Method for building whole rock uniaxial compression process creep model based on S function

A uniaxial compression, the whole process technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of the model creep equation, such as complex form, impossibility, and inconvenient application, so as to achieve convenient application and overcome segmentation Handling, function expression form simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

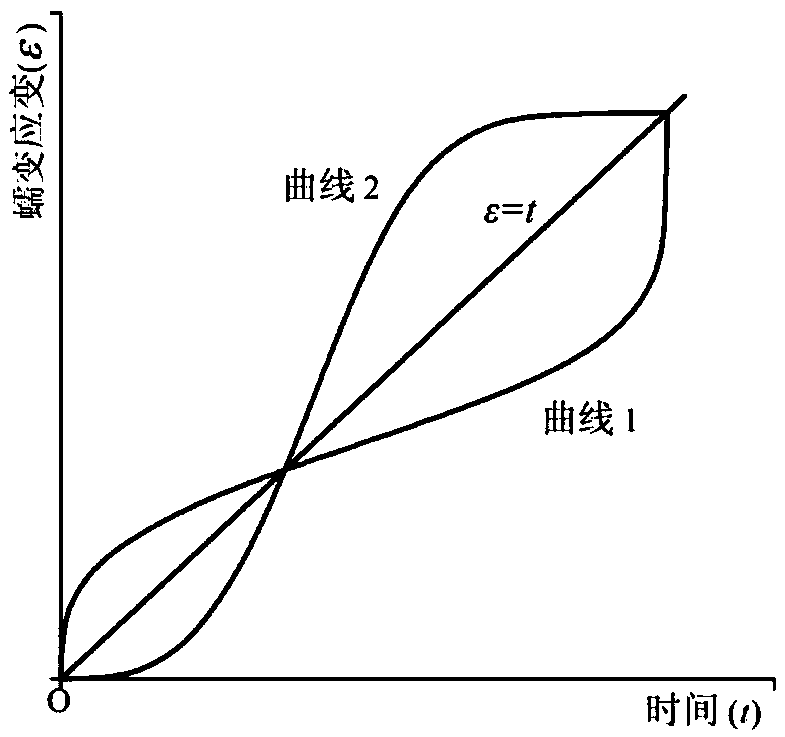

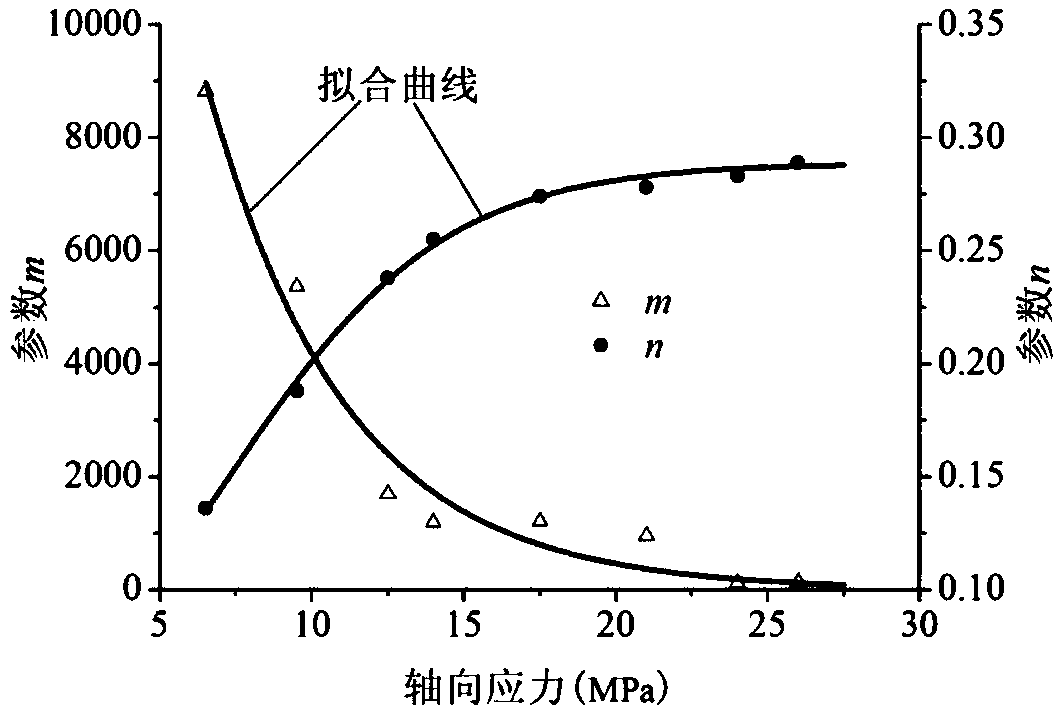

[0045] The present invention includes carrying out the uniaxial compression creep test of rock, drawing the symmetric curve of the creep curve in the whole process, determining the expression of the symmetric