Excavation piling and filling method

A technology for digging hole piles and pile holes, which is applied to sheet pile walls, buildings, and foundation structure engineering, etc. It can solve the problems of inability to ensure the compactness of pile heads, waste concrete, increase labor costs, etc., and reduce the process of removing pile heads , saving concrete and ensuring compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is described further as follows:

[0020] The pouring method for digging piles comprises the following steps:

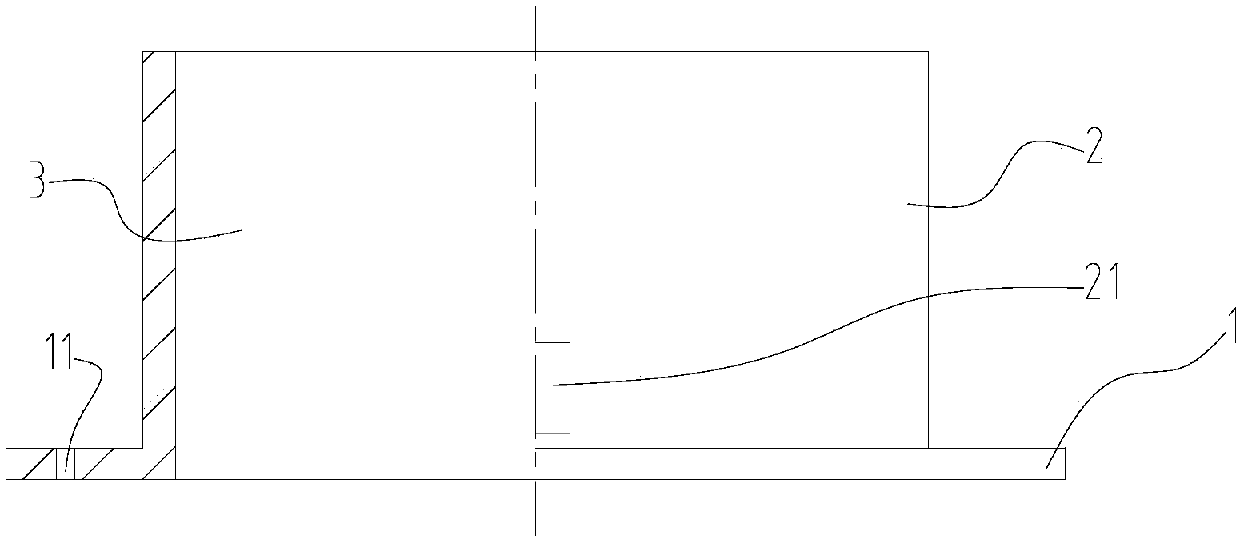

[0021] Step 1, making a steel mold: the steel mold includes a base 1 and a columnar steel mold body 2 in the same shape as the pile hole; along the axial direction of the steel mold body 2, one end of the steel mold body 2 is the bottom end, and the other end is the top end The base 1 is fixedly connected to the bottom end of the steel mold body 2; along the steel mold body 2 axially, a through hole 3 passing through the base 1 and the steel mold body 2 is provided, and the steel mold body 2 is provided with a through hole 3 The hole 3 runs through to the slurry discharge hole 21 on the outside of the steel mold body 2;

[0022] Step 2. Install the steel mold at the design elevation of the pile top;

[0023] Step 3. Pour concrete into the pile hole from the steel mold. When p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com