A method for manufacturing a corner-type shield ring for a gas insulate metal-enclosed switch

A gas-insulated metal, closed switch technology, used in switchgear, electrical components, substation/distribution device casings, etc., can solve the problems of prolonged product manufacturing cycle, no profit space for enterprises, long mold opening cycle, etc., and achieve manufacturing costs. Low, ensuring on-time delivery and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

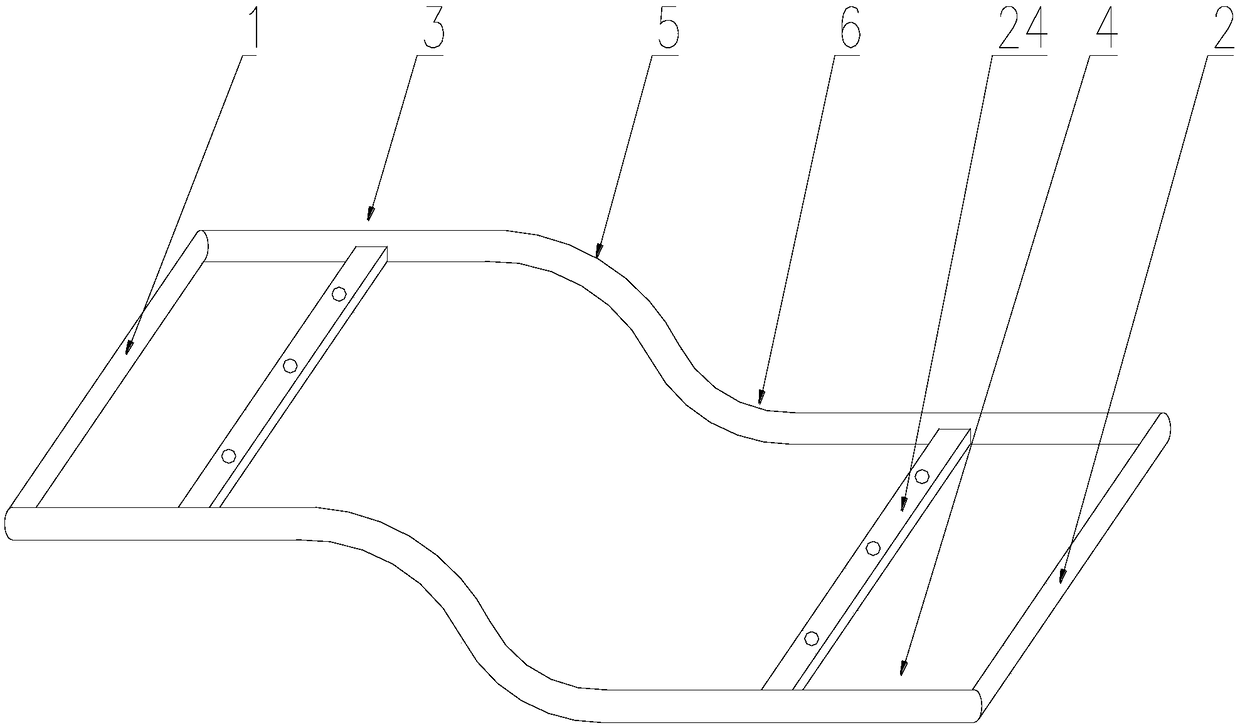

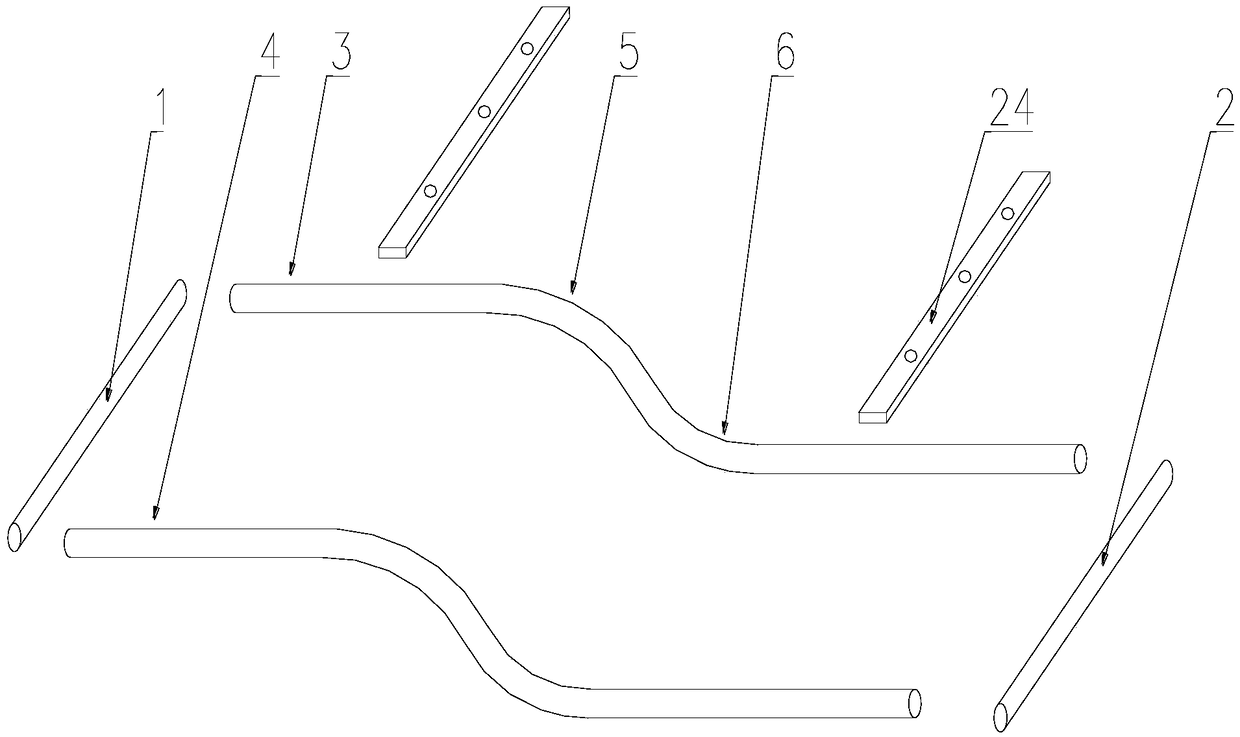

[0083] A method for manufacturing a corner-type shielding ring for a gas-insulated metal-enclosed switch,

[0084] a. Preparation before processing; two pairs of metal pipes and two mounting plates 24 with pre-opened threaded mounting holes are prepared in advance; one pair of A1 and A2 pipes of the two pairs of metal pipes is used to process the left pipe 1 of the shielding ring , the right side tube 2, and another pair of B1 and B2 tubes are used to process the upper side tube 3 and the lower side tube 4;

[0085] b. Process the upper side pipe; use special processing tooling to process the first-level corner and the second-level corner of the B1 pipe, and the processed corner-shaped elbow is both the upper side pipe;

[0086] c. Process the lower side pipe; use special processing tooling to process the first-level corner and the second-level corner of the B2 pipe, and the processed corner-type elbow is both the lower side pipe;

[0087] d. Welding the left side pipe; After...

