In-line hydraulic crimp tool

A technology for crimping tools and tools, applied in the field of hydraulic tools, can solve the problems of jaw casting defects, uneven cooling of metals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] While the present invention will be shown and described in connection with a battery powered hand-held docking tool, those of ordinary skill in the art will readily appreciate that the inventive concepts and aspects of the present invention can be implemented in a variety of tools, fields and applications. The invention should not be considered limited to the embodiments described herein.

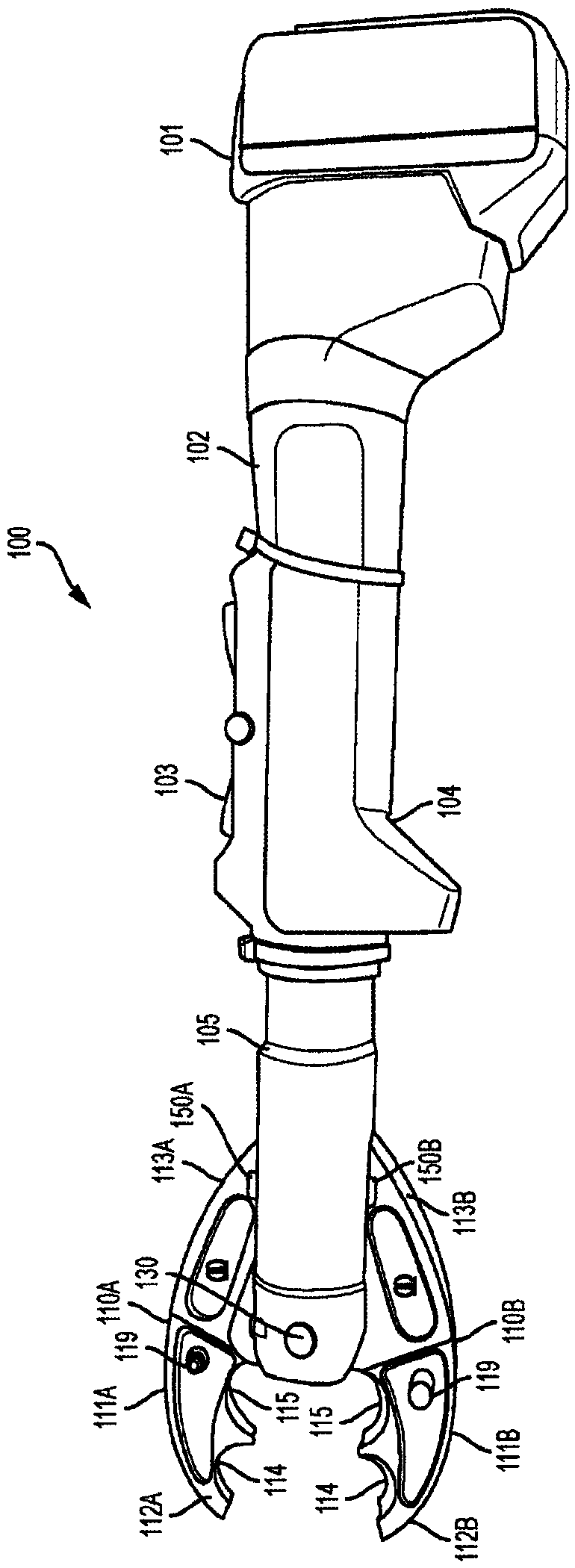

[0037] Such as figure 1 As shown, the battery powered crimping tool 100 includes a battery pack 101 , a handle portion 102 housing a control 103 and a handle 104 , a neck 105 and a pair of cooperating jaw members 110A, 110B.

