Metering pump flow control method based on networked generalized predictive control optimization

A generalized predictive control and flow control technology, applied in the field of metering pumps, can solve problems such as difficult to achieve high-performance control, prone to integral saturation, and weak robustness, and achieve good tracking performance and anti-interference performance. The effect of responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

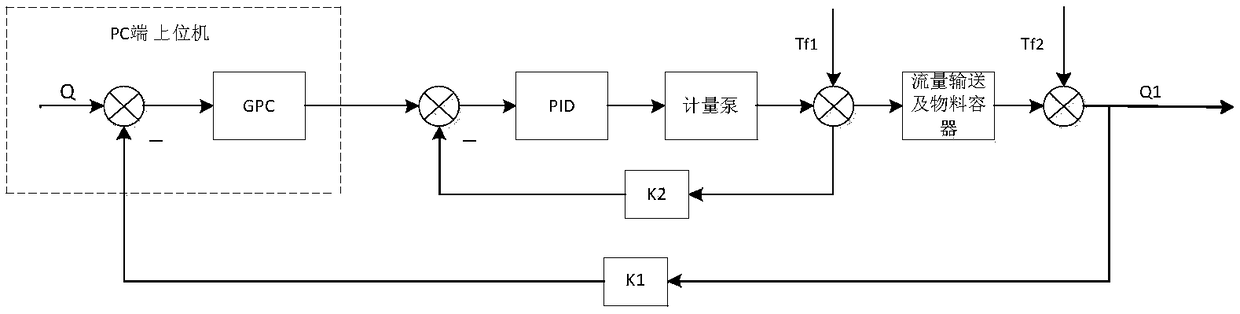

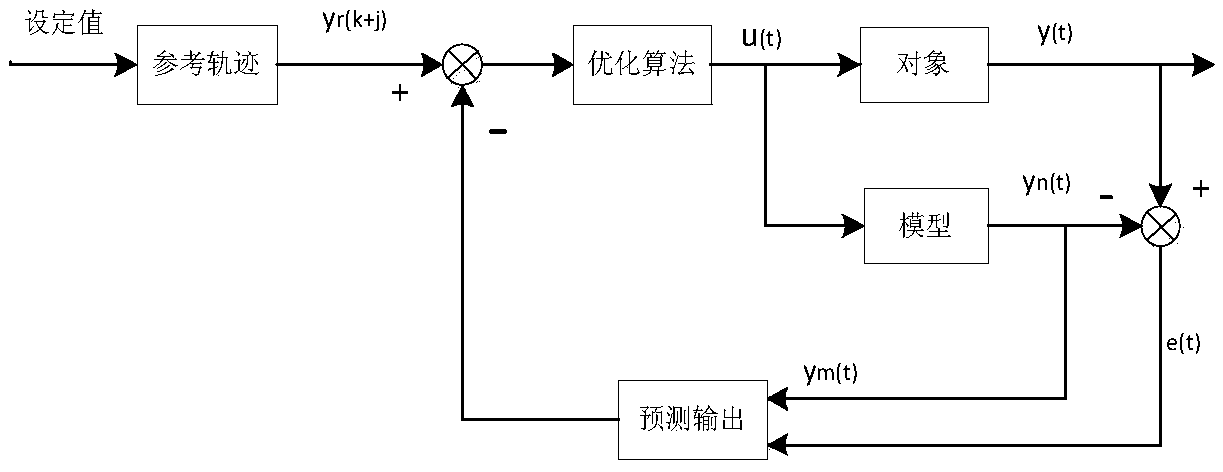

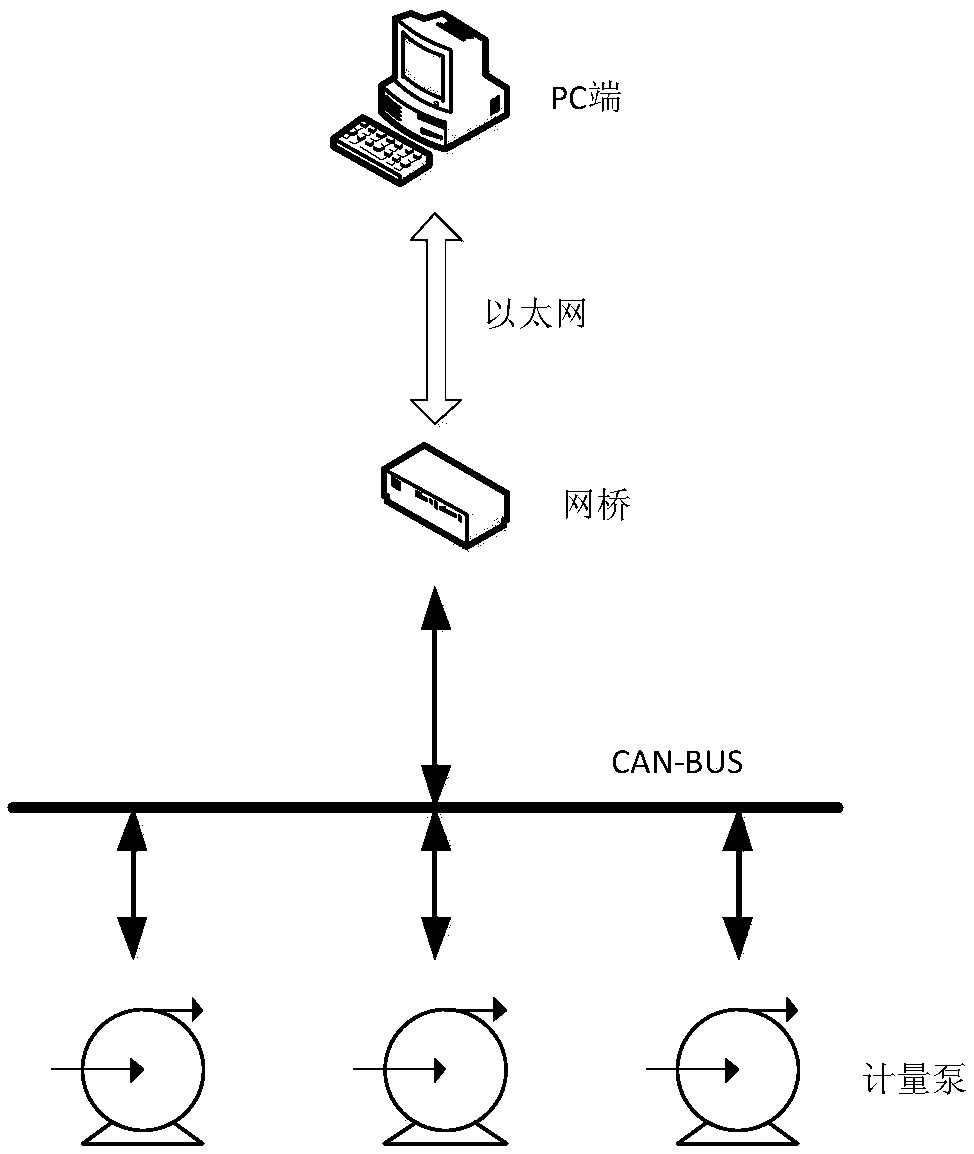

[0045] refer to Figure 1 ~ Figure 2 , the GPC control loop is introduced into the traditional single-loop feedback control system, combined with PID control to form a GPC-PID flow cascade control system, and a networked control method is adopted.

[0046] Taking the diaphragm metering pump as an example to analyze its system structure, it can be seen that the metering pump is driven by the motor, and the diaphragm is concave and convex through the reduction device and the transmission mechanism to form a pressure difference to realize the inflow and outflow of fluid. The entire metering pump system can be decomposed into the motor control system part and the flow output and detection control system part. The motor system is used as the inner loop control object, and the remaining parts form the outer loop control object.

[0047] The control mode of the inner loop sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com