Heat exchange tube and air conditioner

A technology of heat exchange tubes and tube bodies, which is applied in the direction of heat sinks, tubular components, heat exchange equipment, etc., and can solve problems such as flooding on the surface of liquid refrigerants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

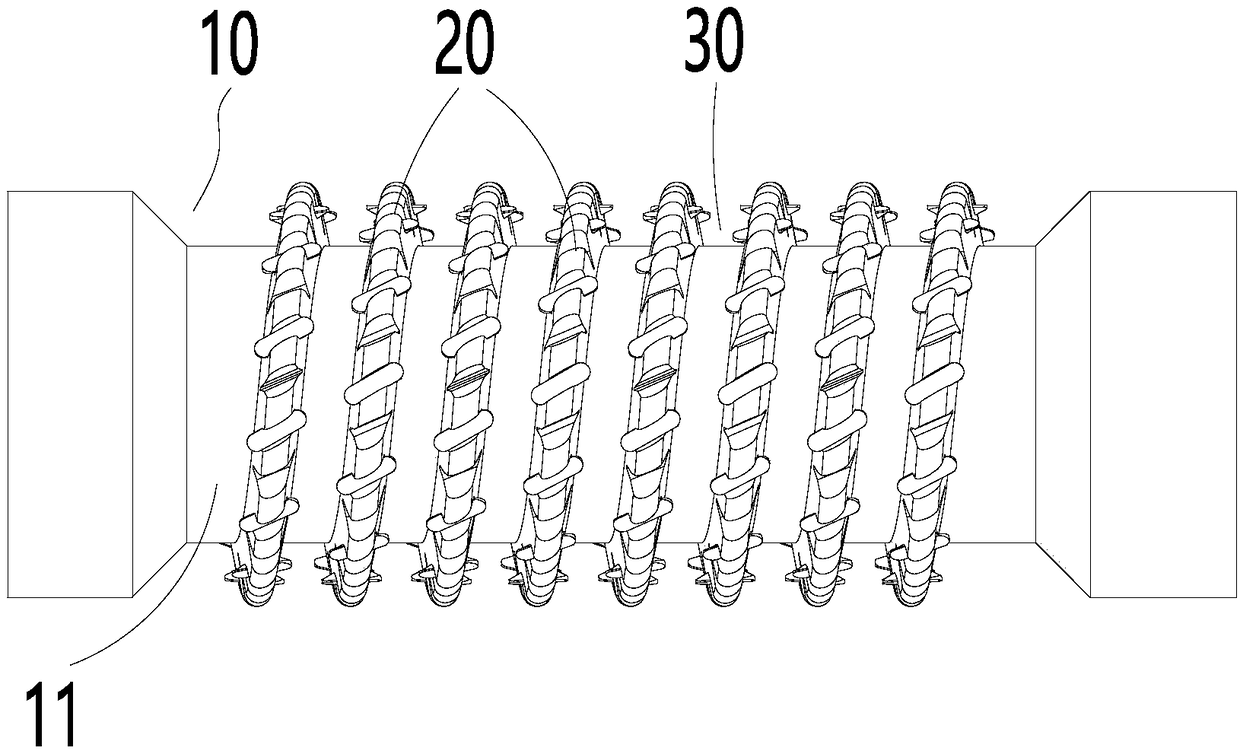

