.2448g superconducting carbon black BP2000 (CB) to 800mL with a concentration of 0.613mg.mL -1 In the CNC suspension, the mixture was ultrasonically treated for 30 minutes with the stirrer rotating at 200r / min and the power at 1200w, and finally a completely suspended negatively charged CB@CNC suspension was obtained. Add 0.2448g CB to 800mL with a concentration of 0.613mg.mL -1 In the CS suspension, the mixture was sonicated for 30 minutes with the stirrer rotating at 200r / min and the power at 1200w, and finally a completely suspended positively charged CB@CS suspension was obtained. The three-dimensional gauze structure was then w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com