Maneuverability hydrodynamic testing device and testing method of hydrojet propelled ship model

A technology of water jet propulsion and testing device, which is applied in the direction of measuring device, fluid dynamics test, machine/structural component test, etc. It can solve problems such as deviation and interaction without consideration, and achieve high precision, reasonable test method and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

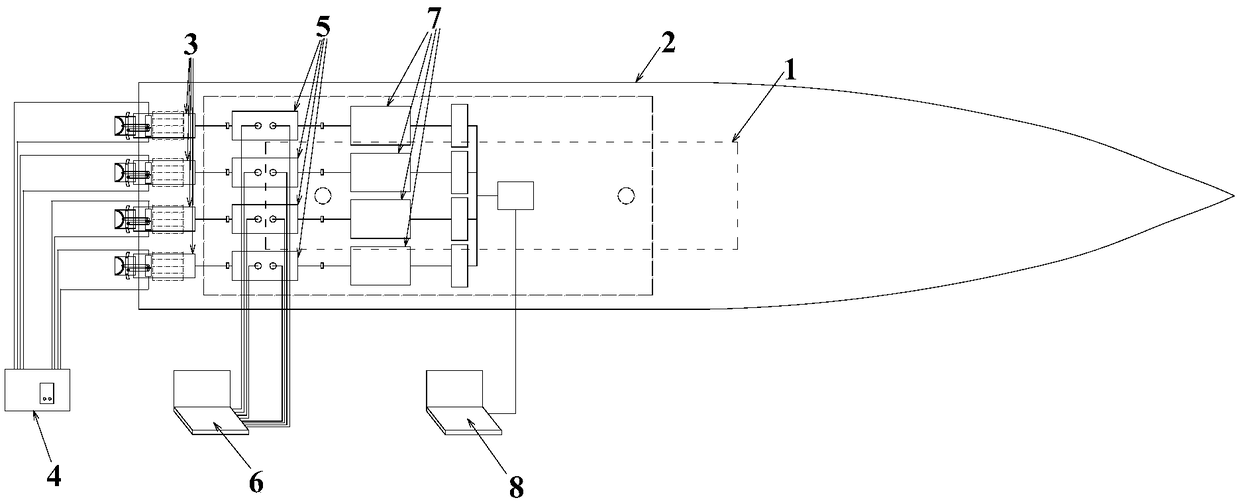

[0084] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 8 As shown, the control system 4 of the water jet propulsion device includes: a motion controller 20 , and the motion controller 20 controls the reversing bucket 14 and the nozzle diverter 15 .

[0085] In a further embodiment of the present invention, the water jet propulsion device control system 4 includes: a wireless signal receiver 22 , and the wireless signal receiver 22 is connected with the motion controller 20 .

[0086] In a further embodiment of the present invention, the control system 4 of the water jet propulsion device includes: a wireless signal remote controller 21 , and the wireless signal remote controller 21 is connected to a wireless signal receiver 22 for signals.

[0087] In a further embodiment of the present invention, the water jet propulsion device 3 is connected to the dynamic tester 5 through a shaft bracket.

[0088] In a further embodiment of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com