Water treatment method for steam boiler

A steam boiler and water treatment technology, applied in the field of water treatment, can solve the problems of waste of fuel, overheating of boiler metal materials, high equipment cost, etc., and achieve the effects of reducing the frequency of scale removal, prolonging the time of scale inhibition, and good oxygen removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-5

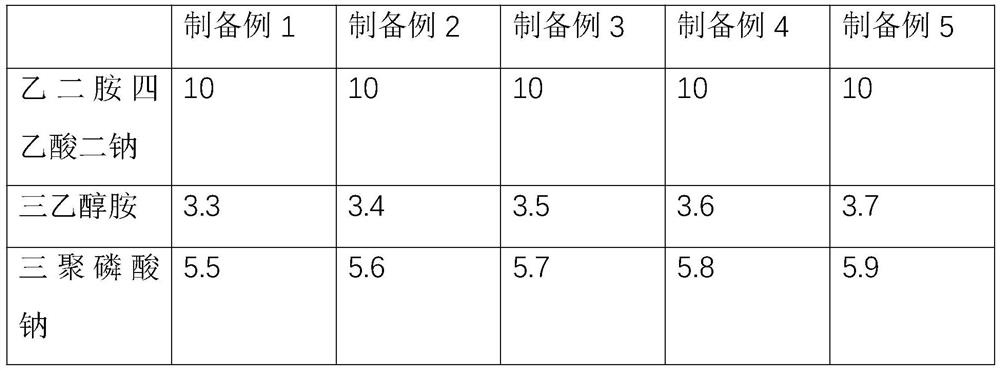

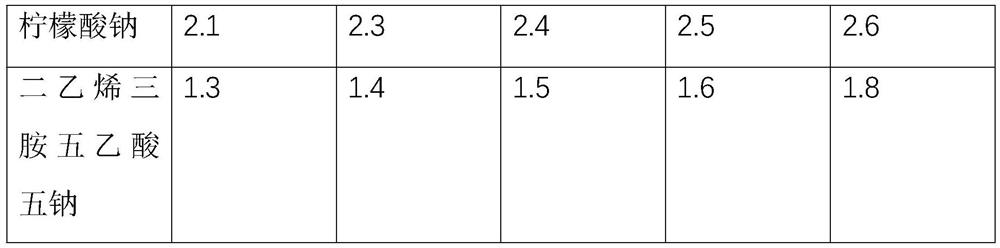

[0049] A water treatment agent comprising the following components:

[0050] Disodium EDTA, Triethanolamine, Sodium Tripolyphosphate, Sodium Citrate, Pentasodium Diethylenetriaminepentaacetate.

[0051] In Preparation Examples 1-5, see Table 2 for the specific input amount (unit: kg) of each component.

[0052] Table 2

[0053]

[0054]

[0055] In preparation example 1-5, the preparation method of water treatment agent is as follows:

[0056] Put disodium ethylenediamine tetraacetate, triethanolamine, sodium tripolyphosphate, sodium citrate, pentasodium diethylenetriaminepentaacetate into the stirring tank, rotate at 60r / min, stir for 3min, stop stirring, let stand for 60min, and obtain The mixture is passed through a 200-mesh sieve to obtain a water treatment agent.

[0057] By standing still, the bubbles will overflow by themselves, reducing harmful bubbles, and by sieving, destroying the bubbles, reducing the bubble content in the water treatment agent, and improv...

Embodiment 1

[0059] A steam boiler water treatment method, comprising the following steps:

[0060] In step 1), the container is covered with a screen, and raw water is injected into the container from above the screen, so that the raw water is filtered through the screen, and the water entering the container is filtered water.

[0061]The raw water may be natural water or tap water, and in this embodiment, tap water is specifically used.

[0062] The mesh of the sieve is 200 mesh.

[0063] Step 2), put the water treatment agent into the filtered water, select the input amount of the water treatment agent according to the weight of the filtered water in the container, specifically, put 1kg of water treatment agent per ton of filtered water, rotate at 60r / min, stir for 5min, and mix well , to obtain treated water.

[0064] Step 3), continue to stir at 60r / min, and put a pH regulator into the treated water to adjust the pH value of the treated water to 8, then inject the treated water into...

Embodiment 2

[0067] A steam boiler water treatment method, comprising the following steps:

[0068] In step 1), the container is covered with a screen, and raw water is injected into the container from above the screen, so that the raw water is filtered through the screen, and the water entering the container is filtered water.

[0069] The raw water may be natural water or tap water, and in this embodiment, tap water is specifically used.

[0070] The mesh of the sieve is 230 mesh.

[0071] Step 2), put the water treatment agent into the filtered water, select the input amount of the water treatment agent according to the weight of the filtered water in the container, specifically, put 1kg of water treatment agent per ton of filtered water, rotate at 60r / min, stir for 5min, and mix well , to obtain treated water.

[0072] Step 3), continue to stir at 60r / min, and drop a pH regulator into the treated water to adjust the pH value of the treated water to 9, then inject the treated water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com