Fiber shearing method and device for 3D printing of continuous fiber reinforced composite material

A reinforced composite material and continuous fiber technology, applied in the field of 3D printing, can solve the problems of poor reliability, limited range of applicable materials, and high requirements for calculation and control accuracy, so as to reduce the requirements of calculation and control accuracy, improve efficiency and stability, Calculate and control effects requiring high precision

Pending Publication Date: 2018-12-28

陕西斐帛科技发展有限公司

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the shearing device on the existing 3D printer has technical problems such as poor reliability, limited range of applicable materials, and high requirements for calculation and control accuracy of the printing process.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

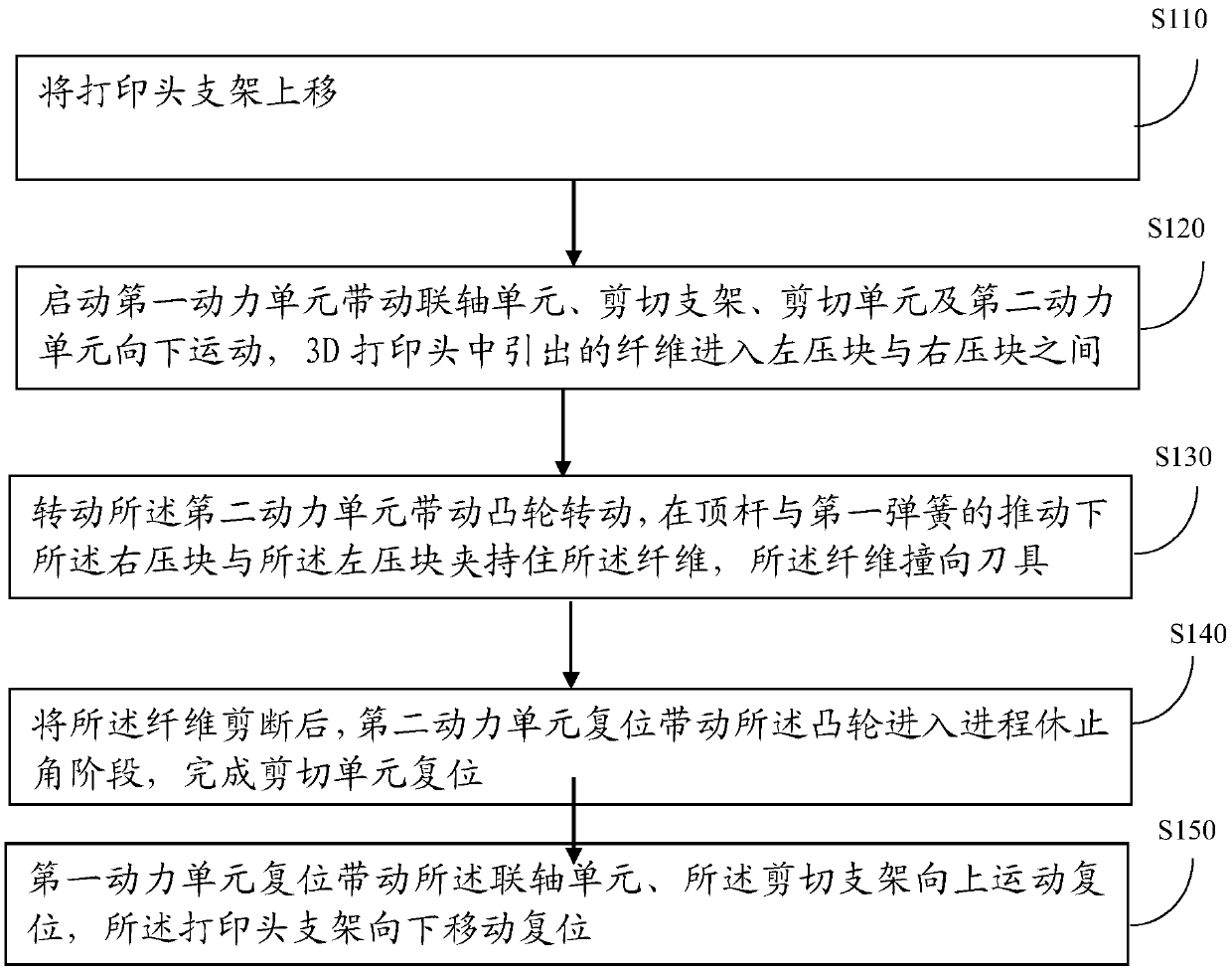

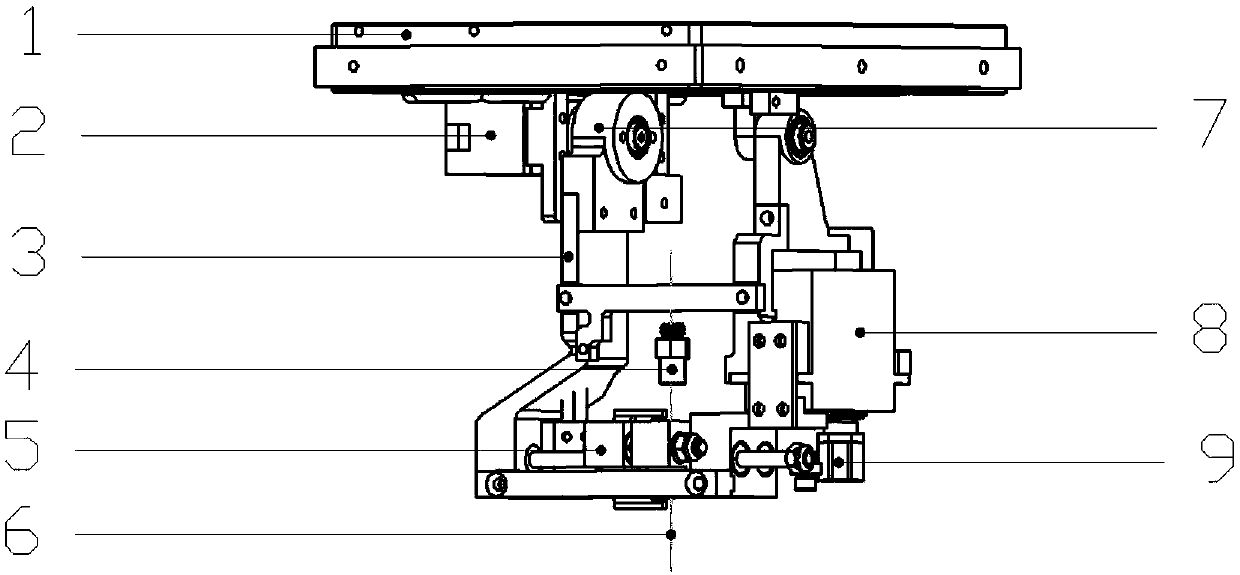

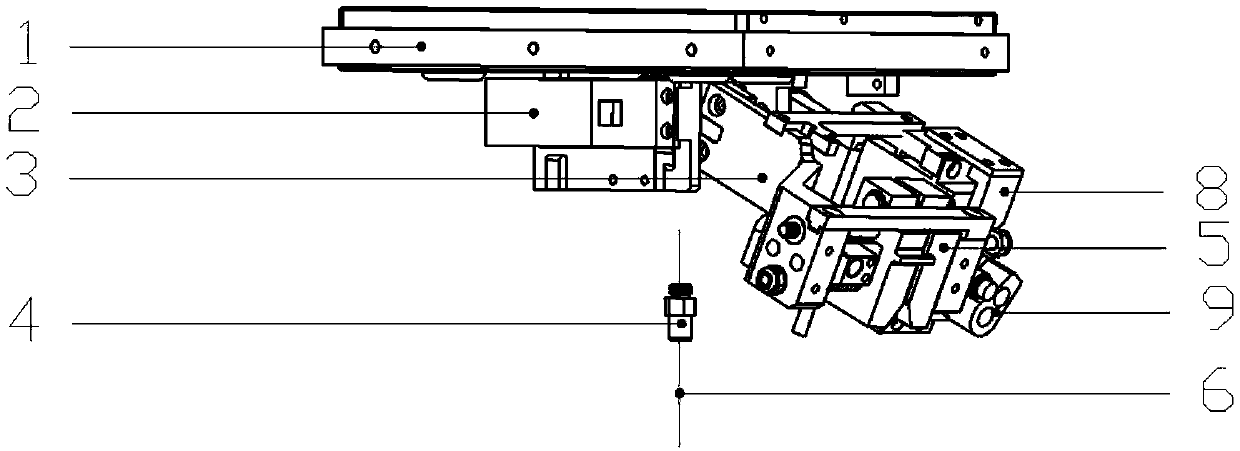

The invention provides a fiber shearing method and device for 3D printing of a continuous fiber reinforced composite material. The method comprises the following steps: a printing head bracket is moved upwards; a first power unit is started to drive a coupling unit, a shearing bracket, a shearing unit and a second power unit to move downwards, and fibers led out of a 3D printing head enter betweena left pressing block and a right pressing block; the second power unit is rotated to drive a cam to rotate, and the fibers are clamped by the right pressing block and the left pressing block under pushing of an ejector rod and a first spring; after the fibers are sheared, the second power unit resets to drive the cam to enter a process