Toilet bowl pad and production process thereof

A production process and technology for toilet mats, which are applied in the field of toilet mats, can solve the problems of flannel being easy to be dirty and difficult to wash, easy to store bacteria and cause diseases, not energy saving and environmental protection, etc., and achieve the effects of simple and easy-to-obtain materials, convenient operation, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

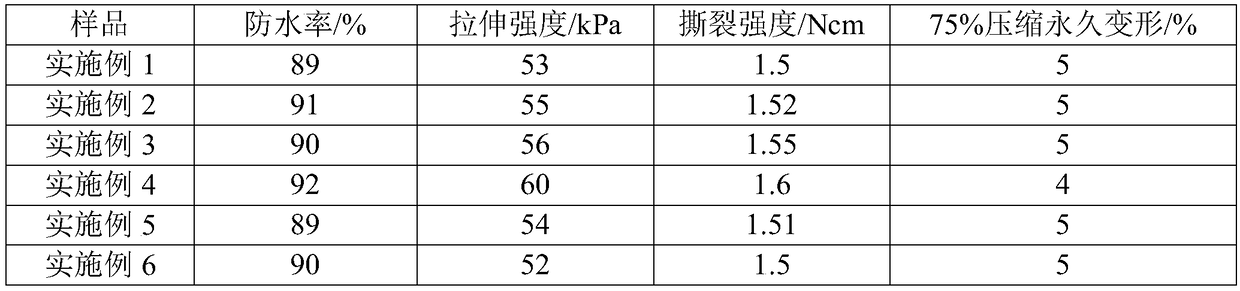

Embodiment 1

[0039] The preparation of ETPU particle 11 comprises the steps:

[0040]Weigh 50g of carbamate, 36g of monoisocyanate, 5.8g of polyisocyanate, 8g of 1,2-propylenediamine and 0.2g of silver ion antibacterial agent, and then weigh the carbamate, monoisocyanate, polyisocyanate, 1,2-Propylenediamine and silver ion antibacterial agent are mixed and stirred evenly, heated and pressurized under the conditions of 80°C and 10Mpa, and then granulated to obtain ETPU granules with a diameter of 8mm and a taper.

[0041] A kind of production technology of toilet seat pad comprises the steps:

