An LED condensing light source and an exposure light source system using the LED condensing light source

A light source system and LED lamp bead technology, which is applied in microlithography exposure equipment, photolithography exposure devices, optics, etc., can solve the problems of inconsistent parallel half angles, poor product quality consistency, low production efficiency, etc., and achieve parallel half angle consistency , Improve exposure efficiency, good uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

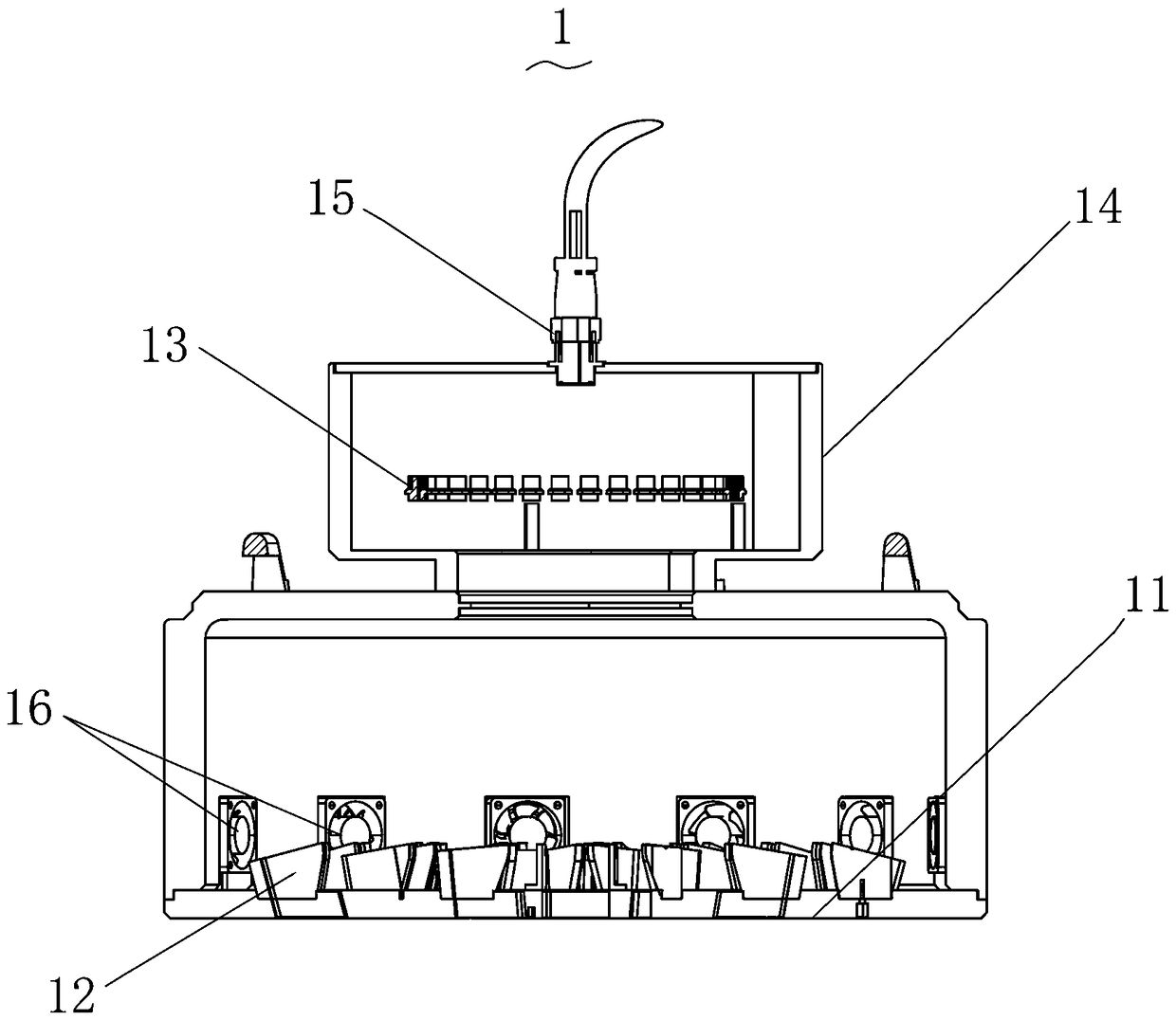

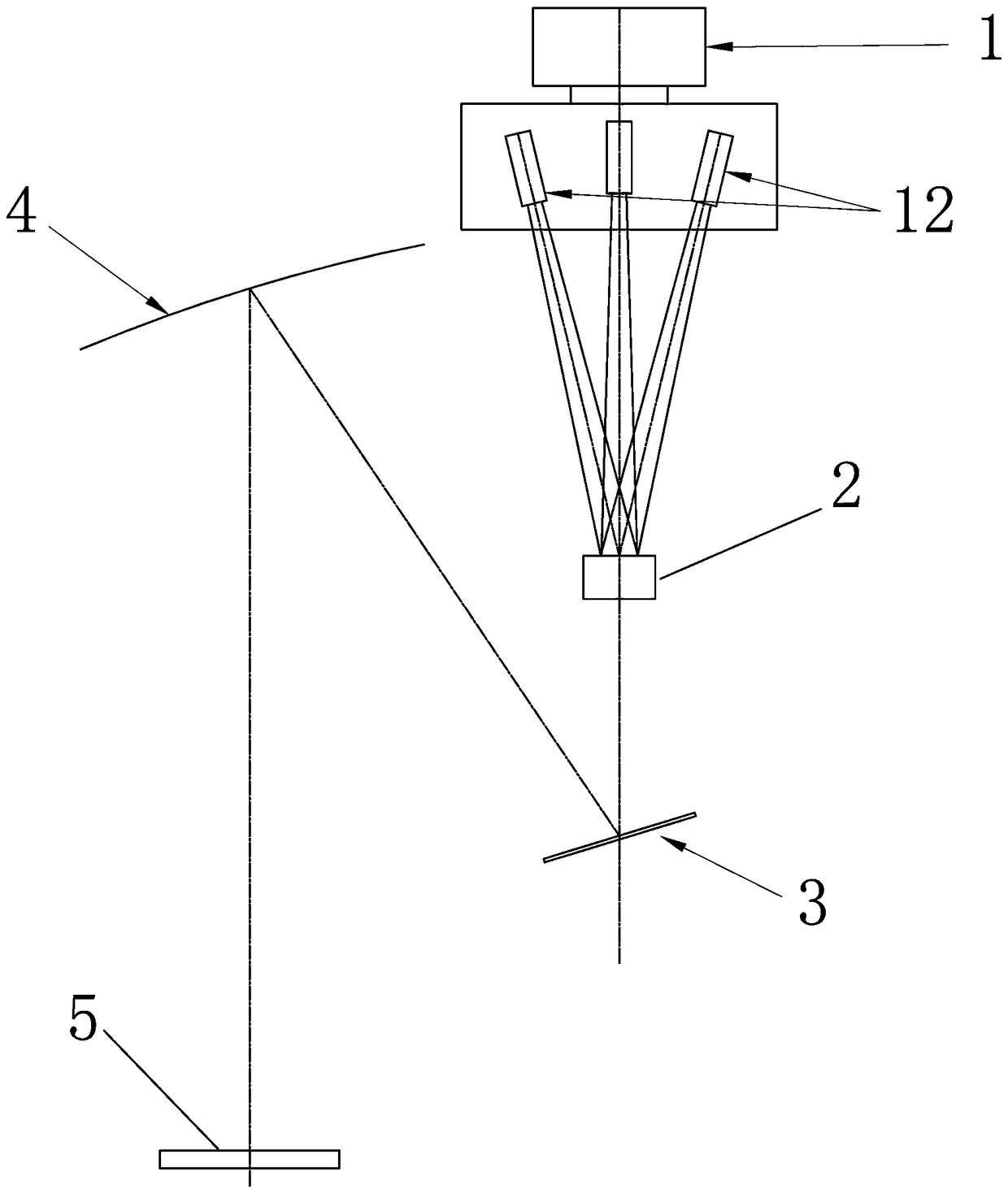

[0021] refer to figure 1 As shown, the present invention relates to an LED concentrating light source, including an LED concentrating light source device main body 1, the LED concentrating light source device main body 1 has a front mounting plate 11, a driving board 13 and a housing 14, and the housing 14 provides the front mounting plate 11 and the installation position of the driving board 13, and a plurality of LED lamp beads 12 are installed on the front mounting board 11, and the LED lamp beads 12 are electrically connected to the driving board 13; of light spots. The light spot reaches the light intensity required for exposure, which solves the problem of exposure operation caused by inconsistent attenuation of lamp beads o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com