Embodiment 2

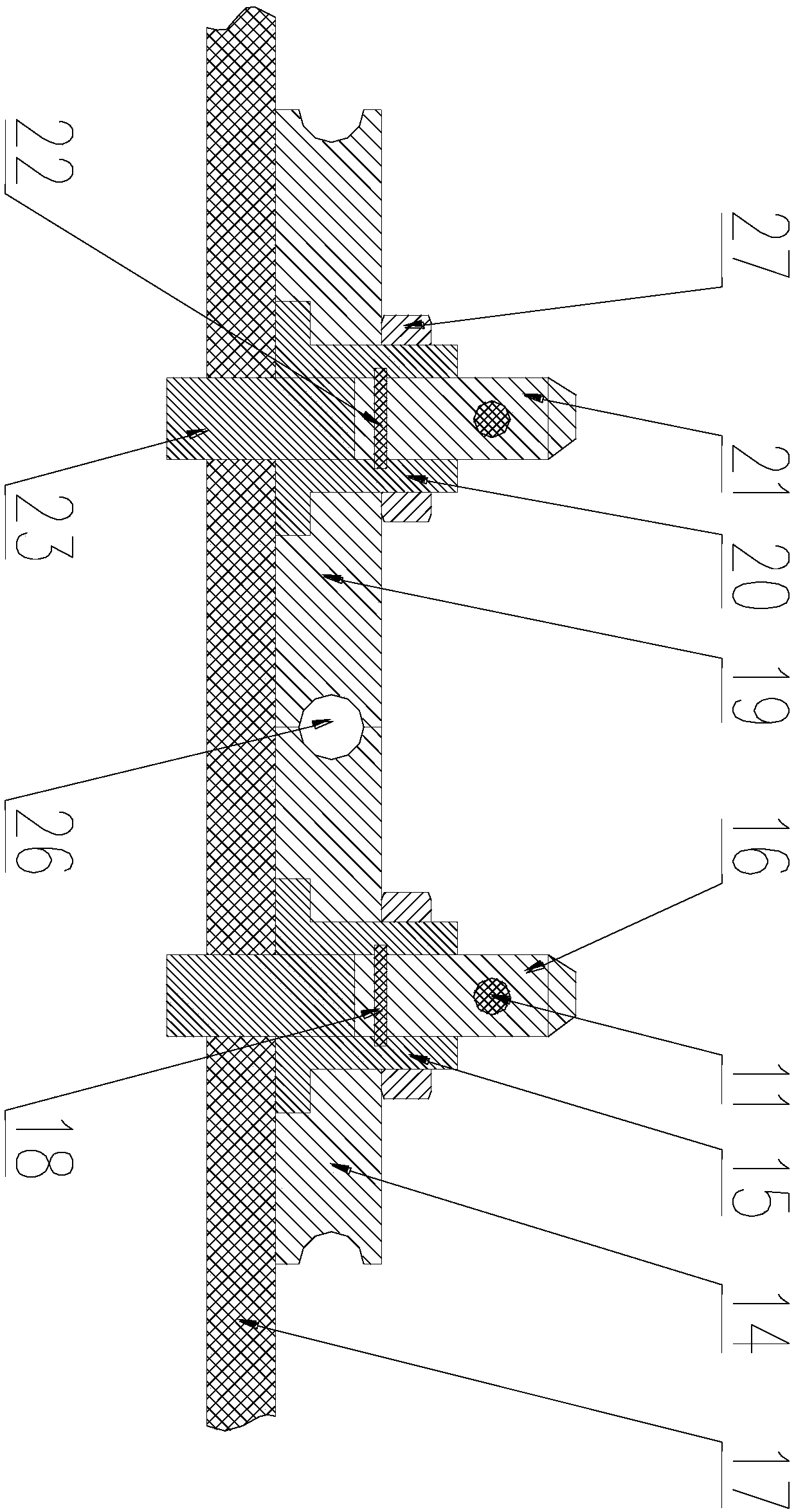

[0101] In this embodiment, on the basis of Example 1, the lower half of mandrel I16 and mandrel II21 are both milled into a racetrack-shaped flat rod body 23; The groove width of groove 8, the narrow face width of the flat rod body of mandrel II 21 is less than the groove width of big roller disc movement chute 7. The inner diameter of positioning hole I9, the inner diameter of positioning hole II10 are greater than or equal to the outer diameter of mandrel I16, and are also greater than the groove width of the small roller movement chute 8; the inner diameter of positioning hole III12, and the inner diameter of positioning hole IV13 are greater than or equal to the outer diameter of mandrel II21 , is also greater than the groove width of the large roller disc movement chute 7. The arc trajectory of the small roller disk movement chute 8 is concentric with the large roller disk 19; the arc trajectory of the large roller disk movement chute 7 and the small roller disk 14 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com