A modification method of lithium titanate negative electrode material for lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of increased electrode/electrolyte interface impedance, affecting the application of lithium titanate, and decreasing rate performance, etc., to achieve reversible capacity and Improved cycle performance, reduced charge transfer resistance, and reduced polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

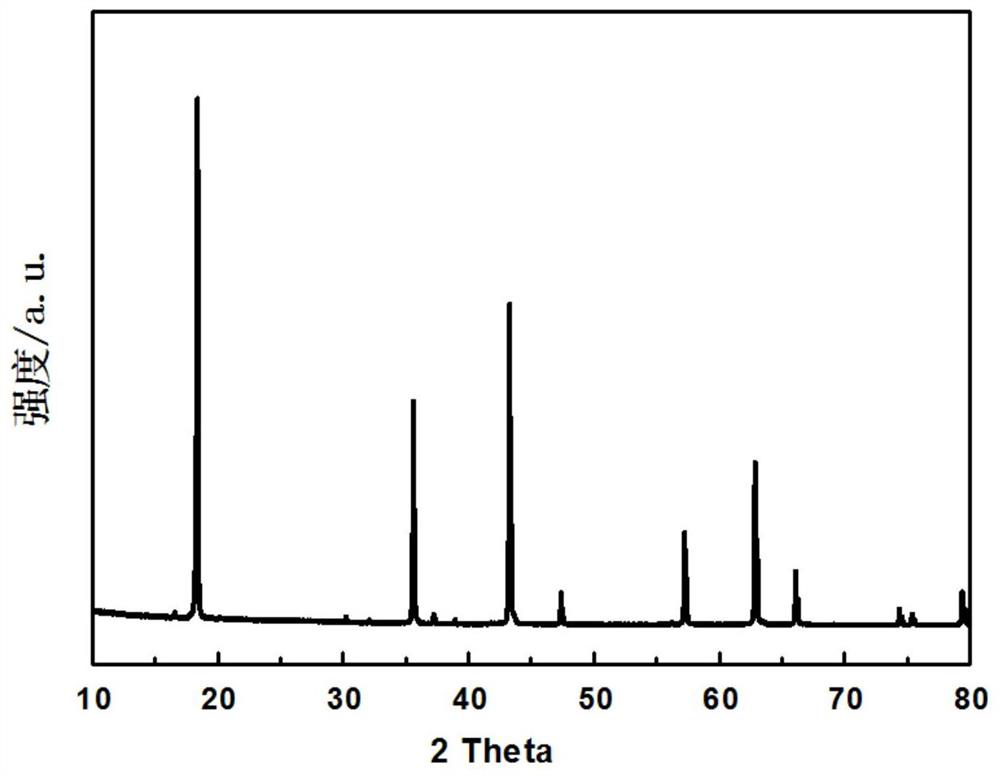

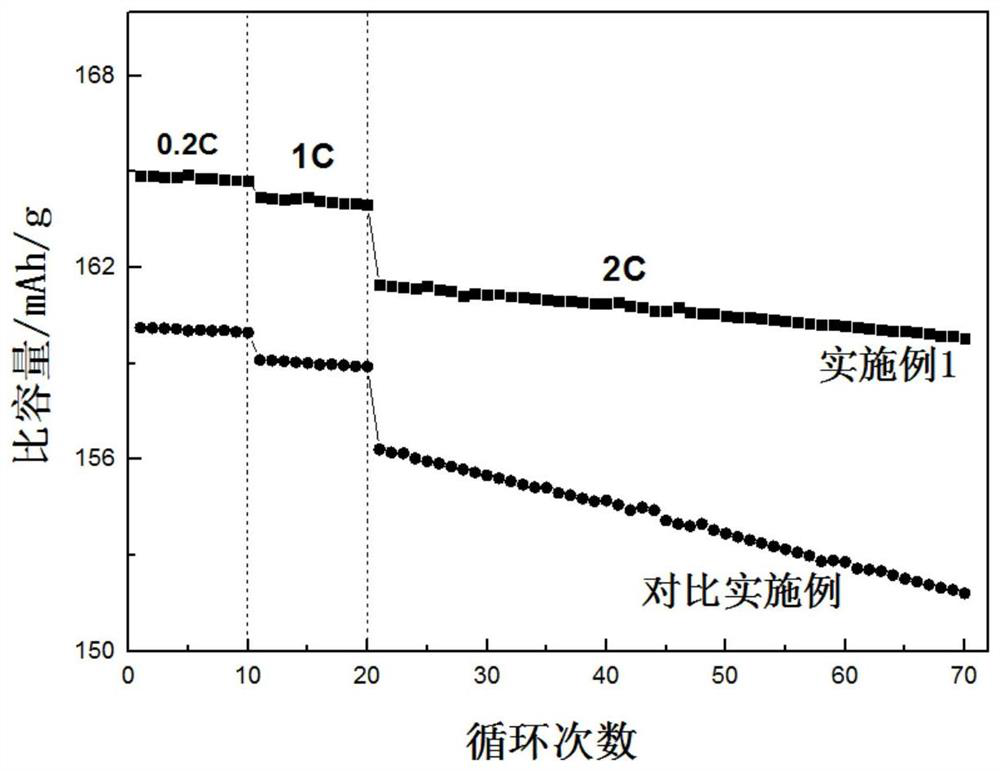

Image

Examples

Embodiment 1

[0030] A method for modifying a lithium titanate negative electrode material for a lithium ion battery, specifically comprising the following steps:

[0031] (1) After smoothing the pure titanium sheet with sandpaper, ultrasonically clean it with acetone, absolute ethanol and deionized water in sequence, and then put it into the HCL solution with a molar concentration of 6mol / L at normal temperature and pressure for 10h Then take it out, wash it with deionized water until the pH value is 6, put it into a drying oven, dry it at 80°C for 1 hour, and calcinate it at 350°C for 3 hours to obtain a titanium dioxide film;

[0032] (2), add ethylenediaminetetraacetic acid chelating agent in the dehydrated ethanol solution containing lithium hydroxide, stir 2h in water bath at 60 ℃, obtain sol; Wherein, the molar concentration of lithium hydroxide is 0.1mol / L, B The mass concentration of diamine tetraacetic acid is 1%;

[0033] (3) Immerse the titanium dioxide film obtained in step (1) ...

Embodiment 2

[0039] A method for modifying a lithium titanate negative electrode material for a lithium ion battery, specifically comprising the following steps:

