Intelligent monitoring system for dilute oil lubrication device, and operating method thereof

A thin oil lubrication and monitoring system technology, which is applied in the direction of lubricating parts, engine lubrication, electrical program control, etc., to achieve the effect of long service life, scientific and reasonable design, and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

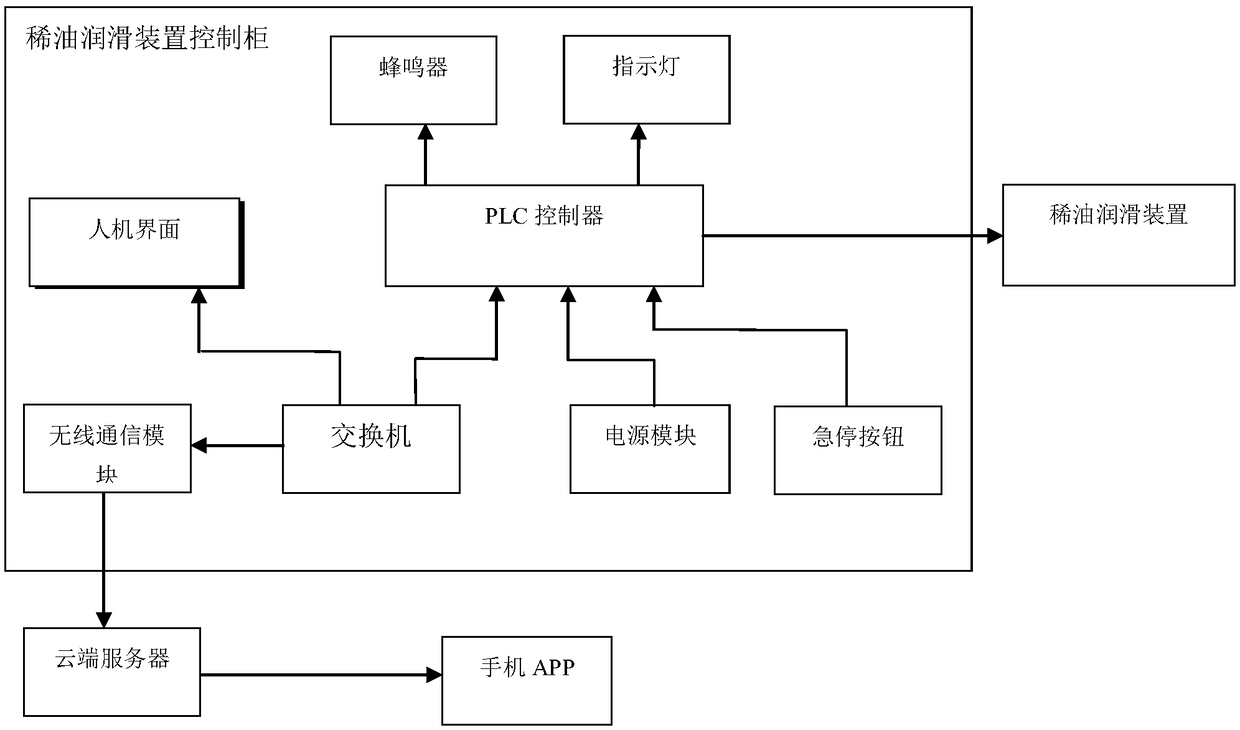

[0054] like figure 1 As shown, an intelligent thin oil lubrication device monitoring system includes a thin oil lubrication device, a control cabinet, a cloud server and terminal equipment;

[0055] The control cabinet is equipped with a PLC controller, a power module, a switch, and a wireless communication module;

[0056] The door of the control cabinet is equipped with a touch screen, indicator light, buzzer and emergency stop button;

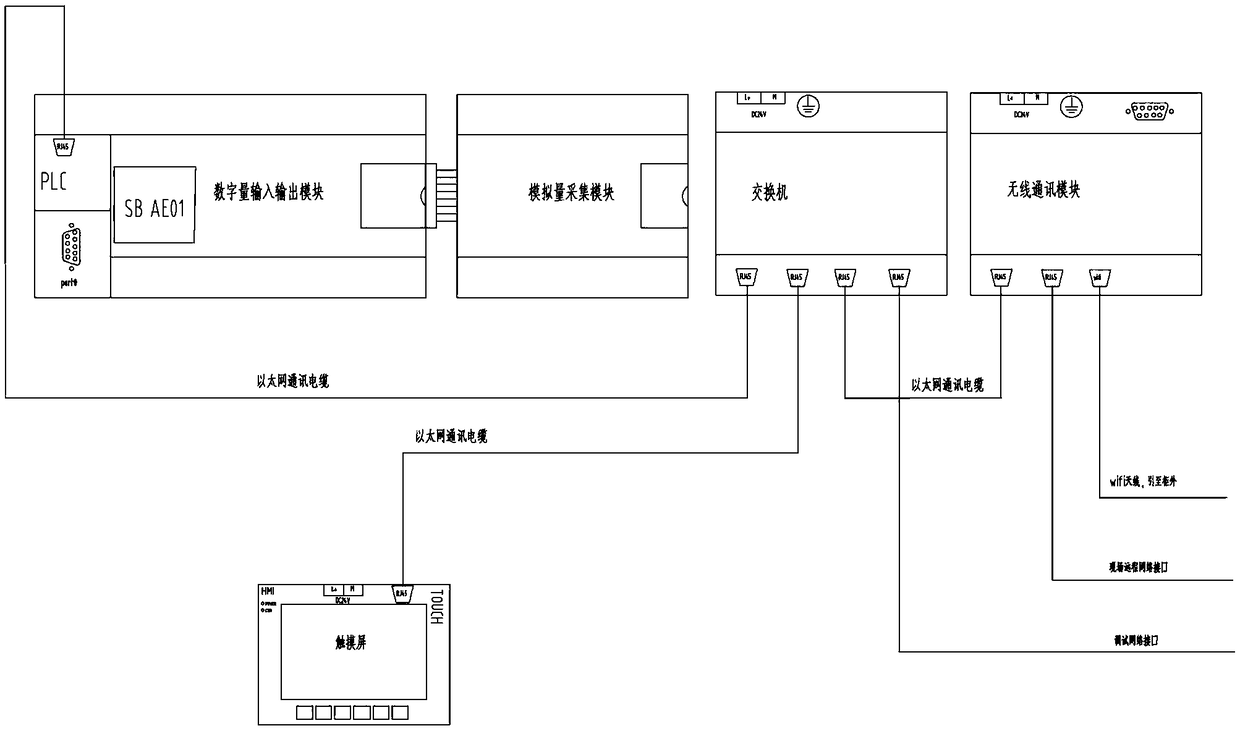

[0057] like figure 2 As shown, the PLC controller integrates the Ethernet communication interface, and the Ethernet communication interface is connected with the touch screen and the wireless communication module through the switch for data exchange; the wireless communication module transmits the coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com