3D glass hot bending machine and 3D glass forming method

A glass and 3D technology, applied in the field of 3D glass forming, can solve the problems of poor hot bending surface quality, high mold surface, slow hot bending speed, etc., and achieve good hot bending surface quality, high processing quality and fast hot bending speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

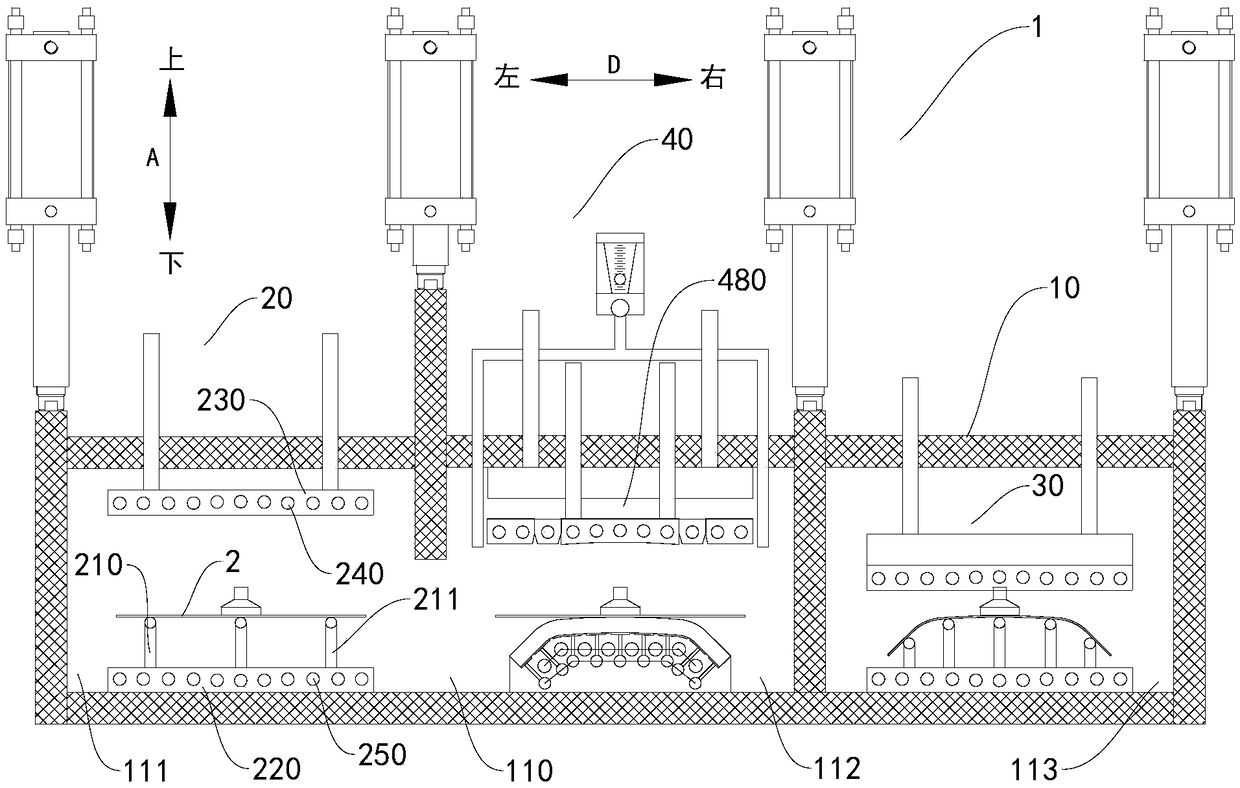

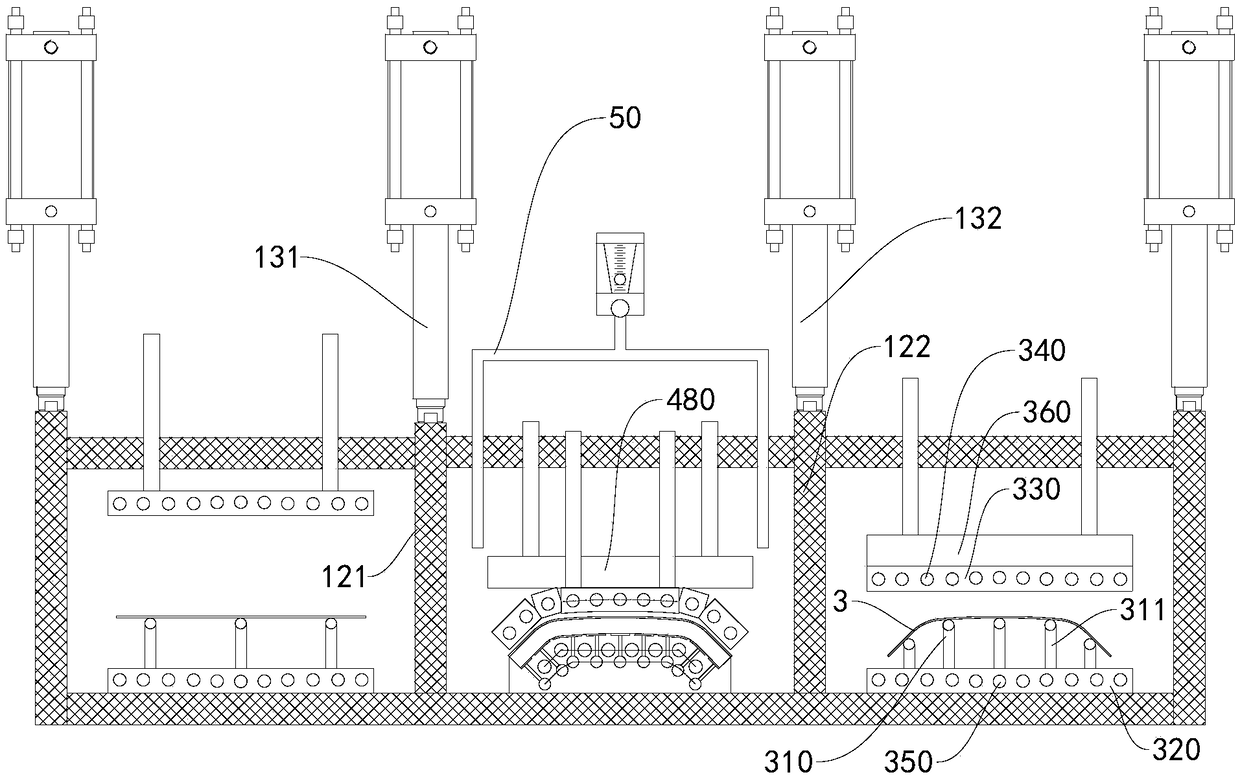

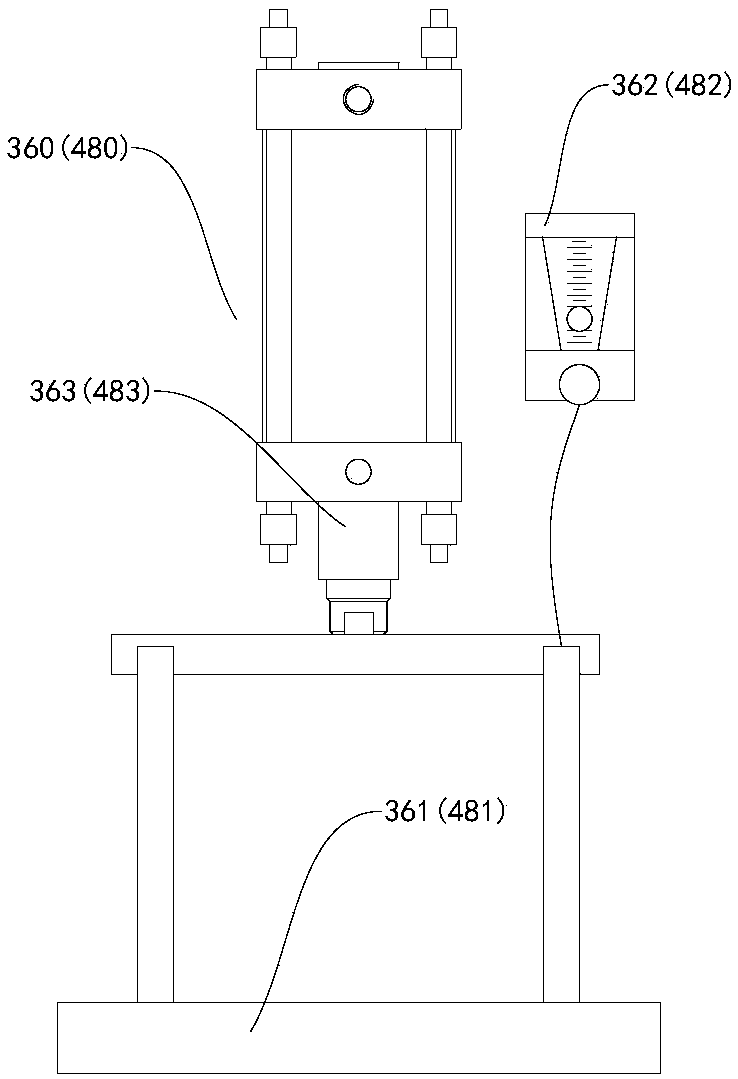

[0041] A 3D glass bending machine 1 according to an embodiment of the present invention will be described below with reference to the accompanying drawings. Such as Figure 1-Figure 14 As shown, the 3D glass bending machine 1 according to the embodiment of the present invention includes a furnace body 10 , a first partition 121 , a second partition 122 , a preheating device 20 , an annealing device 30 and a 3D glass bending device 40 .

[0042] The furnace body 10 has an accommodating chamber 110 , and a first partition 121 and a second partition 122 are spaced apart in the accommodating chamber 110 and divide the accommodating chamber 110 into a preheating cham...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com