Method for laying a High-voltage large-section cable to fit the width

A cable line and width adjustment technology, applied in cable laying equipment and other directions, can solve the problems of lack of fulcrum and inability to realize the erection of radius type I-frames, and achieve the effect of ensuring escape safety and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

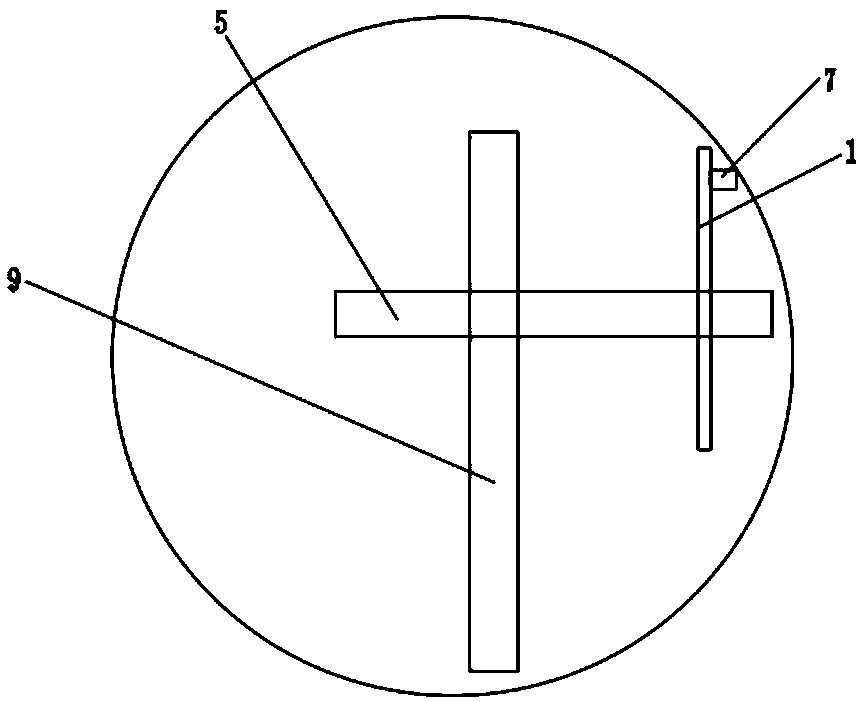

[0023] The present invention will be further described below in conjunction with specific drawings.

[0024] According to the present invention, the laying method of high-voltage and large-section cable line with adjustable width can include the following steps:

[0025] First, set up cable supports and scaffolding in the channel where cables need to be laid according to the requirements of the construction layout plan;

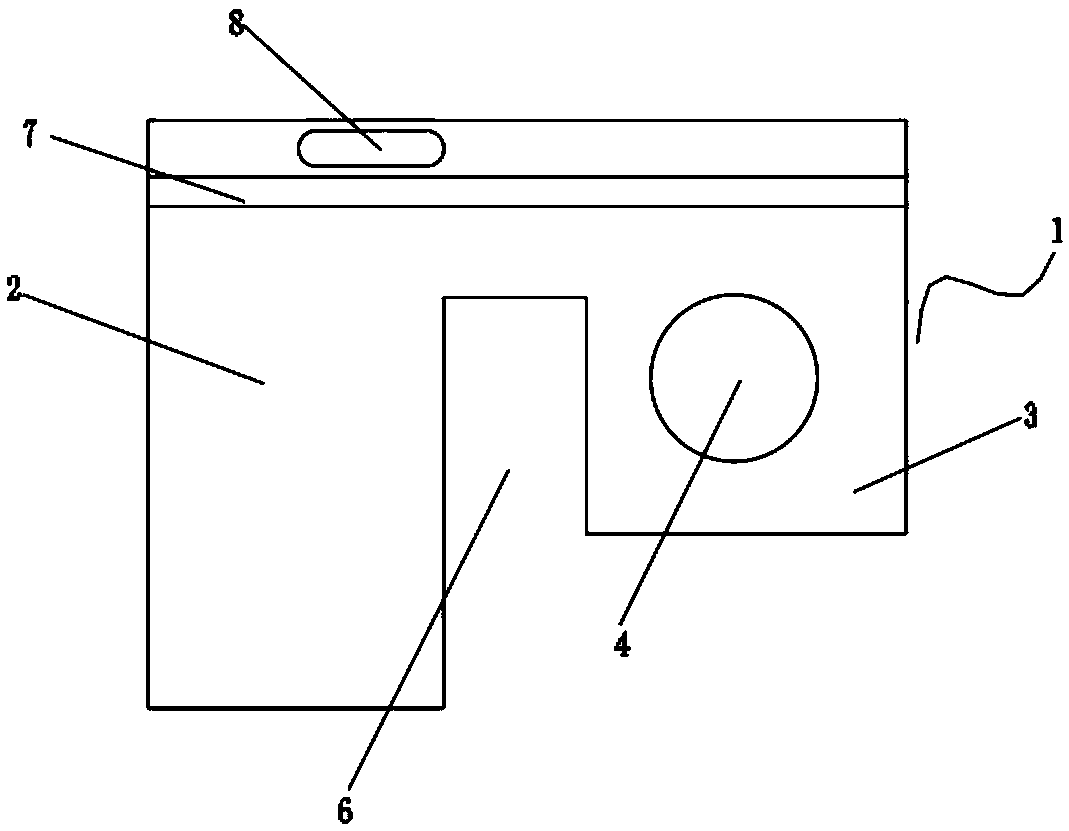

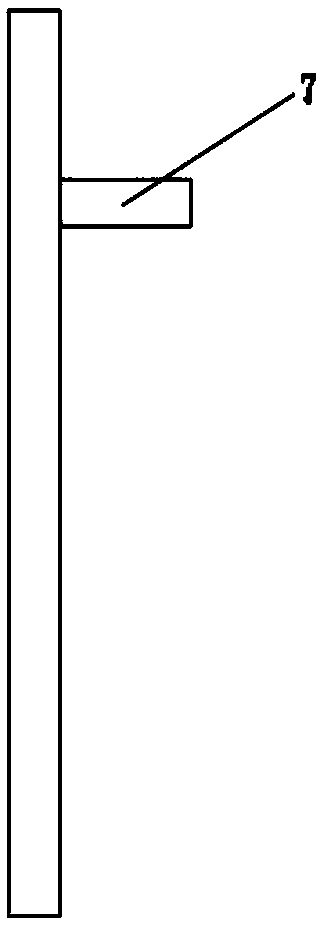

[0026] Next, insert the insertion part 2 of the plug-in type fixing device into the inner side of the cable bracket; the plug-in type fixing device includes a plug-in body 1, one side of the plug-in body 1 is the insertion part 2, and the other side The side is the installation part 3, the insertion part 2 is used to insert the inner side of the cable bracket, and the installation part 3 is provided with a screw back fixing hole 4. There is a distance 6 between the parts 3, and the distance 6 is generally consistent with the thickness of the side part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com