4D printing process method capable of presetting internal stress

A process method and technology of internal stress, applied in the field of additive manufacturing, can solve the problem of precise control of material mechanical properties, restrictions on the promotion and use of 4D printing samples, self-repair of 4D printing samples, self-assembly environment adaptation and other unstable performances, etc. problems, to achieve the effect of enriching stress control means, enriching types and performance, and improving operability

Active Publication Date: 2018-12-28

XI AN JIAOTONG UNIV

View PDF5 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the characteristics of 4D printing structures with multiple materials and multiple filling structures, and there are currently few researches on numerical models and simulation software specifically for multiple materials, large deformation, and multiple couplings, it is difficult to accurately control the mechanical properties of samples with external excitation. , resulting in unstable performance of 4D printing samples such as self-repair, self-assembly, and environmental adaptation, which greatly limits the promotion and use of 4D printing samples in actual engineering projects

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

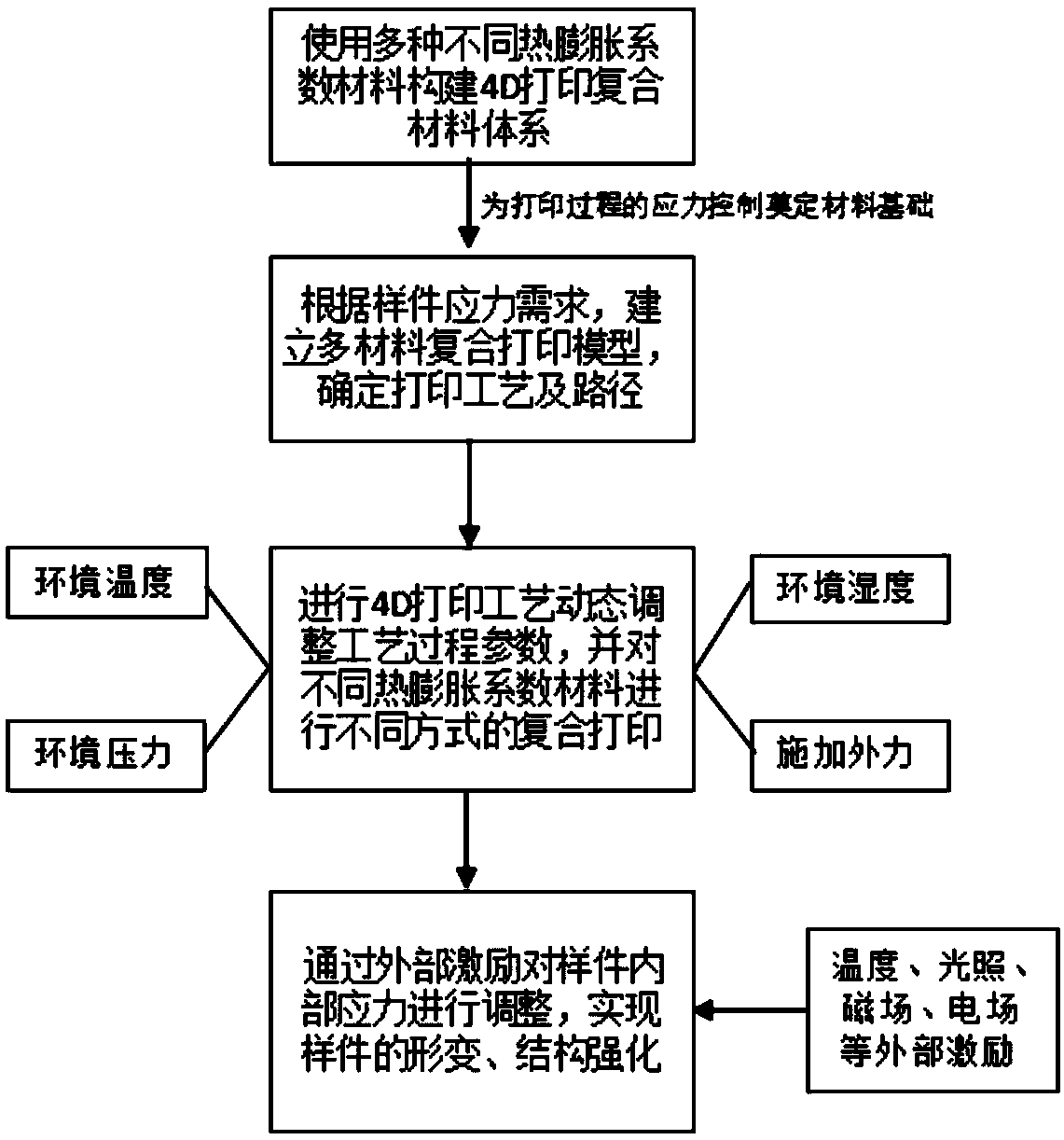

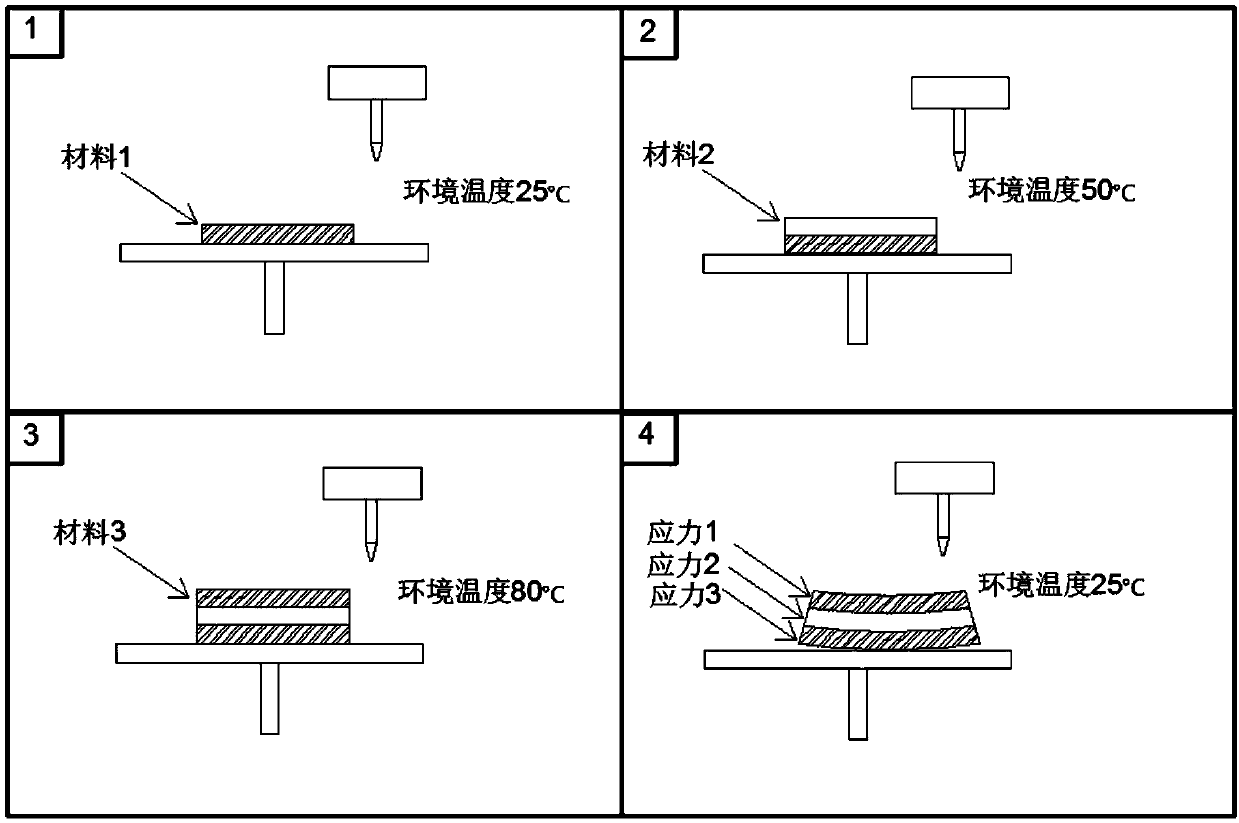

The invention discloses a 4D printing process method capable of presetting internal stress. Different grades of thermal expansion coefficient materials are used to construct a composite system, so that different thermal expansion coefficient materials change with temperature environment and the like during processing to produce different degrees of strain an stress; a 3D printed additive manufacturing process or a 3D printing process and traditional processing