Preparation method of a multifunctional thermoelectric thin film power generation and light intensity sensor device

A technology of light intensity sensor and pyroelectric thin film, applied in the manufacture/processing of thermoelectric devices, thermoelectric devices that only use Peltier or Seebeck effect, etc., can solve the problems of little visible light detection, high absorption rate, and existence of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

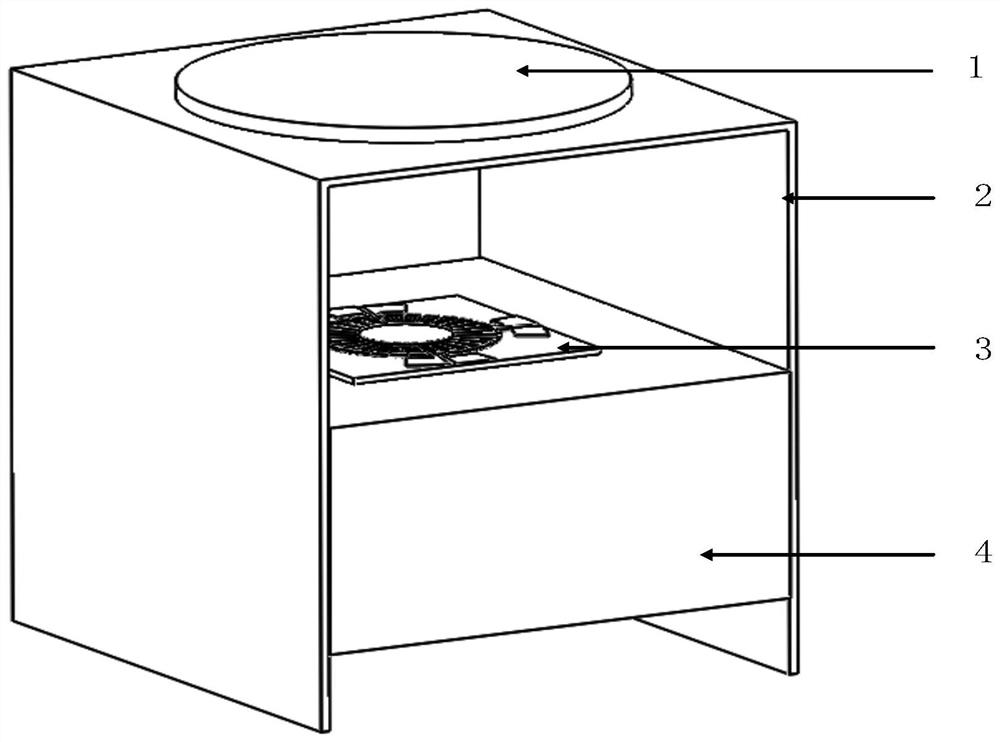

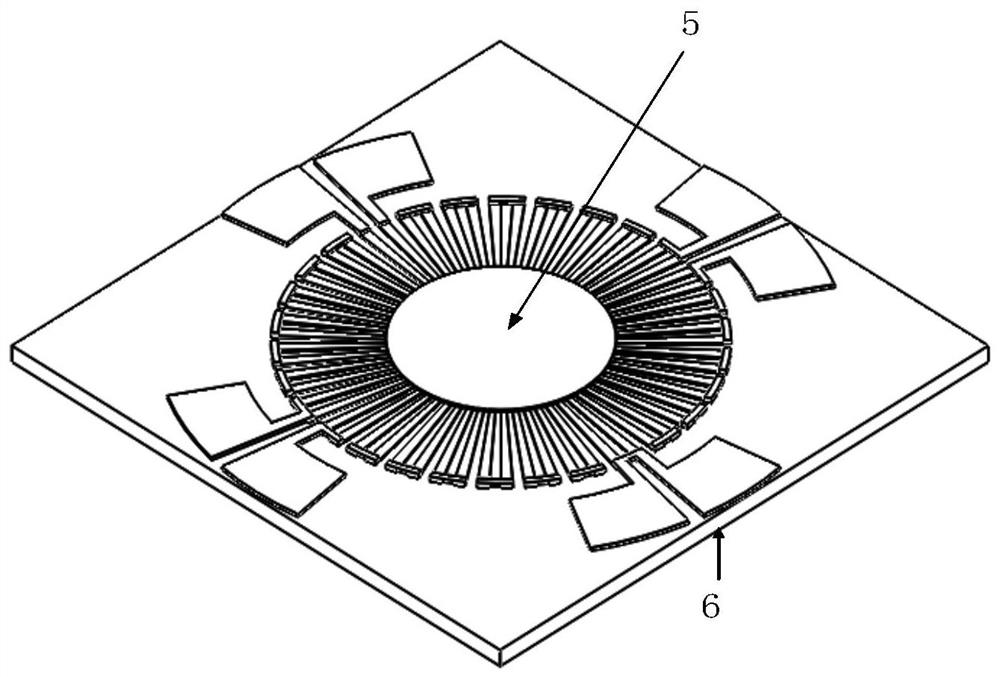

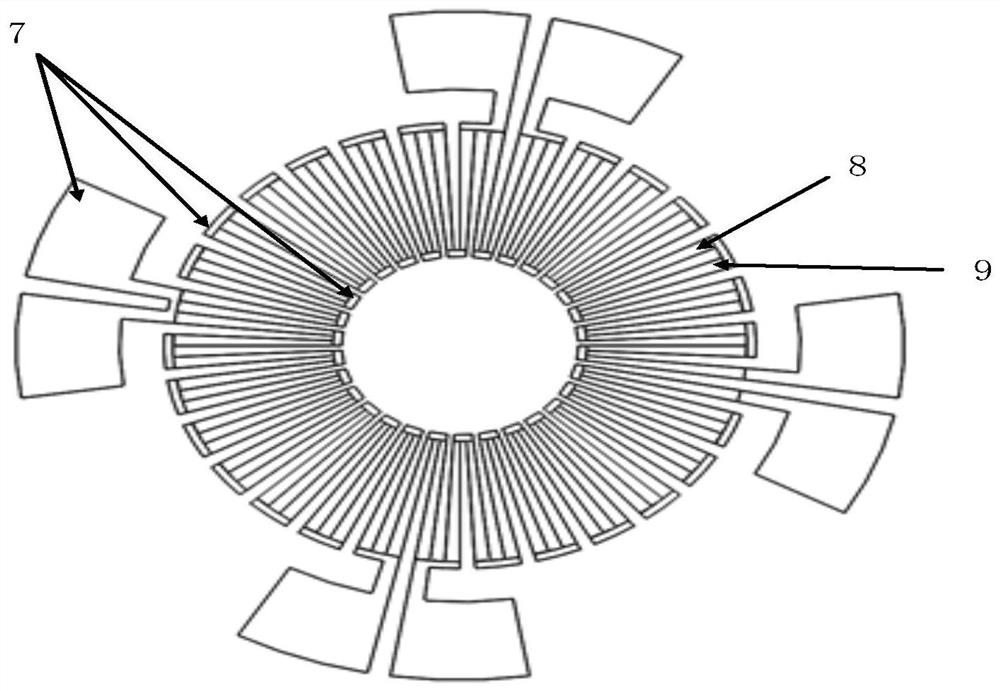

[0043]The invention provides a design and preparation method of a multi-functional high-density thermoelectric thin film power generation and light intensity sensor device, which utilizes the carrier transport inside the solid thermoelectric material to realize mutual conversion of heat energy and electric energy, and is compatible with development by designing high-density thermoelectric thin film devices. The method of permanent micromachining preparation greatly improves the power output, light intensity response and reliability of the device, so as to carry out environmental heat energy collection and active light intensity sensing, and realize the dual functions of thermoelectric power generation and signal sensing. The prepared thermoelectric Thin film power generation and light intensity sensor devices have high output voltage, high responsivity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com