[0040] (1) After smoothing the pure titanium sheet with sandpaper, ultrasonically clean it with acetone, absolute ethanol and deionized water in sequence, and then put it into the HCL solution with a molar concentration of 8mol / L at normal temperature and pressure for 15 hours. Then take it out, then wash it with deionized water until the pH value is 7, and finally put it in a drying oven at 90°C for 5 hours, and then calcinate at 450°C for 4 hours to obtain a titanium dioxide film;

[0041] (2), add oxalic acid chelating agent in the dehydrated ethanol solution containing lithium acetate, stir in water bath at 70 ℃ for 6h, obtain sol; Wherein, the molar concentration of lithium acetate is 1.5mol / L, the mass concentration of oxalic acid is 5% ;

[0042] (3) Immerse the titanium dioxide film obtained in step (1) into the sol obt...

Embodiment 3

[0048] A method for modifying a lithium titanate negative electrode material for a lithium ion battery, specifically comprising the following steps:

[0049] (1) After smoothing the pure titanium sheet with sandpaper, ultrasonically clean it with acetone, absolute ethanol and deionized water in sequence, and then put it into the HCL solution with a molar concentration of 10mol / L at normal temperature and pressure for 25 hours. Then take it out, wash it with deionized water until the pH value is 7.5, put it in a drying oven, dry it at 100°C for 8 hours, and calcinate it at 600°C for 4 hours to obtain a titanium dioxide film;

[0050] (2), add citric acid chelating agent in the dehydrated ethanol solution containing lithium nitrate, stir 12h in water bath at 80 ℃, obtain sol; Wherein, the molar concentration of lithium nitrate is 3mol / L, and the mass concentration of citric acid is 15 %;

[0051] (3) Immerse the titanium dioxide film obtained in step (1) into the sol obtained i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com