manner mixed process is used for preparing samples; energy accumulation and internal stress distribution control of different spatial position materials are realized through ordered and controllable change of material composition manner, external environment and printing process parameters. The 4D printed composite system constructedthrough composition printing of multiple materials lays a material foundation for stress control during printing, and accurate control of stress, strain and deformation of samples during printing arerealized under the control of multiple factors such as material distribution, process parameters and environment parameters in the printing process.

Description

technical field The invention belongs to the technical field of additive manufacturing, and in particular relates to a 4D printing process method with internal stress preset. Background technique 4D printing technology adds a time dimension to the basis of 3D printing. The deformation design is built into the printed material. The function, shape, and properties of the structure obtained by 4D printing can evolve over time under external stimulation, and It has the functions of self-repair, self-assembly, self-diagnosis, self-learning and environmental adaptation, realizing the integration of product design, manufacturing and assembly. At present, 4D technology as a whole is still in the stage of laboratory exploration. The current 4D printing technology usually uses shape memory functional materials or multiple hybrid materials for additive manufacturing, and applies external excitation (thermal, magnetic, electric, acoustic, etc.) to the printed structure. , light) to pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B29C64/10B33Y10/00

CPCB29C64/10B33Y10/00

Inventor 王玲郑纪豹李涤尘

Owner XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com