Spinning rotor for an open-end spinning machine having a friction-enhancing lining made of an elastomeric material, and open-end spinning machine

A technology of increasing friction and free end, applied in the direction of free end spinning machine, continuous winding spinning machine, spinning machine, etc., can solve the problems of large energy consumption and increased bending work in the rotor support area, and achieve favorable Effects of vibration damping performance, reduced slippage, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

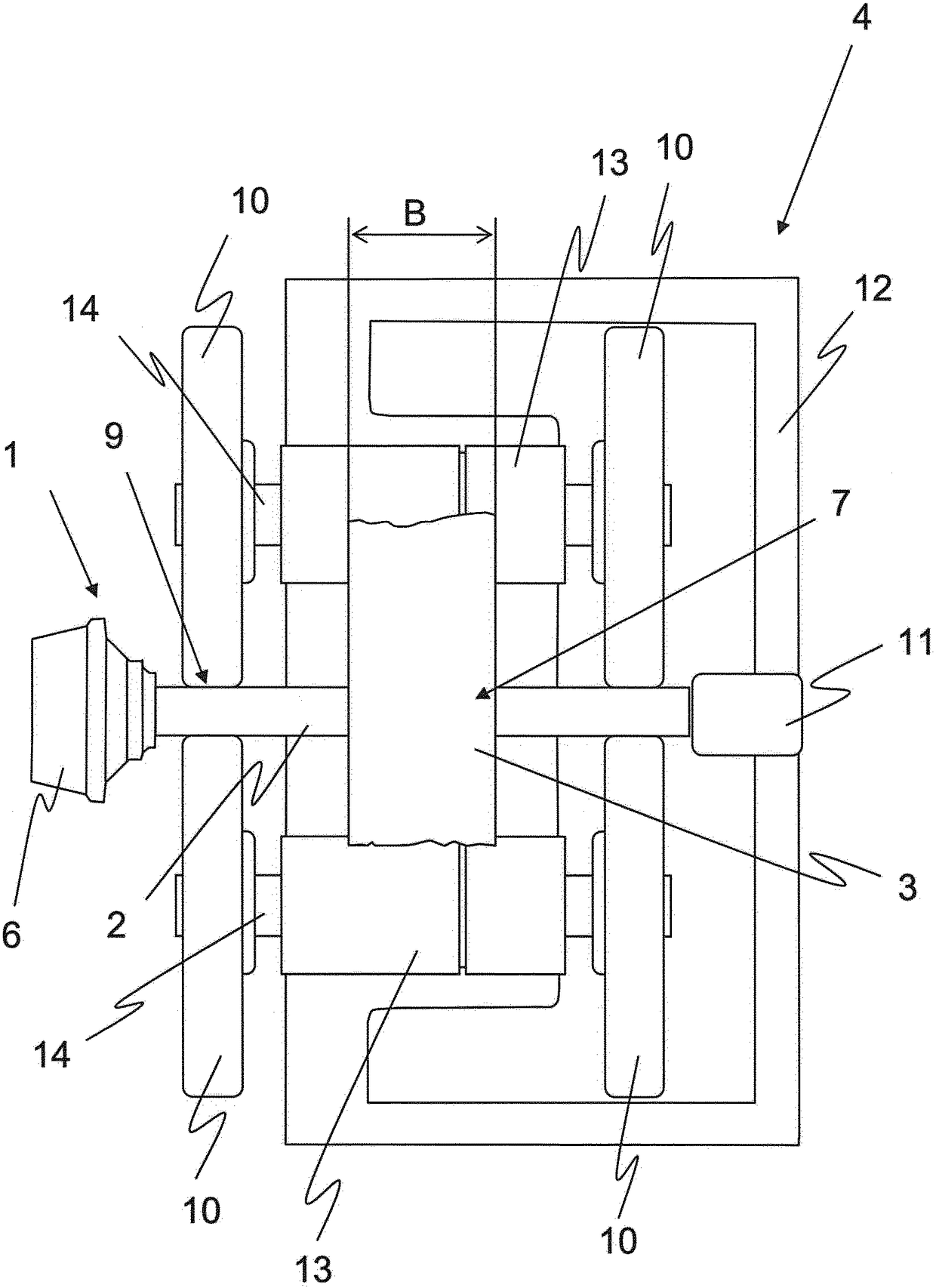

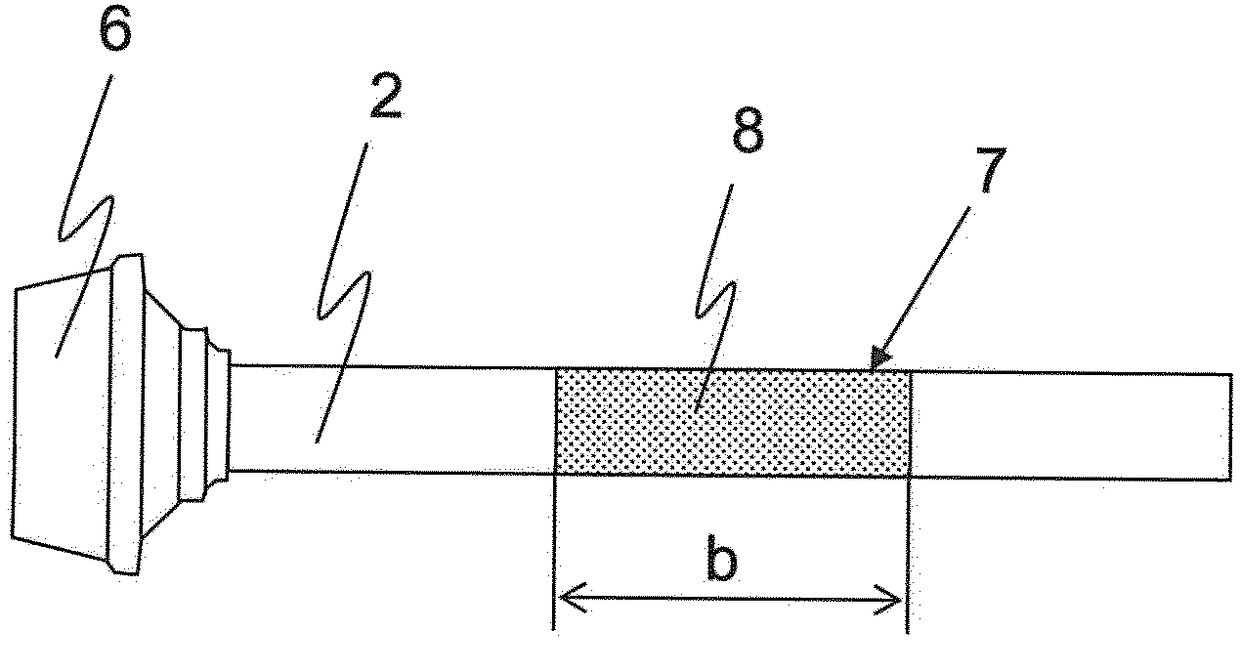

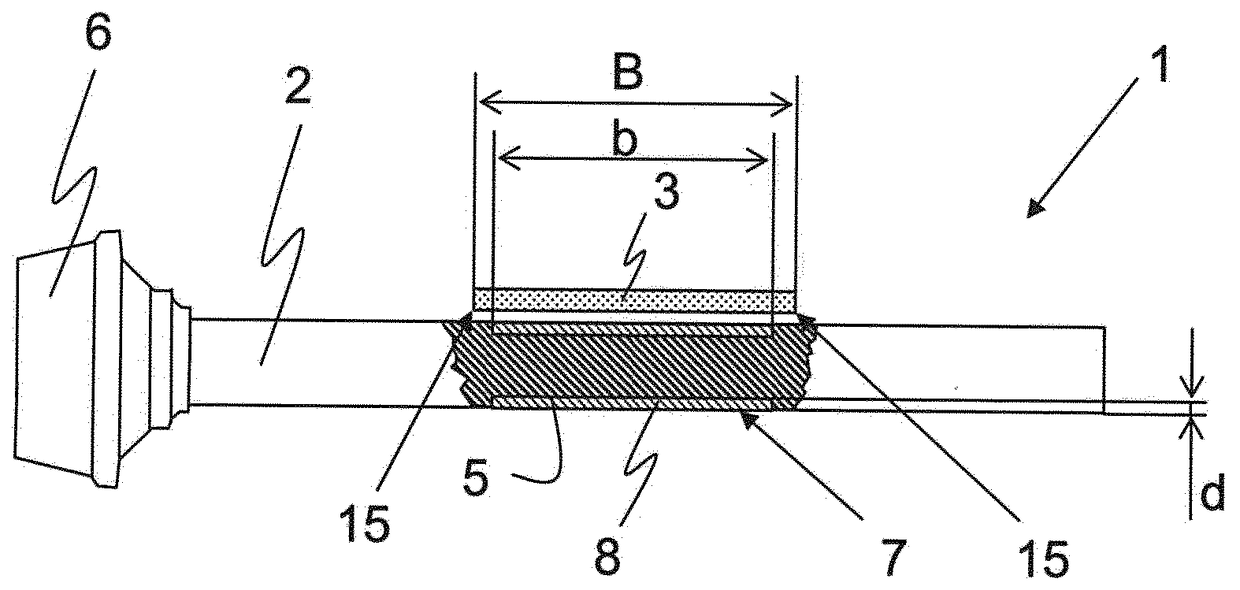

[0021] figure 1 An open-end spinning device 4 with a spinning rotor 1 and a belt 3 for driving the spinning rotor 1 is shown in a schematic plan view. The spinning rotor 1 generally consists of a rotor shaft 2 and a rotor cup 6 , which can be detachable or fixedly connected to the rotor shaft 2 . The spinning device 4 comprises a conventional bearing arrangement for the spinning rotor 1 , which in the present example is designed in the form of a support disc bearing. In this case, for the radial support of the spinning rotor, two support disk bearings 13 are accommodated in a bearing seat 12 in which in turn a shaft 14 is supported in each case. In this case, each of the two shafts 14 carries a support disk 10 at its two ends. The two shafts 14 with the support disks 10 are now arranged in such a way that between each two support disks 10 a wedge-shaped gap 9 is formed in which the spinning rotor 1 can be accommodated with its rotor shaft 2 . Between the two thus formed pai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com