A kind of pyrolysis treatment process of tire rubber

A cracking treatment and rubber technology, which is applied in the field of tire rubber cracking treatment process, can solve the problems of slow cracking speed, poor recycling effect and low recycling rate of cracking products in the cracking process, so as to achieve long-term efficient work and avoid energy consumption. Loss, the effect of improving the recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

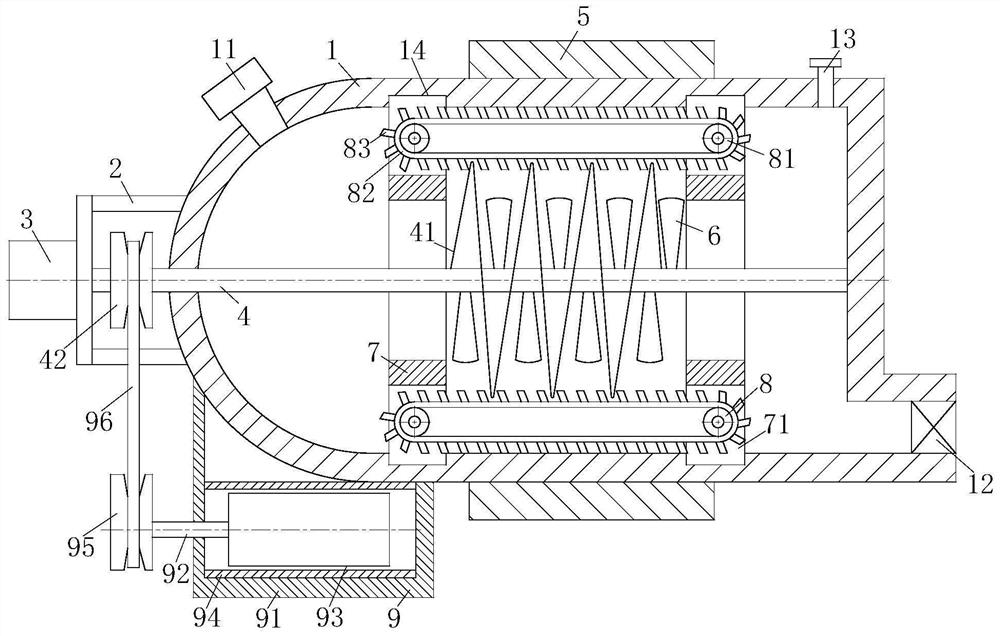

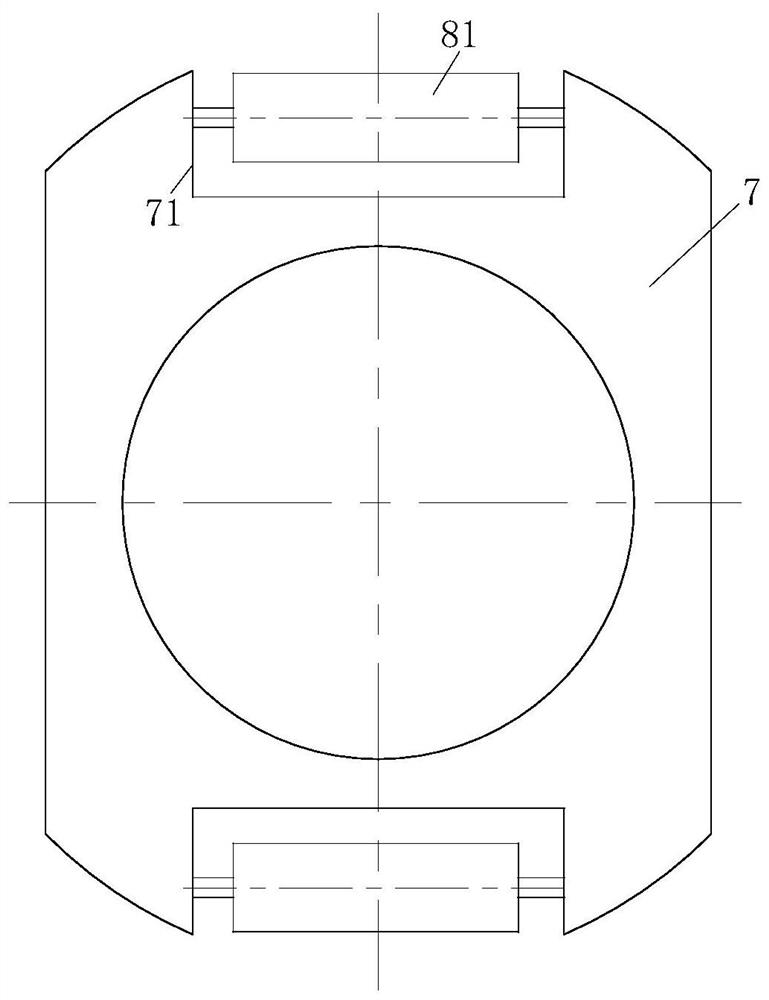

[0024] use as Figure 1-Figure 3 The tire rubber cracking treatment process according to one embodiment of the present invention will be described as follows.

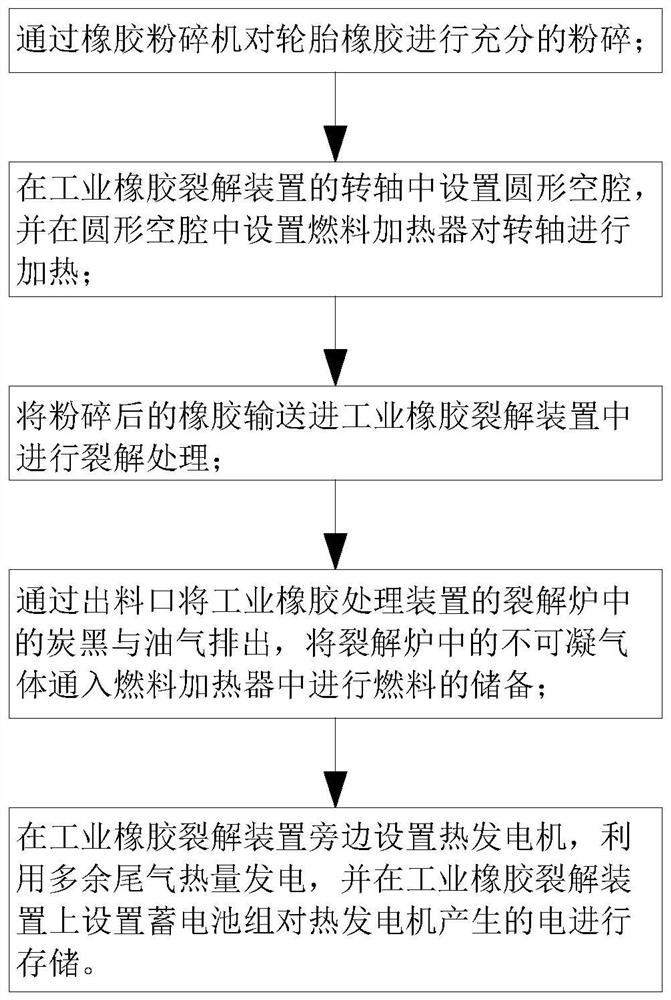

[0025] like Figure 1 to Figure 3 Shown, a kind of cracking treatment process of tire rubber of the present invention, this process comprises the steps:

[0026]S1: The tire rubber is fully pulverized by the rubber pulverizer, so as to speed up the heating speed of the rubber, speed up the cracking speed, and at the same time make the rubber cracking more fully and improve the work efficiency;

[0027] S2: After pulverization in S1, a circular cavity is set in the rotating shaft of the industrial rubber cracking device, and a fuel heater is set in the circular cavity to heat the rotating shaft, which increases the heating area of the rubber and enables the rubber to be processed more quickly. Thermal cracking, further improving work efficiency;

[0028] S3: After heating in S2, the pulverized rubber is transported...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com