Beam column mortise and tenon joint structure comprising bendable piece and manufacturing method of beam column mortise and tenon joint structure

A bending piece, mortise and tenon technology, which is applied to building components, building structures, earthquake resistance, etc., can solve the problems of unstable damage and large occupied space, and achieve the effects of improving brittle damage, simple structure, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

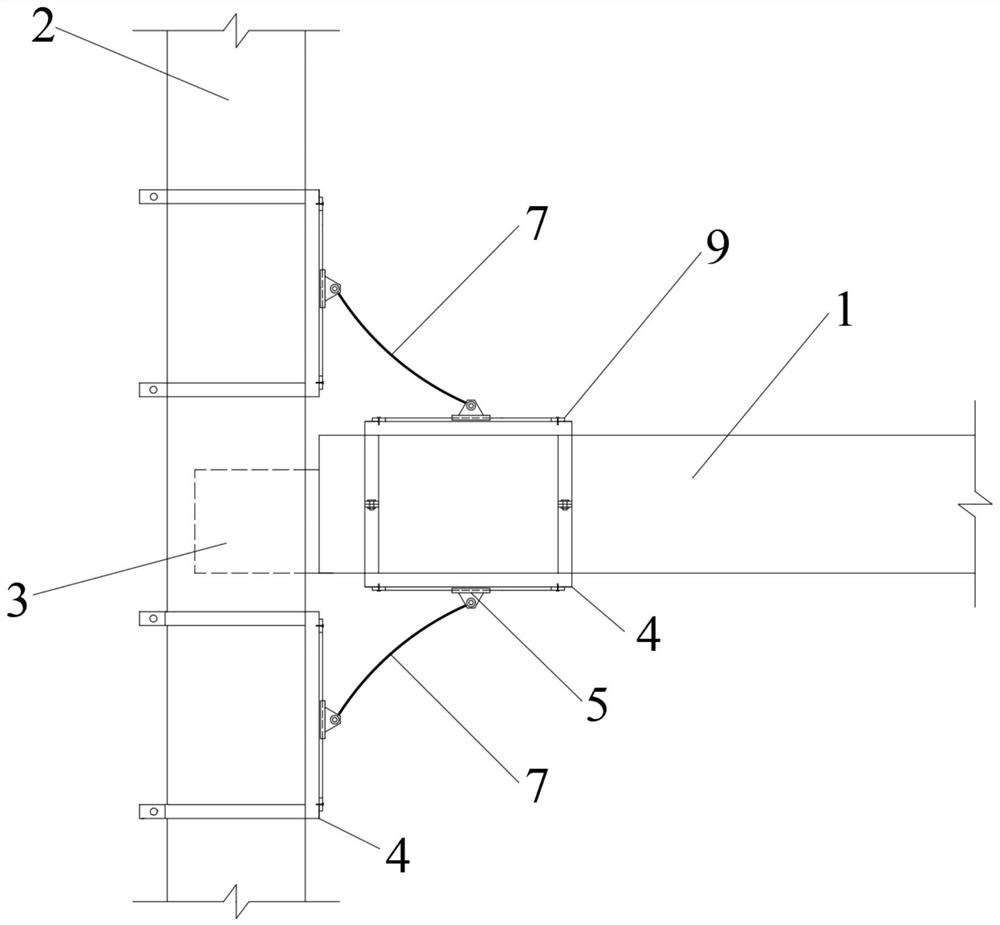

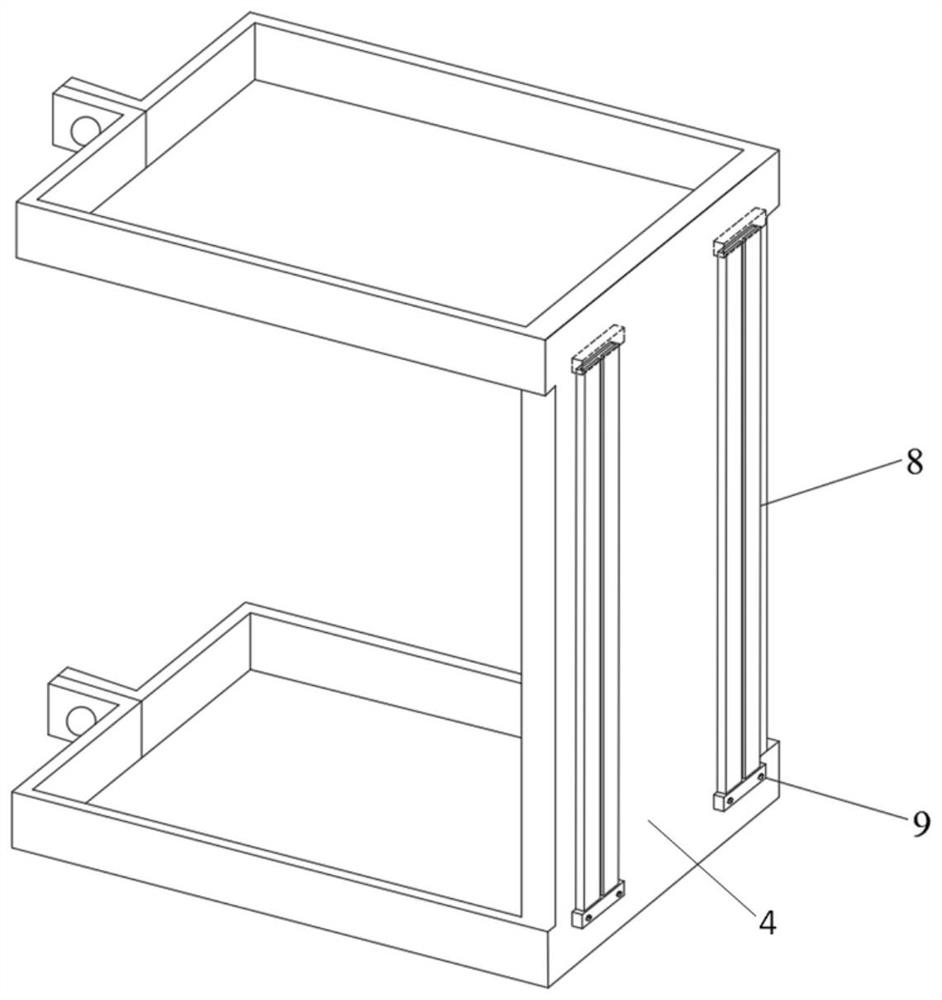

[0041] A beam-column mortise and tenon structure with bendable sheets, such as figure 1 , the structure includes wooden beams 1 and wooden columns 2 connected by mortise and tenon joints, and also includes a bendable piece 7; four slidable hinged supports 5 are arranged on the wooden beam 1 and wooden column 2; both ends of the bendable piece 7 are connected to The slidable hinged support 5 is hinged. The cross-sectional shape of the wooden beam 1 and the wooden column 2 is rectangular, and the wooden column 2 is provided with a mortise, and the wooden beam 1 is provided with a mortise, and the two are connected to the mortise and tenon joint 3 .

[0042] The invention greatly improves the pull-out resistance and rotation resistance of the beam-column mortise and tenon joint, and the bendable piece 7 is used as a replaceable component, which reduces the repair cost of the joint, improves the repair efficiency, and improves the traditional joint to a certain extent. The beam-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com