Essence and fragrance for tobacco, cigarette paper containing the essence and fragrance for tobacco and application thereof

A technology for tobacco flavor and cigarette paper, which is applied in the directions of essential oil/spice, application, tobacco, etc., to achieve the effects of reduced irritation, good stability, clean and comfortable aftertaste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] Example 1 Production of cigarette paper A1

[0109] 1) The Tieguanyin tea (finished product) is dried, powdered, and extracted twice with pure water at room temperature, and the material-liquid ratio of each immersion is 1:20 (g / g), and the extract obtained by two dips is combined. The extract is filtered through a 100 nm microfiltration membrane to collect the filtrate, and then the filtrate is filtered through a 10Dal ultrafiltration membrane to collect the permeable solution. Concentrate the permeable liquid to 1 / 20 of the original volume, which is the Tieguanyin tea extract.

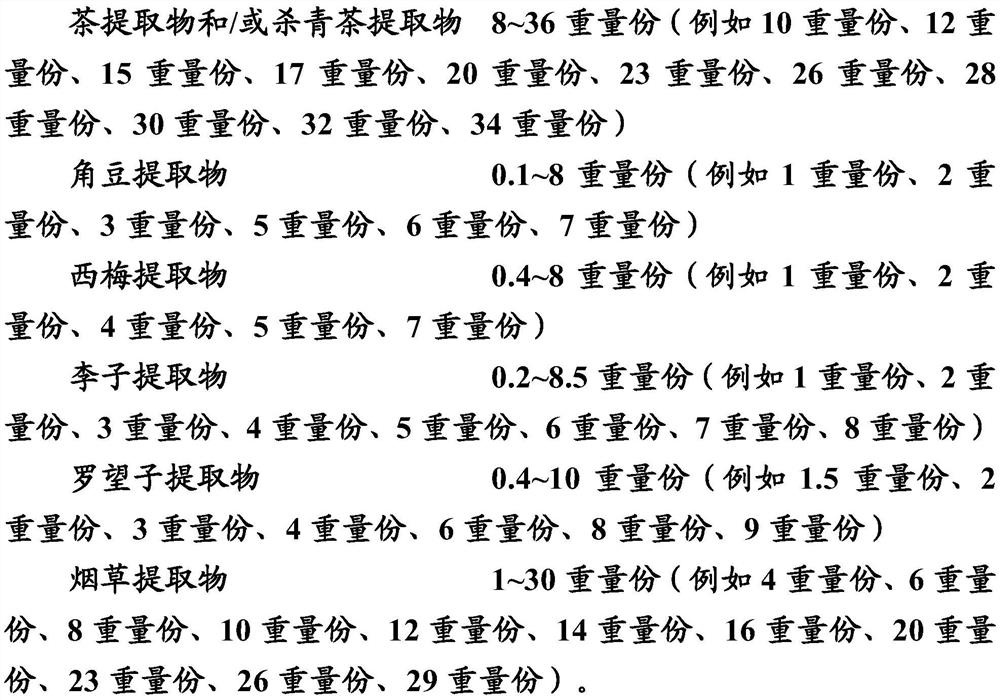

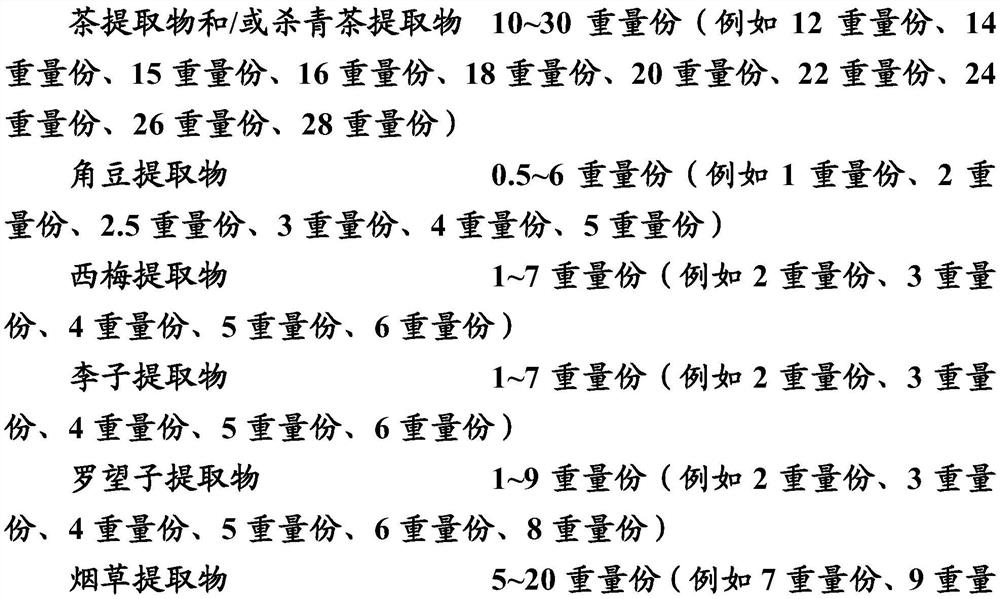

[0110] 2) Tieguanyin tea extract, prune extract, plum extract, carob extract, tamarind extract, tobacco extract and propylene glycol are mixed evenly according to the mass ratio in Table 1 to obtain tobacco flavor A1.

[0111] 3) In the sizing process, the cigarette flavor and fragrance A1 is formulated into a solution sprayed to the surface of the paper, and after drying, it is prepared into ci...

Embodiment 2

[0114] Example 2 Production of cigarette paper A2

[0115] 1) Preparation of Tieguanyin Qingqing Tea:

[0116] Tieguanyin tea green after withering, green and killing, to obtain Tieguanyin green tea. thereinto

[0117] Withering treatment: Tieguanyin tea green is evenly spread out in a cool and ventilated place, the drying temperature is 30 ° C, until the leaf surface loses luster, the leaves are soft, and the top of the leaf at the bottom of the leaf is sagging, and the withered tea green is obtained.

[0118] Do green treatment: put the withered tea green into the shaking machine for shaking green treatment, the amount of tea green added is half of the volume of the shaking machine, the speed of the shaking machine is 30r / min, the temperature of the shaking is 22 °C, and the drying temperature is 18 °C. The first shaking time is 10 minutes, the tea green after shaking the green is spread out on the drying rack to dry, the second shaking time is 30 minutes after drying for 1 hou...

Embodiment 3

[0124] Example 3 Manufacture of cigarette S1 ~ S2

[0125] Take brand tobacco 1, use cigarette paper A1 ~ A2, blank cigarette paper (no cigarette flavor and fragrance is added in the sizing process) to make cigarette S1 ~ S2, S0 according to the conventional method. The quality of brand tobacco 1 in each cigarette S1 to S2 and S0 is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com