A high temperature resistant magnetic suction temperature sensor

A temperature measurement sensor and high temperature resistant technology, applied in the field of metallurgical technology, can solve the problems of inaccurate measurement data, hidden dangers of real-time continuous temperature measurement, and large error in measurement results, so as to achieve high measurement accuracy, reduce labor costs and waste of resources , measure the effect of accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0024] The present invention provides a high-temperature-resistant magnetic suction type temperature-measuring sensor aiming at the existing problems of large errors in measurement results, inaccurate measurement data, inability to realize real-time continuous temperature measurement and potential safety hazards.

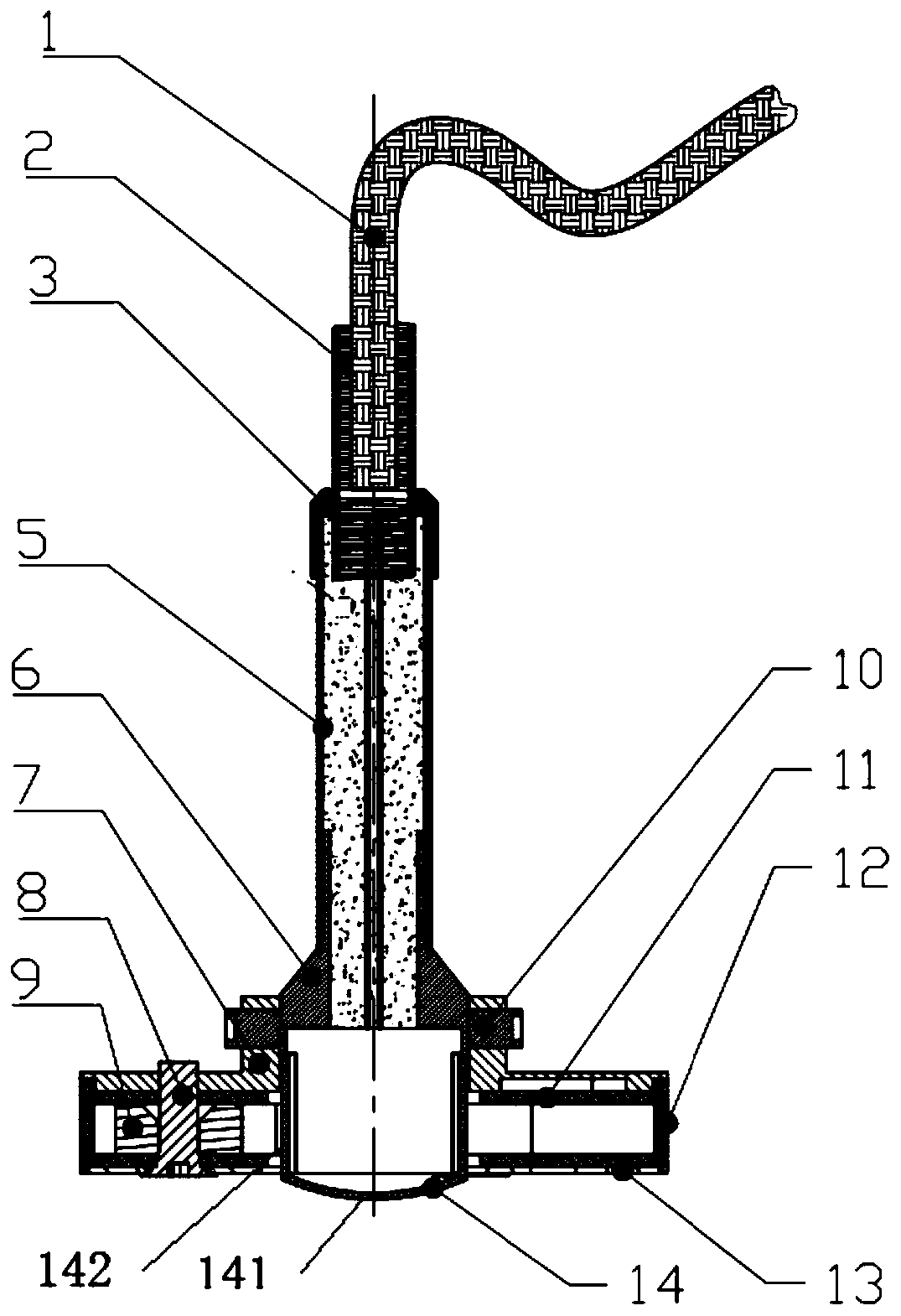

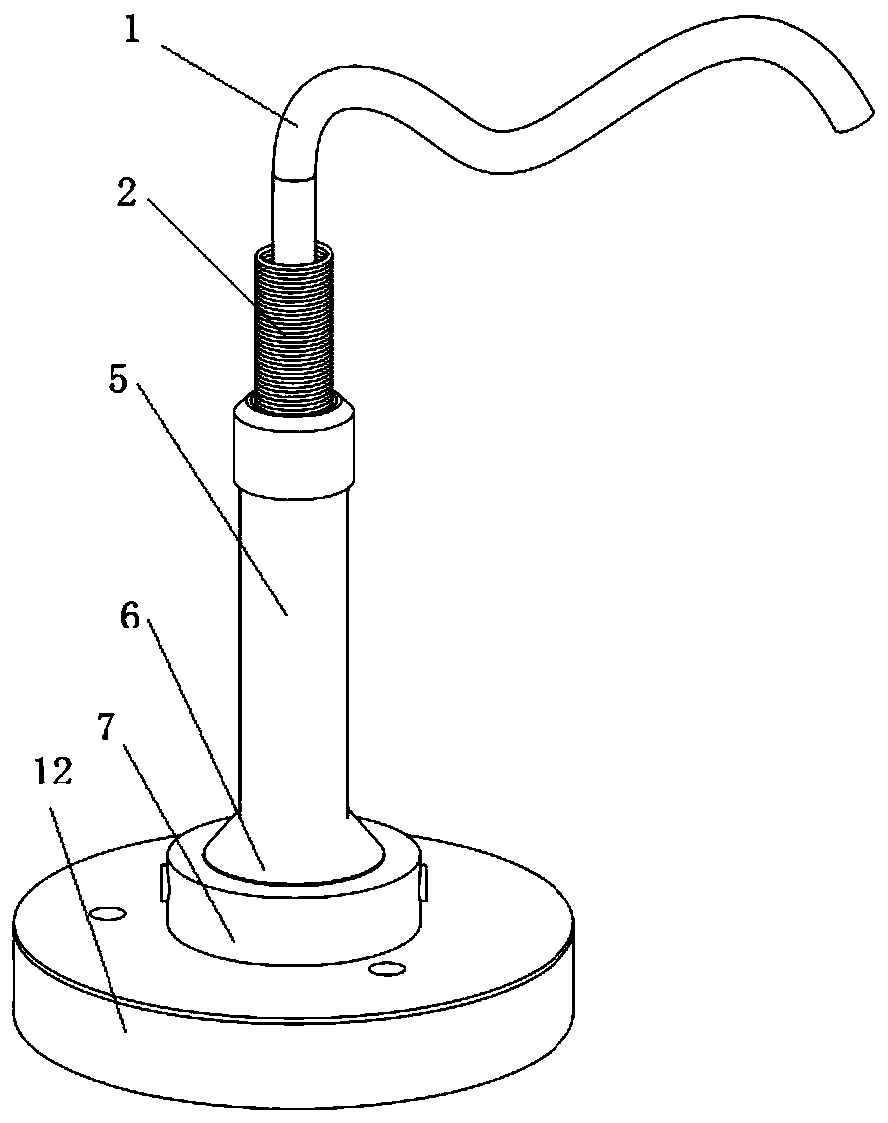

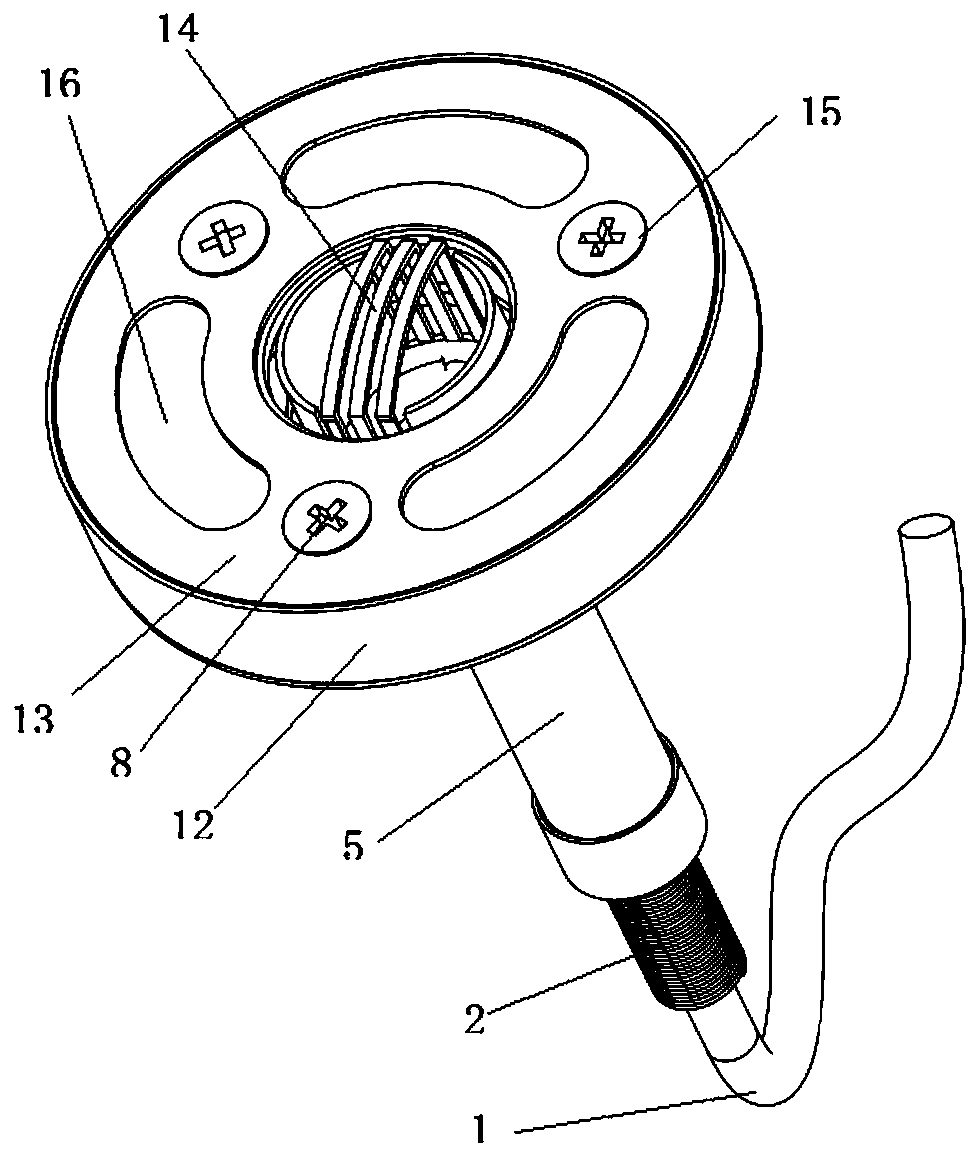

[0025] Such as Figure 1-3 As shown, the embodiment of the present invention provides a high-temperature-resistant magnetic suction temperature sensor, including a base, an asbestos gasket 11 and a strong magnetic high-temperature-resistant magnet 9 are arranged inside the base, and a copper film-type sensing structure 14 passes through the base from bottom to top, the top of the base is connected to the bottom of the sensor 6, the copper thin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com