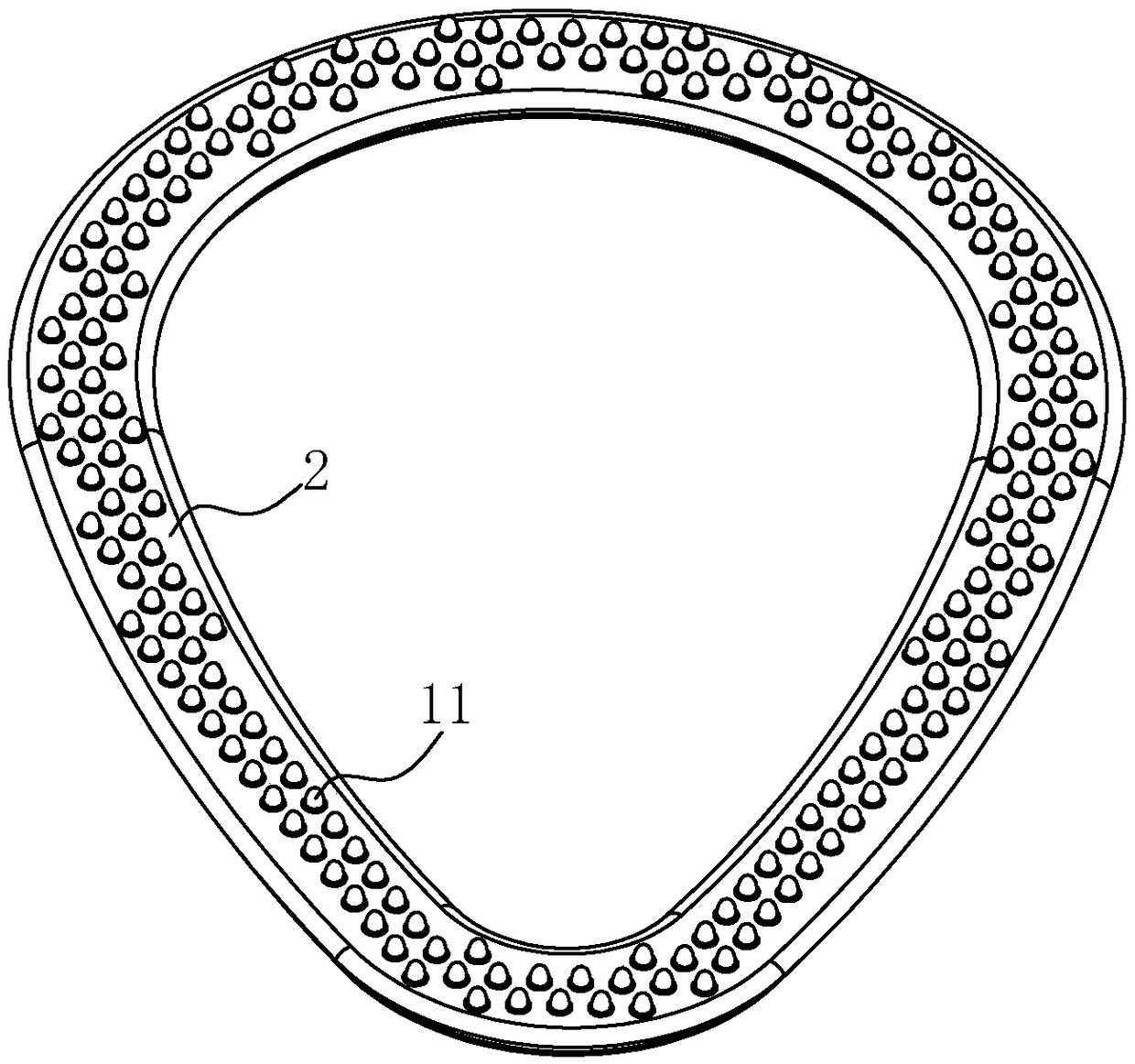

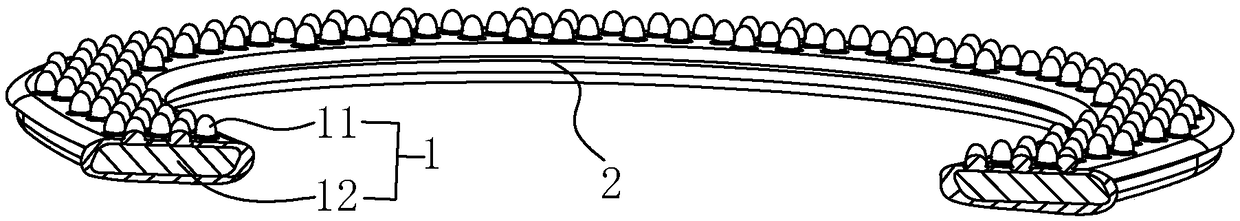

[0042] Such as figure 1 , 2 As shown, the ETPU particles 11 and PU glue 12 are mixed in a ratio of 3:1 by weight, and then stirred evenly; the PU is injected into the mold, and the mold is sucked under the air pressure of 8kg, and the PU film (2) is formed; The ETPU particles 11 and PU glue 12 are quantitatively transported into the mold, heated at 90°C for 8 minutes, and poured according to the m...

Embodiment 2

[0044] The preparation of ETPU particle 11 comprises the steps:

[0045] Weigh 64.7g of carbamate, 24g of monoisocyanate, 6g of polyisocyanate, 5g of 1,2-propylenediamine and 0.3g of silver ion antibacterial agent, and then weigh the carbamate, monoisocyanate, polyisocyanate, 1,2-Propylenediamine and silver ion antibacterial agent are mixed and stirred evenly, heated and pressurized under the conditions of 100°C and 15Mpa, and then granulated to obtain ETPU granules with a diameter of 9mm and a taper.

[0046] A kind of production technology of toilet seat pad comprises the steps:

[0047] Such as figure 1 , 2 As shown, ETPU particles 11 and PU glue 12 are mixed in a weight ratio of 3.2:1, and then stirred evenly; the PU is injected into the mold, and the mold is sucked under 12kg air pressure, and the PU film (2) is formed; The ETPU particles 11 and PU glue 12 are quantitatively transported into the mold, heated at 100°C for 10 minutes, and cast according to the model of t...

Embodiment 3

[0049] The preparation of ETPU particle 11 comprises the steps:

[0050] Weigh 55g of carbamate, 33g of monoisocyanate, 5.6g of polyisocyanate, 6g of 1,2-propylenediamine and 0.4g of silver ion antibacterial agent, and then weigh the carbamate, monoisocyanate, polyisocyanate, 1,2-Propylenediamine and silver ion antibacterial agent are mixed and stirred evenly, heated and pressurized under the conditions of 90°C and 11Mpa, and then granulated to obtain ETPU granules with a diameter of 10mm and a taper.

[0051] A kind of production technology of toilet seat pad comprises the steps:

[0052] Such as figure 1 , 2 As shown, ETPU particles 11 and PU glue 12 are mixed in a weight ratio of 3.4:1, and then stirred evenly; the PU is injected into the mold, and the mold is sucked under 10kg air pressure, and the PU film (2) is formed; The ETPU particles 11 and PU glue 12 are quantitatively transported into the mold, heated at 110°C for 12 minutes, and poured according to the model of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com