curve, determining the function expression of the creep model, determining the parameters of the creep model, and six steps of model verification, A symmetrical curve is an S-shaped curve.

[0046] Step 1, carry out rock uniaxial compression creep test;

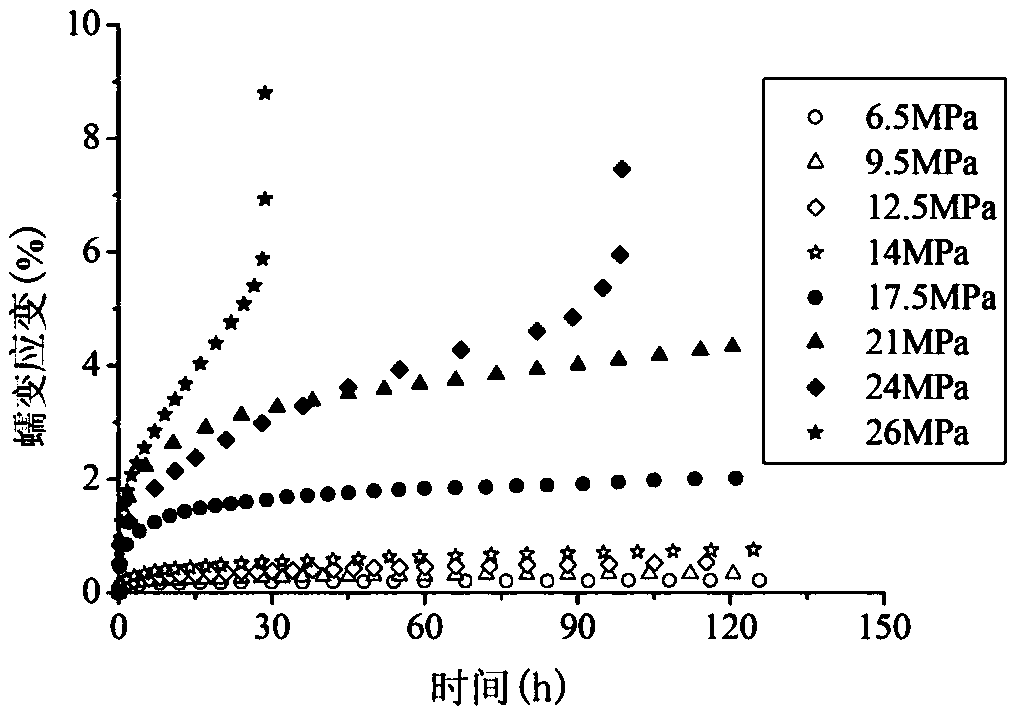

[0047] Using a single-stage loading method, different axial stress σ was carried out on a cylindrical salt rock specimen with a diameter of 50 mm and a height of 100 mm 1 =6.5, σ 2 =9.5, σ 3 =12.5, σ 4 =14, σ 5 =17.5, σ 6 =21, σ 7 = 24 and σ 8 =Uniaxial compression creep test under 26MPa to obtain the creep curve of salt rock under corresponding axial stress, see figure 1 .

[0048] see figure 1 , when...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com