Cold drum or crude benzene section waste gas treatment device and intelligent pressure maintaining and oxygen control method

A waste gas treatment device, crude benzene technology, applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve problems such as affecting product quality, increasing the difficulty of waste gas treatment process, affecting gas calorific value, etc., to reduce costs. and the difficulty of the treatment process, beneficial to the quality of waste gas treatment, and the effect of avoiding hidden dangers in safe production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

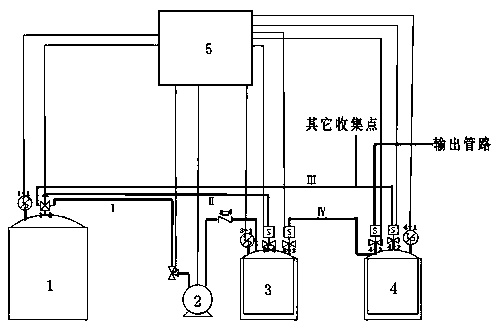

[0027] As shown in the accompanying drawing, a cold drum or crude benzene section waste gas treatment device includes a controller 5, a gas compressor 2, a material storage tank 1, a collection pressure storage tank 3, a treatment tank 4, a pressure sensor, and an oxygen concentration detection The material storage tank 1 produces volatile waste gas, which is concentrated in the cavity above the material storage tank 1. The pressure storage tank 3 is connected to the material storage tank 1 through the pipeline I. The pipeline I is equipped with a gas compressor 2 and a control Connected to the device 5, the collection pressure storage tank 3 collects the waste gas generated by the material storage tank 1 through the pipeline I for storage and standby, and the collection pressure storage tank 3 communicates with the material storage tank 1 through the pipeline II to pump the material storage tank 1 Or pressurize and return gas, the treatment tank 4 is connected with the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com