Separation device for waste incineration

A separation device and waste incineration technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of inability to separate slag, insufficient separation, etc., and achieve the effect of reducing the filtering effect and improving the separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

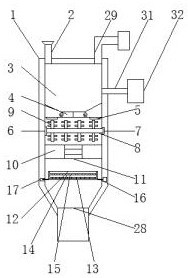

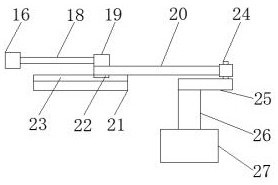

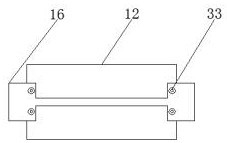

Embodiment 1

[0025] Example 1 as Figure 1-4 As shown, the waste incineration separation device according to the embodiment of the present invention includes an incinerator body 1, the top of the incinerator body 1 is provided with a feed pipe 2, and the top in the incinerator body 1 is provided with an incineration chamber 3, and the incineration chamber The bottom end of 3 is provided with revolving door 4, and the bottom end of incineration chamber 3 is provided with the refrigeration block 5 that is arranged symmetrically, and one side in incinerator body 1 is provided with motor-6, and the other side in incinerator body 1 Be provided with groove 7, one side of motor one 6 is provided with the rotating shaft one 8 that matches with groove 7, and rotating shaft one 8 cover is provided with some evenly distributed stirring rods 9, is provided with in the incinerator body 1 and is connected with it. Fixed plate-10, the top of fixed plate-10 is provided with through pipe 11, is provided wi...

Embodiment 2

[0026] Embodiment 2 is on the basis of embodiment 1 such as figure 1 As shown, according to the waste incineration separation device according to the embodiment of the present invention, one side of the incinerator body 1 is provided with a ventilation pipe 31 extending to the incineration chamber 3 , and one side of the ventilation pipe 31 is provided with a fan 32 . It is not difficult to see from the above-mentioned design that by arranging the ventilation pipe 31 and the fan 32, the garbage can be burned faster and the combustion effect of the incineration chamber 3 can be effectively improved.

Embodiment 3

[0027] Embodiment 3 is such as on the basis of embodiment 1 figure 1 As shown, according to the waste incineration separation device used in the embodiment of the present invention, the top of the feeding pipe 2 is provided with a feeding port, and the feeding port is a trumpet structure. It is not difficult to see from the above-mentioned design that the feeding port is configured as a trumpet structure, which is convenient for garbage to enter the feeding pipe 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com