Electrostatic-piezoelectric hybrid drive transceiver integrated cmut, its use method and preparation method

A hybrid drive, piezoelectric technology, applied in the direction of the fluid that utilizes vibration, can solve the problem of not being able to achieve high-performance ultrasonic transmission and reception at the same time, and achieve the effect of improving the receiving sensitivity, improving the vibration displacement of the film, and improving the transmitting and receiving sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below, the present invention is described in detail in conjunction with accompanying drawing and embodiment:

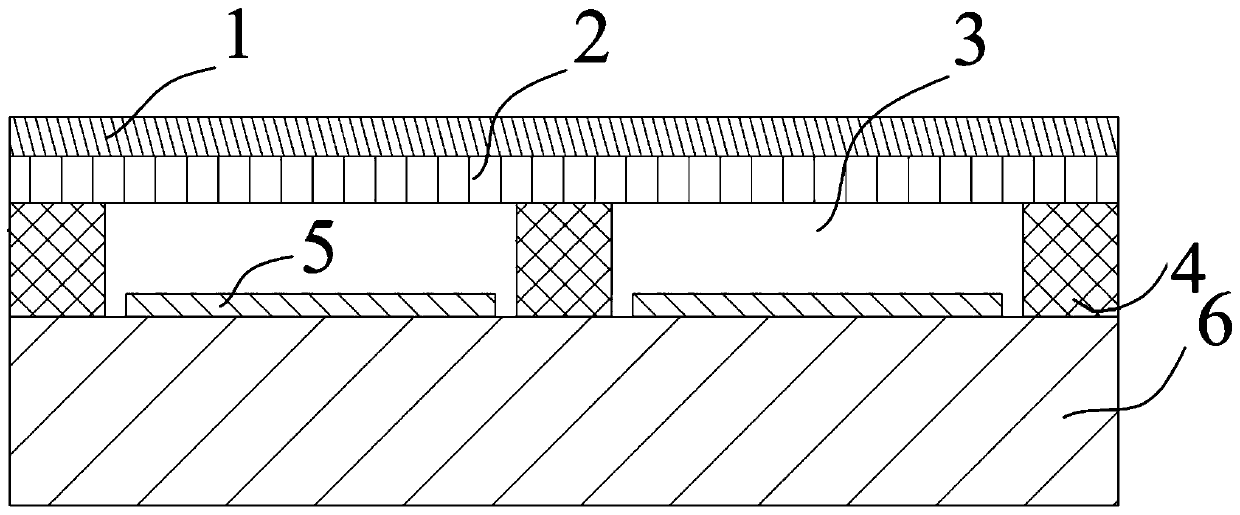

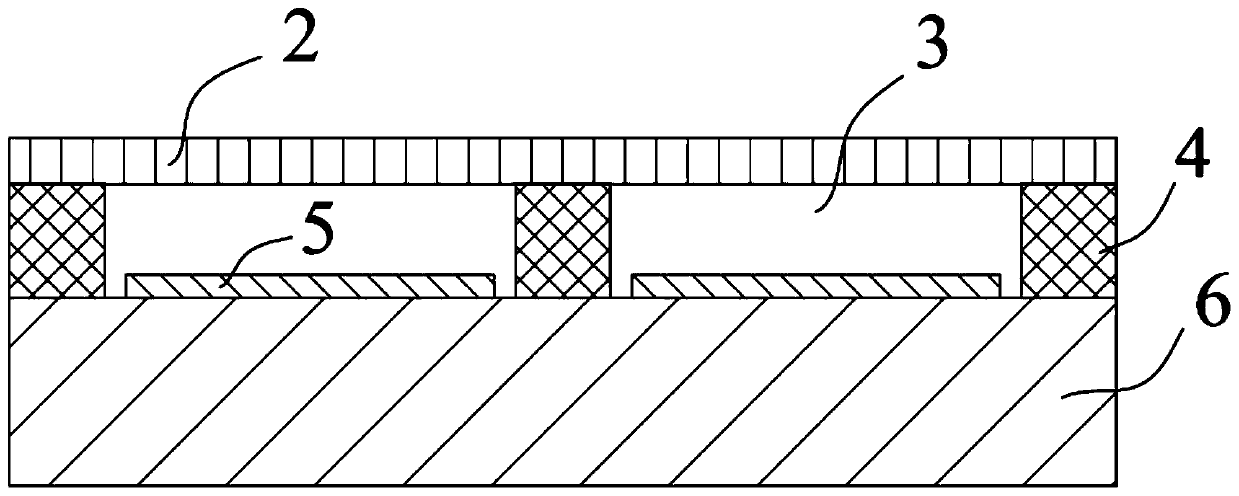

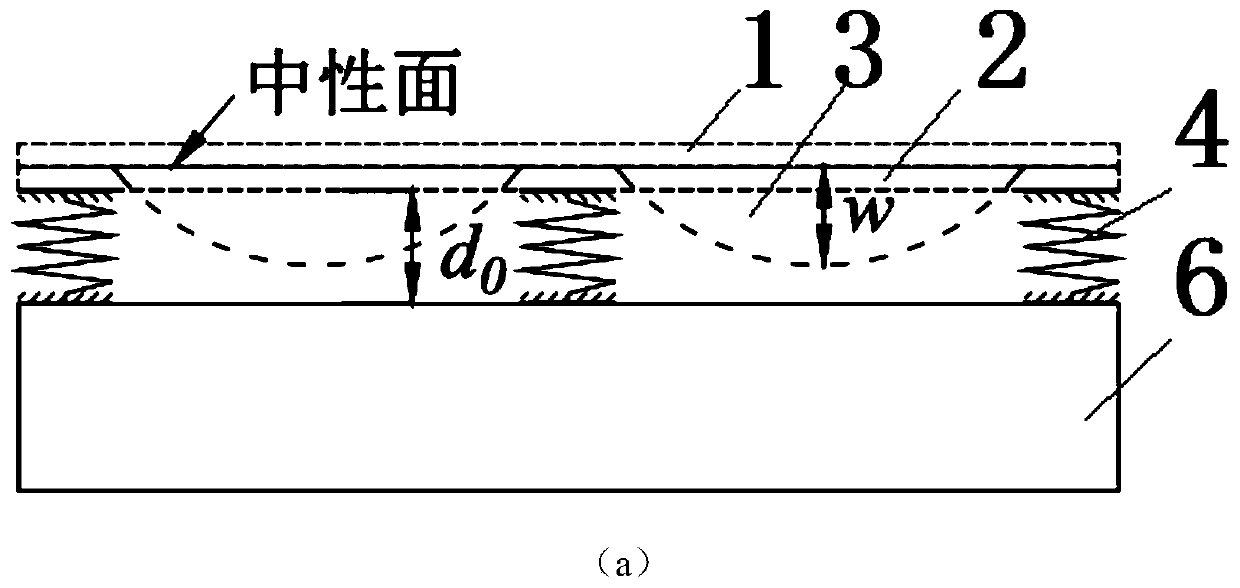

[0048] like figure 1 As shown, the electrostatic-piezoelectric hybrid drive transceiver integrated CMUT of the present invention includes an upper electrode 1, a vibrating membrane 2, a cavity 3, a piezoelectric pillar 4, an insulating layer 5 and a lower electrode 6;

[0049] Among them, the piezoelectric pillar 4 is made of piezoelectric material, and the piezoelectric pillar 4 adopts PZT piezoelectric material, AlN piezoelectric material, PVDF piezoelectric material or ZnO piezoelectric material; and mainly uses its d 33 The piezoelectric coefficient, that is, the direction of the electric field in the area of the piezoelectric pillar is consistent with the direction of the stretching vibration of the pillar. The purpose of using the piezoelectric pillar 4 is: under the action of positive and negative polarity voltage, it can produce telescopic deformatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com