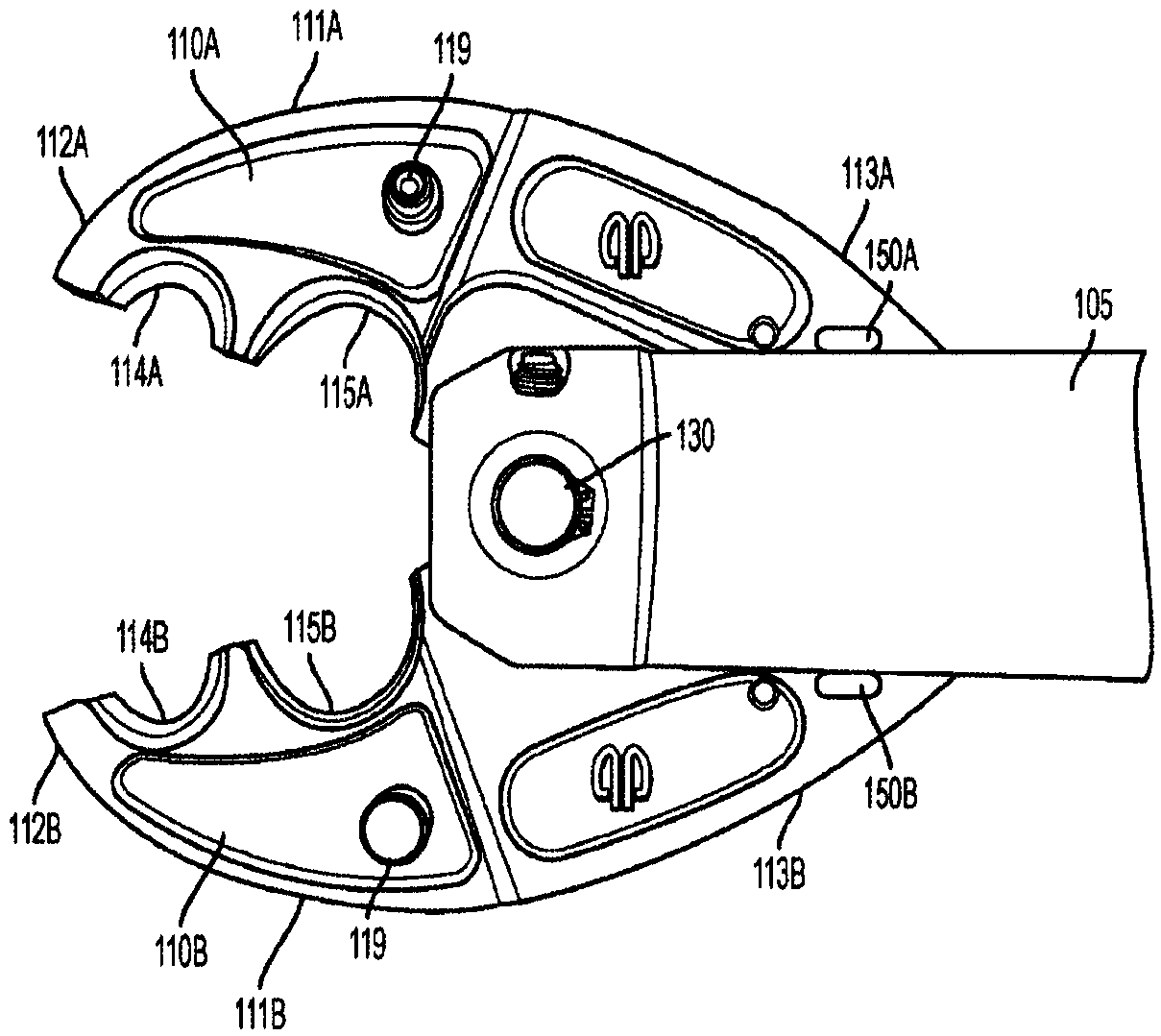

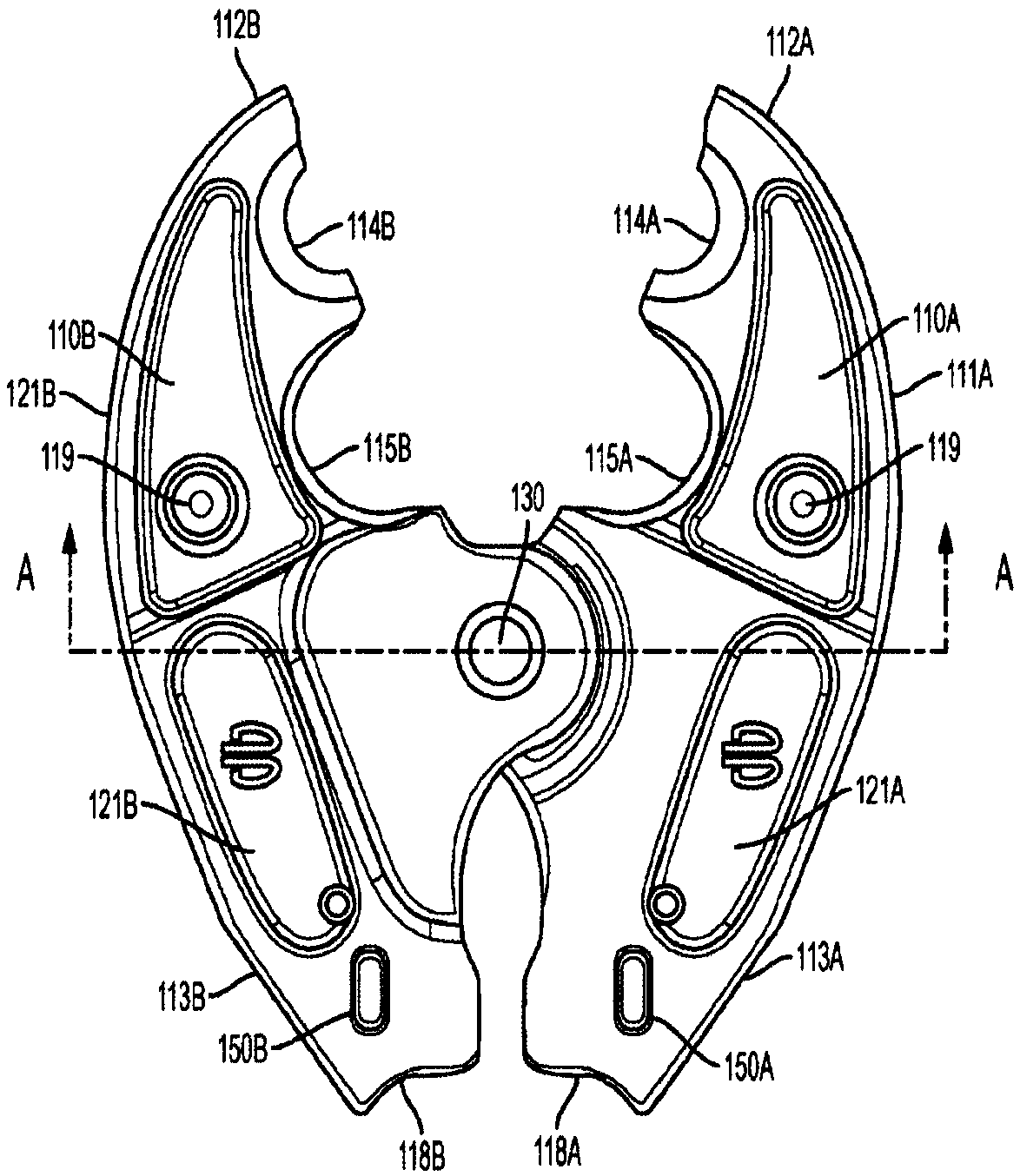

[0038] Such as figure 2 As best shown in 3 and 3, each jaw member includes a curved compression rod 111 having a front tip portion 112 and a rear portion 113. The inner region of the jaw rod defines one or more curved crimping surfaces 114 , 115 . In the illustrated embodiment, the jaws include crimping grooves 114,115. As understood by those of ordinary s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com