Assembly type joint based on austenite SMA-steel plate set and martensite SMA bars

A martensite and austenitic technology, applied in the field of prefabricated joints, can solve the problems of weakened energy dissipation capacity, reduced joint stiffness, weak energy dissipation capacity, etc., to optimize energy dissipation performance, improve residual deformation, and facilitate assembly construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

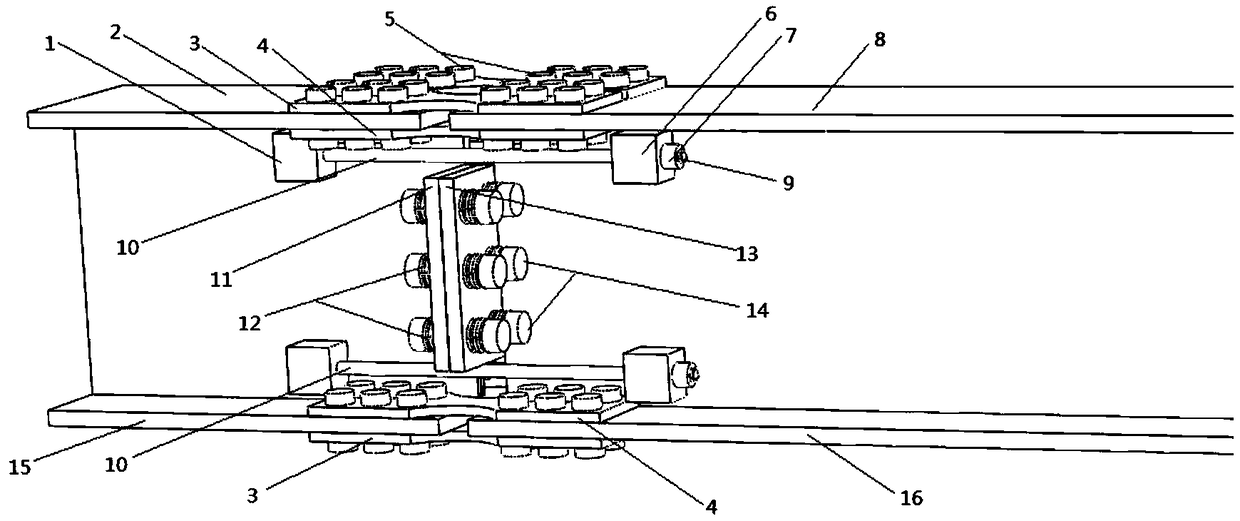

[0033] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0034] The present invention provides an assembled node based on austenitic SMA-steel plate group and martensitic SMA rod, such as figure 2 As shown, including 1. I-shaped steel beams 2, 4 dog-bone connecting steel plates, 4 austenitic SMA dog-bone connecting plates 3, 4 martensitic SMA rods 4, austenitic SMA disc springs 5 , 4 threaded anchor blocks, 4 unthreaded anchor blocks 5, 4 high-strength steel rectangular end plates, of which:

[0035] 1. After the standardized production and processing of the above-mentioned components in the factory, pre-positioning is carried out on the factory assembly line, and holes are made for the connection positions of the steel beams, dog-bone connecting plates, and high-strength bolts on the rectangular end plates o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com