Coaxial butt-joint tool of two sections of high-precision steel tubes in long-short ratio of being greater than 9

A high-precision, length-to-length ratio technology, applied in the field of coaxial butt joint tooling of two high-precision steel pipes, can solve the problems of low precision, small axial length, and difficulty in finding small deflection angles, so as to avoid random errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with drawings and embodiments.

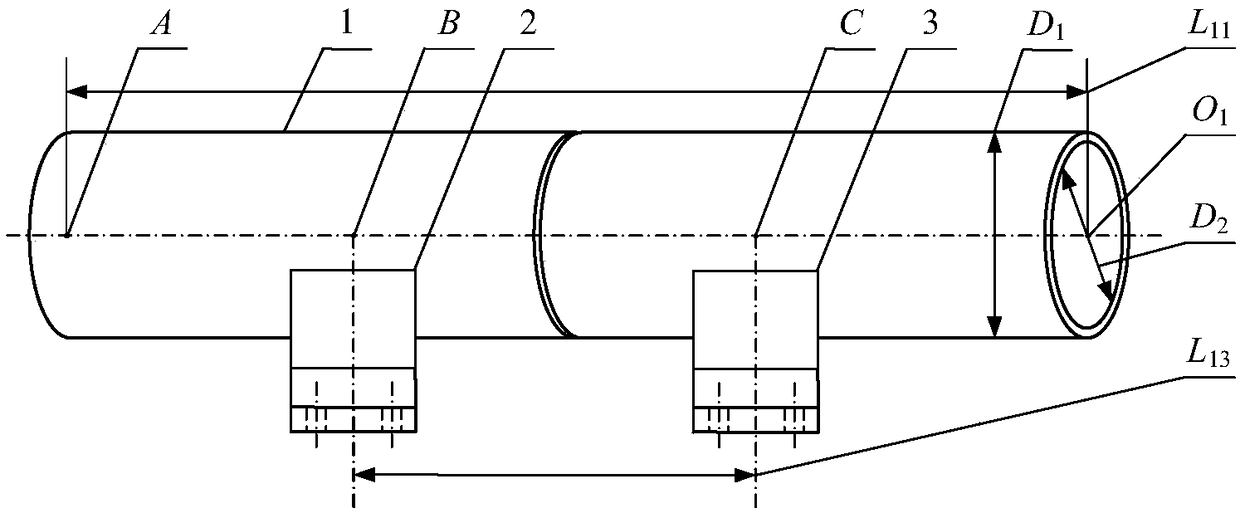

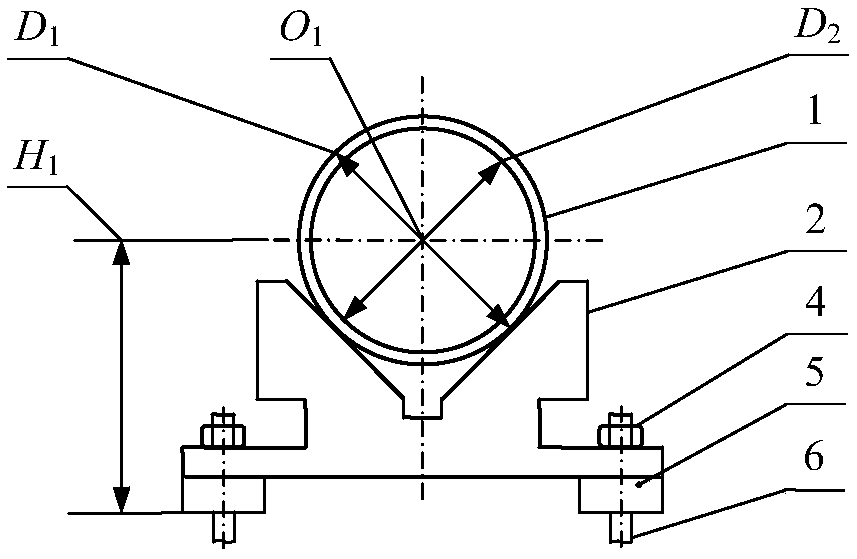

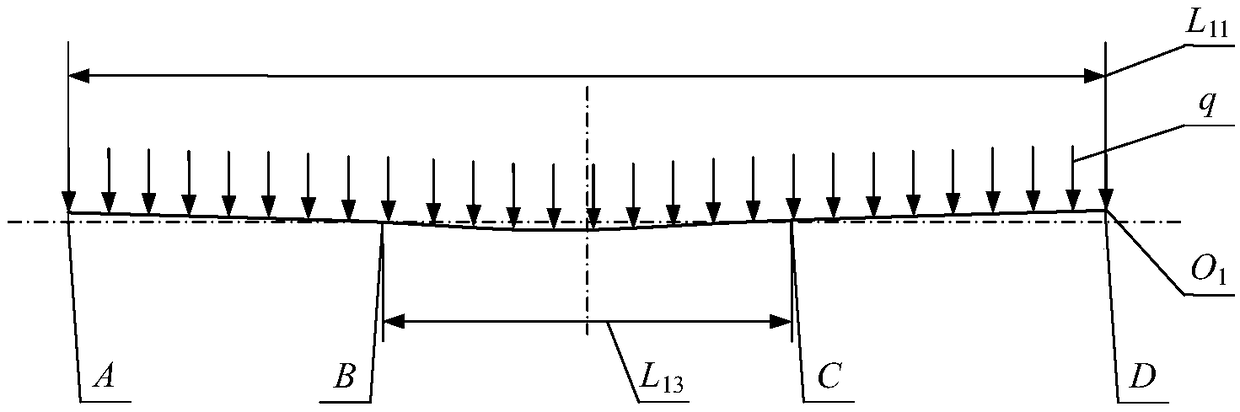

[0064] like Figure 1 to Figure 3 The structure diagram of the long steel pipe and two V-shaped support blocks shown, the long steel pipe 1 is placed on the left V-shaped support block 2, the right V-shaped support block 3, the left V-shaped support block 2, the right V-shaped support block The support block 3 is fixed on the foundation 7 by anchor screws 6, nuts 4, and anchor pads 5.

[0065] The outer diameter of the long steel pipe 1 is D 1 , the inner diameter is D 2 , the length of the long steel pipe 1 is L 11 , the fulcrum length of the two V-shaped support blocks of the long steel pipe 1 is L 13 , the left end point on the long steel pipe 1 axis is A, the intersection point of the left support middle section and the long steel pipe 1 axis is B, the intersection point of the right support middle section and the long steel pipe 1 axis is C, and the right end p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com