repose angle stage, and reset of the shearing unit is completed; the print head bracket moves downwards to reset. The technical problems that existing shearing devices have poor reliability, limited applicable material range and high requirement on calculationand control precision in the printing process are solved, and the technical effects of improving printing efficiency and stability of the composite material, reducing the requirement on calculation and control precision and saving cost are achieved.

Description

technical field The invention relates to the technical field of 3D printing, in particular to a fiber shearing method and device for 3D printing of continuous fiber reinforced composite materials. Background technique Continuous fiber reinforced composites have the advantages of high specific strength, high specific modulus, strong designability and functionality (such as wave absorption and heat insulation), and are widely used in aerospace, high-speed trains and ships. The traditional manufacturing process of continuous fiber reinforced composite materials, such as winding molding process, automatic laying process and weaving process, etc., all require molds, high cost and long cycle, and it is impossible to manufacture complex continuous fiber reinforced composite parts. The application of continuous fiber reinforced composites is greatly limited. In recent years, with the emergence of continuous fiber reinforced composite material 3D printing process, not only the manuf...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B29C64/118B29C64/227B29C64/30B33Y30/00

CPCB29C64/118B29C64/227B29C64/30B33Y30/00

Inventor 于慧莉李强田小永曹毅刘腾飞侯章浩

Owner 陕西斐帛科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com