Method for degrading high-polymeric procyanidine

A proanthocyanidin and polymer technology, applied in organic chemistry and other directions, can solve the problems of high molecular structure destructive, prolong catalyst activity retention time, reduce catalyst dosage, etc., achieve stable catalytic activity, less ionic liquid dosage, and storage time. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

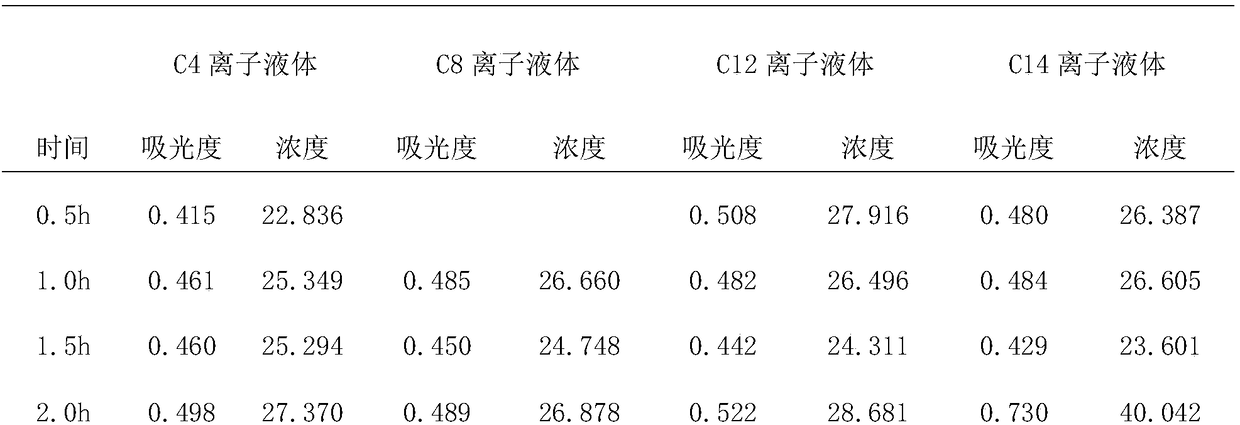

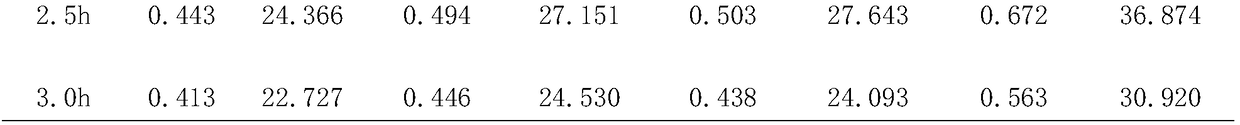

Examples

Embodiment 1

[0037] Quaternary ammonium salt ionic liquid-C4 ionic liquid, the preparation method is as follows:

[0038] First weigh 1,3-propane sultone and N,N-dimethylbutylamine, the molar ratio of the two substances is 0.8:1, then weigh 1,3-propane sultone and quaternary ammonium salt 4 times the total volume of ethyl acetate, first add 1,3-propane sultone and ethyl acetate to the reaction vessel, and then slowly add N,N-dimethylbutylamine to the reaction through a constant pressure dropping funnel In the container, stir while adding the quaternary ammonium salt dropwise; after adding the three substances into the reaction container, stir and react at 60°C for 2h (white precipitation will occur during the reaction), cool down to room temperature after the reaction, and then Suction filtration is carried out to obtain solid precipitation; The solid precipitation obtained is washed with ethyl acetate, and each milligram of solid precipitation is washed with 3 milliliters of ethyl acetate...

Embodiment 2

[0041] Quaternary ammonium salt ionic liquid-C8 ionic liquid, the preparation method is as follows:

[0042] First weigh 1,3-propane sultone and N,N-dimethyl n-octylamine, the molar ratio of the two substances is 1:1, then weigh 1,3-propane sultone and quaternary ammonium Ethyl acetate 5 times the total volume of the salt, first add 1,3-propane sultone and ethyl acetate to the reaction vessel, and then slowly add N,N-dimethyl n-octylamine through the constant pressure dropping funnel Add in the reaction vessel, stir while adding the quaternary ammonium salt dropwise; After all the three substances are added into the reaction vessel, stir and react at 65°C for 2.5h (white precipitates will be produced during the reaction), and cool down to At room temperature, suction filtration is carried out again to obtain solid precipitation; The solid precipitation obtained is washed with ethyl acetate, and each milligram of solid precipitation is washed with 4 milliliters of ethyl acetate...

Embodiment 3

[0045] Quaternary ammonium salt ionic liquid-C12 ionic liquid, the preparation method is as follows:

[0046] First weigh 1,3-propane sultone and N,N-dimethyldodecylamine, the molar ratio of the two substances is 1.2:1, then weigh 1,3-propane sultone and 6 times the total volume of quaternary ammonium salt, first add 1,3-propane sultone and ethyl acetate into the reaction vessel, and then add N,N-dimethyl dodecyl Alkylamine is slowly added to the reaction container, and the quaternary ammonium salt is added dropwise while stirring; after all three substances are added to the reaction container, the reaction is stirred at 70°C for 3 hours (white precipitates will be produced during the reaction), and the reaction is over After being cooled to room temperature, carry out suction filtration to obtain solid precipitation again; The solid precipitation obtained is washed with ethyl acetate, and each milligram of solid precipitation is washed with 5 milliliters of ethyl acetate for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com