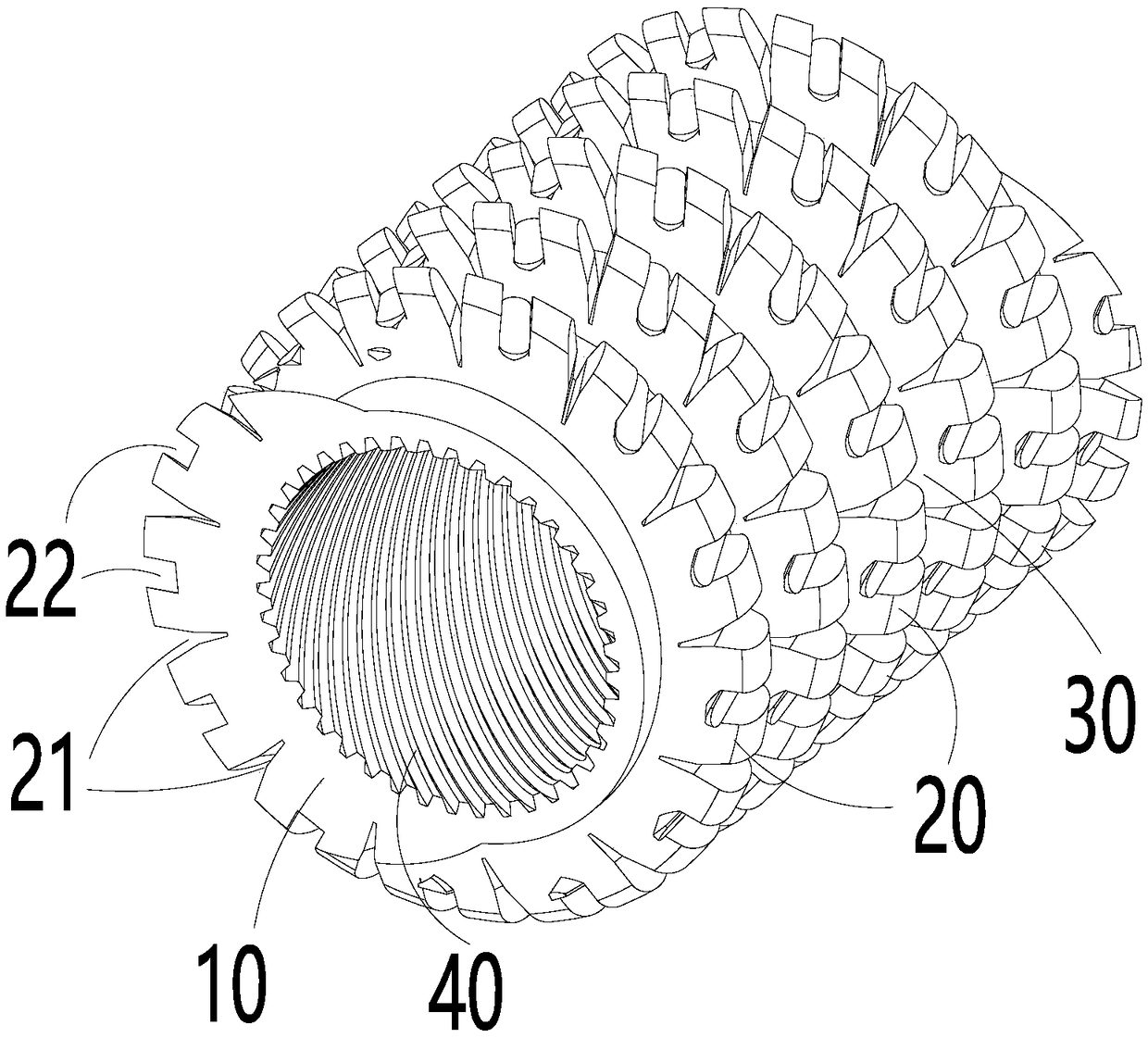

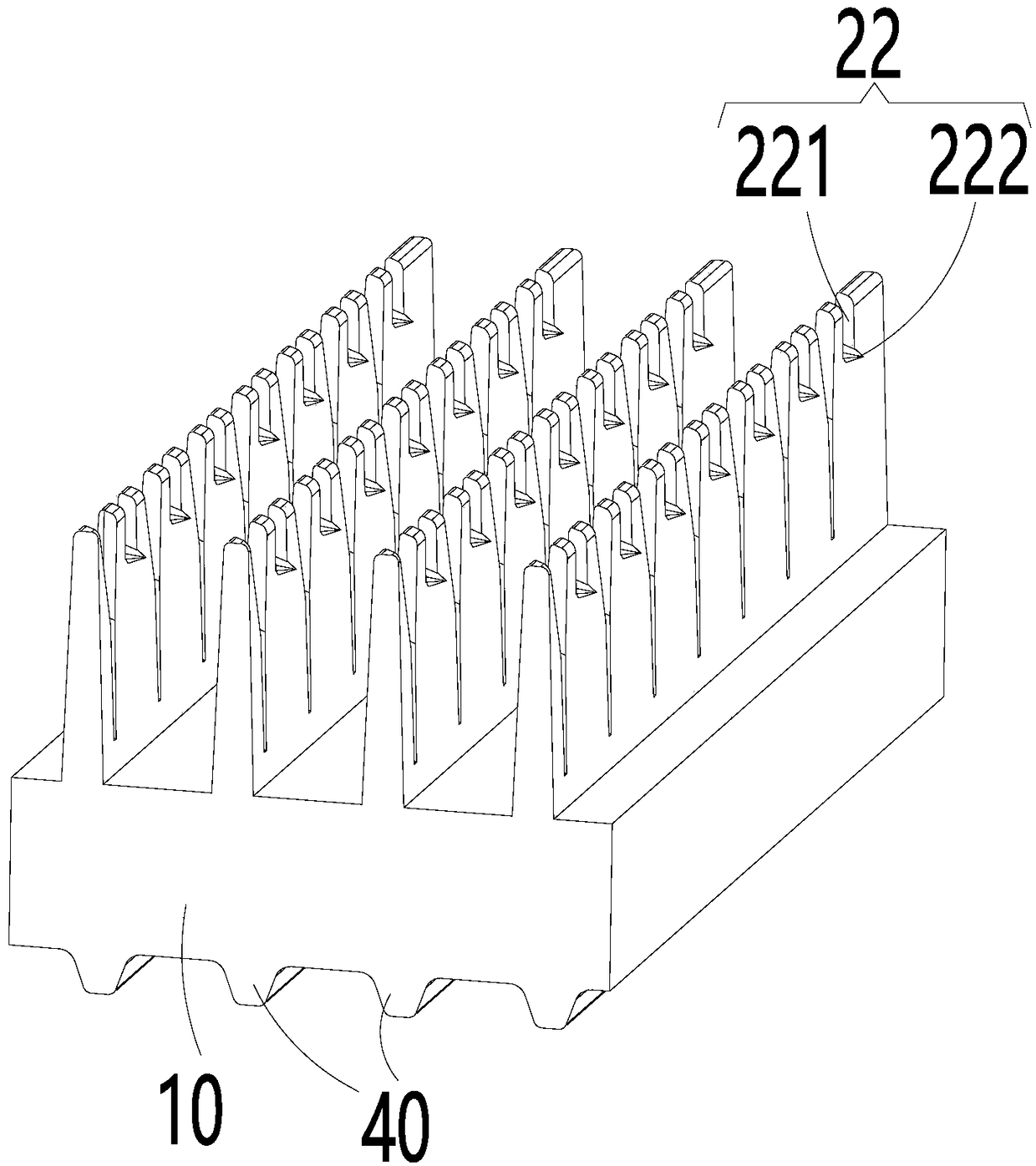

[0031] figure 1 An embodiment of the heat exchange tube of the present invention is shown, the heat exchange tube includes a tube body 10 and fins 20 arranged on the outer surface 11 of the tube body 10 , channels 30 are formed between adjacent fins 20 . The fins 20 are provided with communication grooves 21 , the communication grooves 21 communicate with the adjacent channels 30 , and the communication grooves 21 are used for circulating refrigerant.

[0032] Applying the technical scheme of the present invention, through the communication groove 21 opened on the fin 20, the adjacent channels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com