Environmentally friendly deoxidizer and preparation method thereof

A deoxidizer and environmental protection technology, applied in the field of deoxidizer, can solve the problems of high cost, unacceptable, slow oxygen absorption rate of deoxidizer, etc., and achieve the effect of reducing manufacturing cost and good deoxidizing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

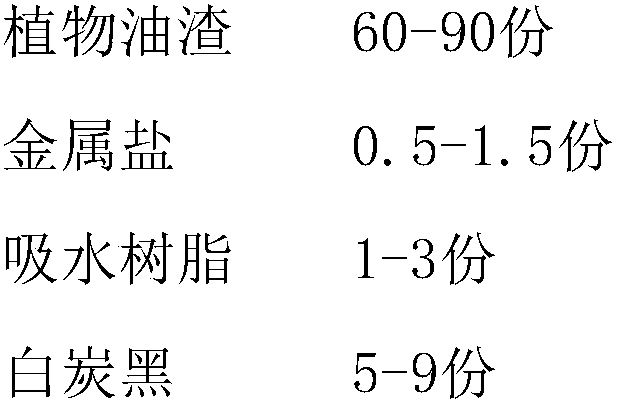

[0034] A kind of environment-friendly deoxidizer, described environment-friendly deoxidizer comprises the raw material of following weight portion:

[0035]

[0036] The vegetable oil residue is peanut oil residue.

[0037] The metal salt is ferric chloride.

[0038] A preparation method of an environment-friendly deoxidizer, first crushing vegetable oil residue, then putting the crushed vegetable oil residue, metal salt, water-absorbing resin and white carbon black into a mixer, adding water while stirring, and adding vermiculite and activated carbon after stirring evenly , continue to stir evenly, discharge and sieve to obtain an environmentally friendly deoxidizer.

Embodiment 2

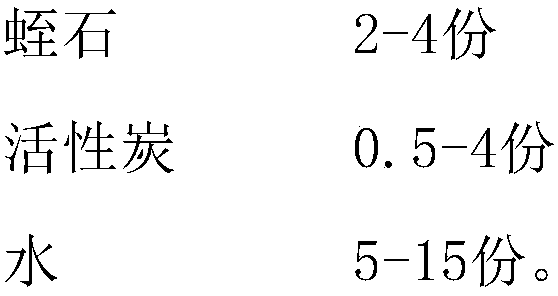

[0040] The difference between this embodiment and the above-mentioned embodiment 1 is that the environmentally friendly deoxidizer includes the following raw materials in parts by weight:

[0041]

[0042] The vegetable oil residue is rapeseed oil residue.

Embodiment 3

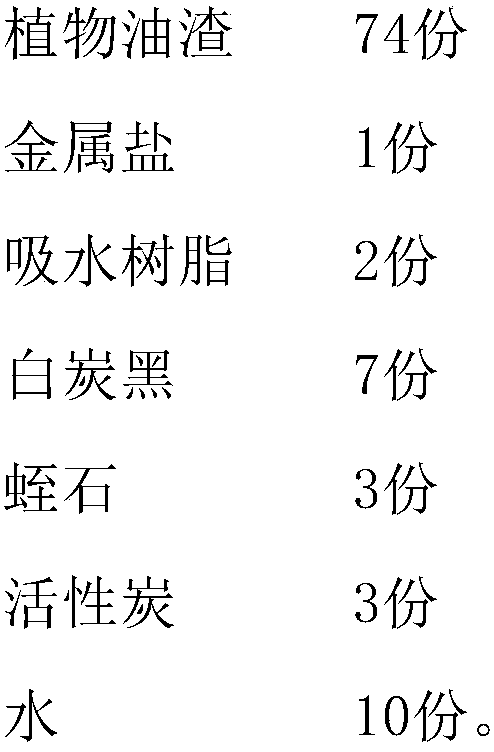

[0045] The difference between this embodiment and the above-mentioned embodiment 1 is that the environmentally friendly deoxidizer includes the following raw materials in parts by weight:

[0046]

[0047] The vegetable oil residue is soybean oil residue.

[0048] The metal salt is iron sulfate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com